Method and device for controlling morphology of boehmite

A boehmite and morphology technology, applied in the direction of alumina/hydroxide, etc., can solve problems such as increased production costs, inability to convert into products, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

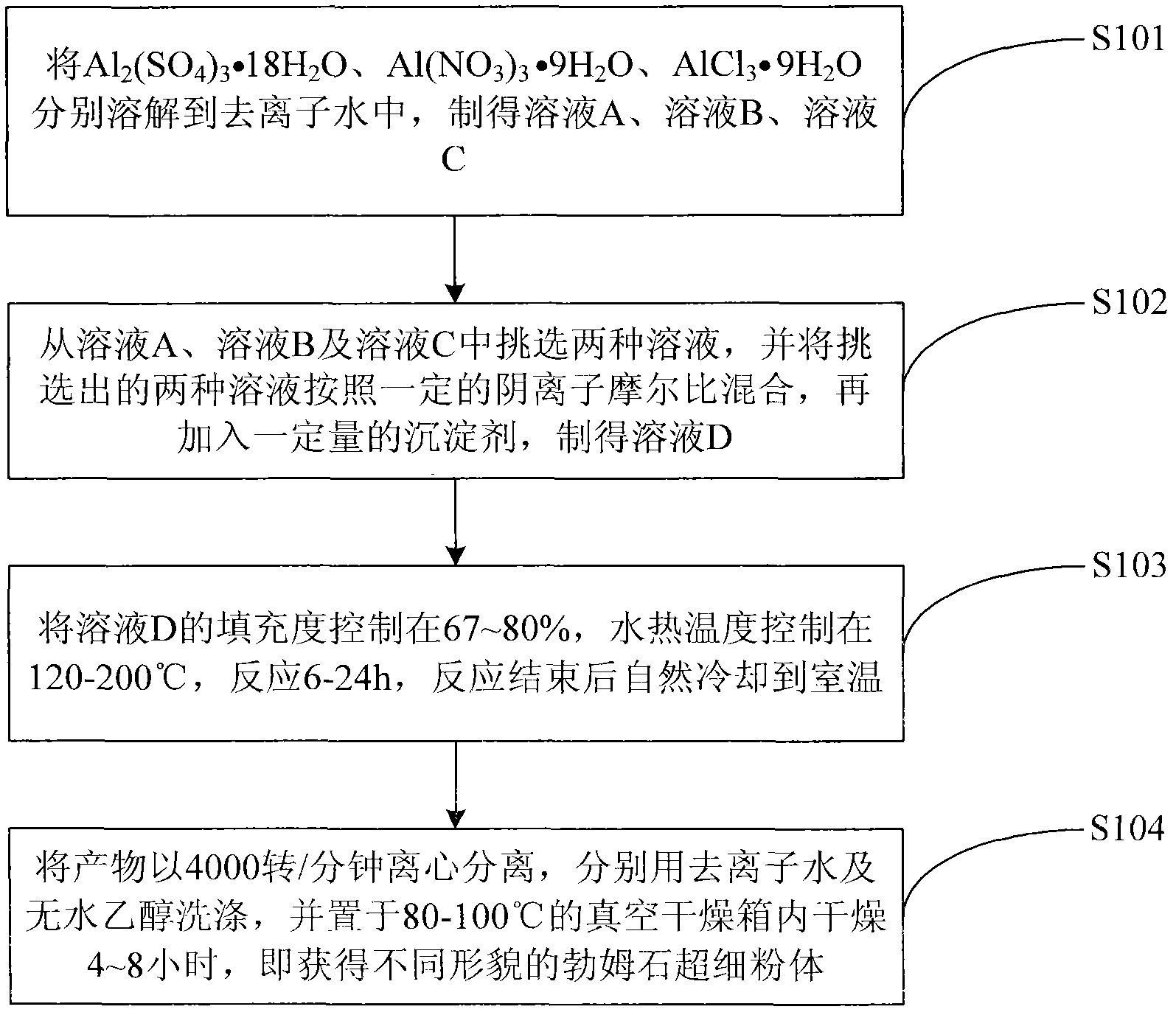

Method used

Image

Examples

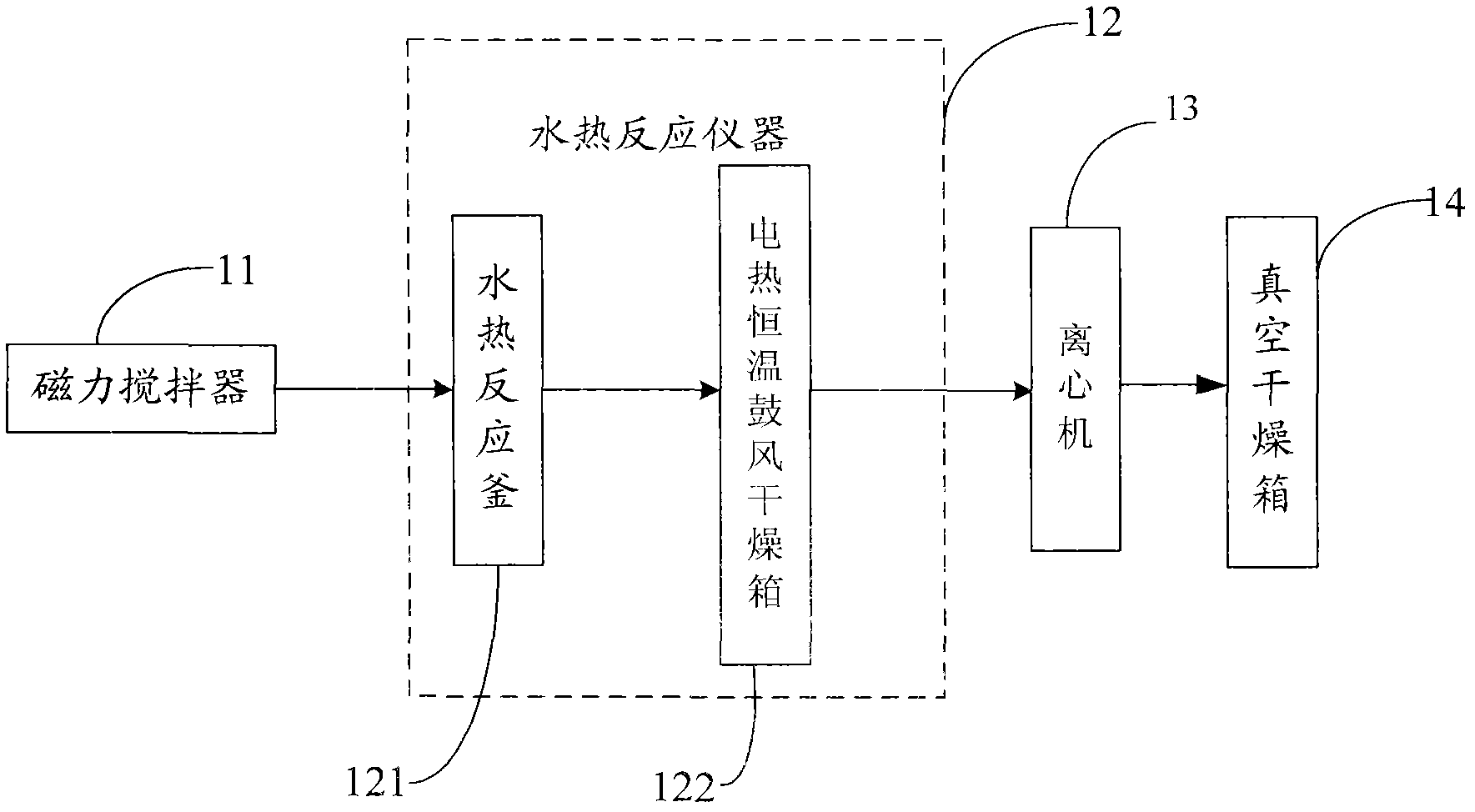

Embodiment 2

[0048] Example 2: First, analytically pure Al 2 (SO 4 ) 3 18H 2 O, Al(NO 3 ) 3 9H 2 O was added to two containers respectively, deionized water was added, stirred on a magnetic stirrer 11 to dissolve it, and Al 3+ Transparent solutions with equal or different concentrations are marked as solution A and solution B respectively; secondly, according to the anion molar ratio of 1:4.5, that is, SO 4 2- : NO 3 - =1: 4.5, add in hydrothermal reactor 121 liner and mix, then add a certain amount of urea as precipitating agent, the addition of urea is to precipitate all Al 3+ 150% of the required theoretical demand, continue to stir for half an hour, and make a transparent solution C; then, control the filling degree of solution C in the hydrothermal reaction kettle 121 at 75%, seal the hydrothermal reaction kettle 121, and place it In the electrothermal constant temperature blast drying oven 122, control the hydrothermal temperature at 150°C, react for 24 hours, and cool to r...

Embodiment 3

[0049] Example 3: First, analytically pure Al 2 (SO 4 ) 3 18H 2 O, Al(NO 3 ) 3 9H 2 O was added to two containers respectively, deionized water was added, stirred on a magnetic stirrer 11 to dissolve it, and Al 3+ Transparent solutions with equal or different concentrations are marked as solution A and