Vehicular gantry crane coal shipping accessory

A vehicle-mounted, door crane technology, applied in packaging, transportation, packaging, containers, etc., can solve problems such as leakage, dust, and grabs that cannot be closed tightly, and achieve the effect of improving unloading efficiency and simplifying process links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

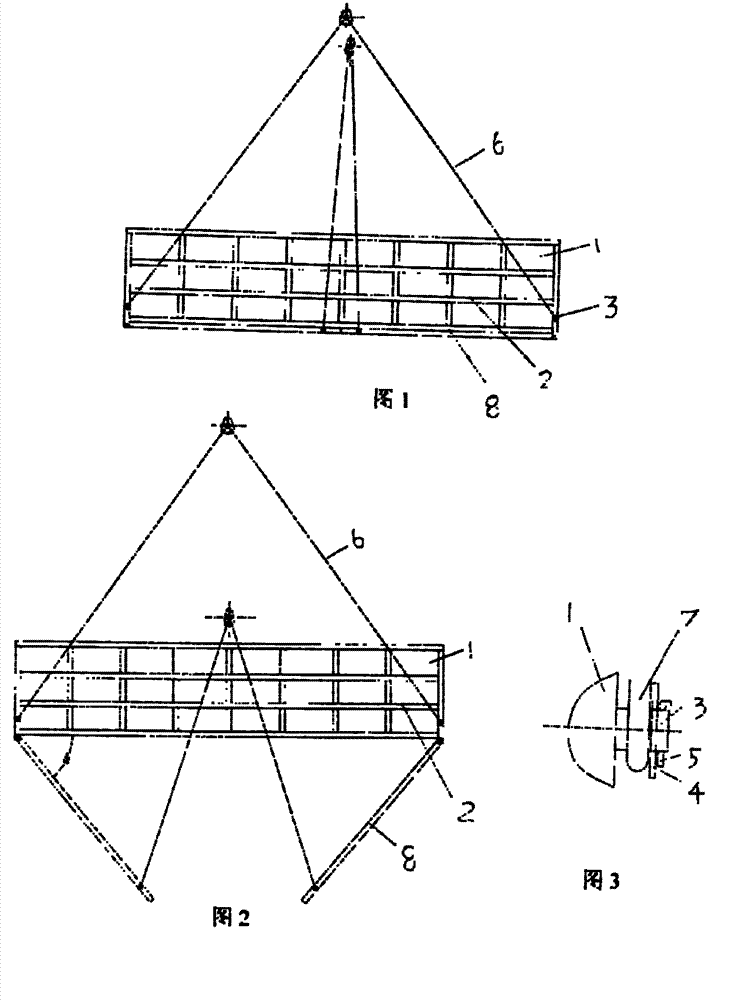

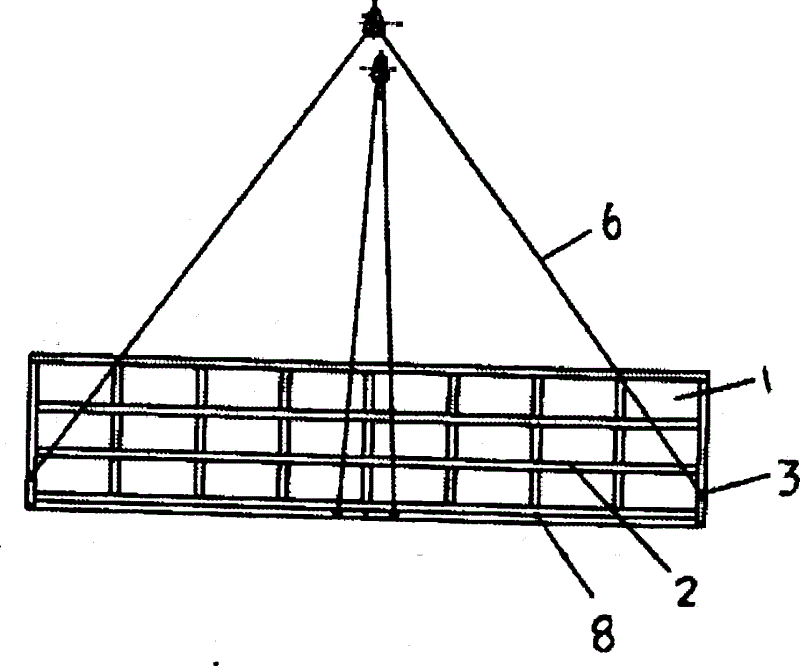

[0016] A vehicle-mounted gantry crane coal loading attachment, an open rectangular box, the wall panels around the rectangular box are reinforced grids welded by C-shaped steel, the bottom of the rectangular box is made of Two bottom valves that can be unscrewed downwards are formed; cargo box lifting point devices are equipped outside the wall panels around the rectangular casing, and cargo box lifting point devices are equipped with cargo box lifting point devices on the sides of the two bottom valves close to the slit.

[0017] The container lifting point device has a lifting point pile connected to the box body, a safety retaining ring is sheathed on the outer end of the lifting point pile, and a safety latch is arranged on the lifting point pile outside the safety retaining ring. on the hanging point pile

[0018] The box structure reinforced by C-shaped steel is used to check and calculate the strength and stiffness to meet the requirements of frequent hoisting;

[0019...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com