solution B respectively; secondly, according to the anion molar ratio of 1:3, that is, SO 4 2- : NO 3 - =1: 3, add in hydrothermal reactor 121 liner and mix, then add a certain amount of urea as precipitating agent, the addition of urea is to precipitate all Al 3+ 100% of the required theoretical demand, continue to stir for half an hour, and make a transparent solution C; then, control the filling degree of solution C in the hydrothermal reaction kettle 121 at 70%, seal the hydrothermal reaction kettle 121, and place it In the electrothermal constant temperature blast drying oven 122, control the hydrothermal temperature at 180°C, react for 12 hours, and naturally coo...

Embodiment 4

[0050] Example 4: First, the analytically pure Al 2 (SO 4 ) 3 18H 2 O, AlCl 3 9H 2 O was added to two containers respectively, deionized water was added, stirred on a magnetic stirrer 11 to dissolve it, and Al 3+ Transparent solutions with equal or different concentrations are marked as solution A and solution B respectively; secondly, according to the anion molar ratio of 1:18, that is, SO 4 2- :Cl - =1:18, add in hydrothermal reactor 121 liner and mix, then add a certain amount of urea as precipitating agent, the addition of urea is to precipitate all Al 3+ 125% of the required theoretical demand, continue to stir for half an hour, and make a transparent solution C; then, control the filling degree of solution C in the hydrothermal reaction kettle 121 at 80%, seal the hydrothermal reaction kettle 121, and place it In the electrothermal constant temperature blast drying oven 122, control the hydrothermal temperature at 120°C, react for 24 hours, and cool to room tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com