Packaging bag unpacking device capable of binding materials

A technology for packaging bags and materials, applied in the field of packaging bag unpacking devices, can solve the problems that materials cannot be separated from straps and bags, and straps cannot be separated from materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

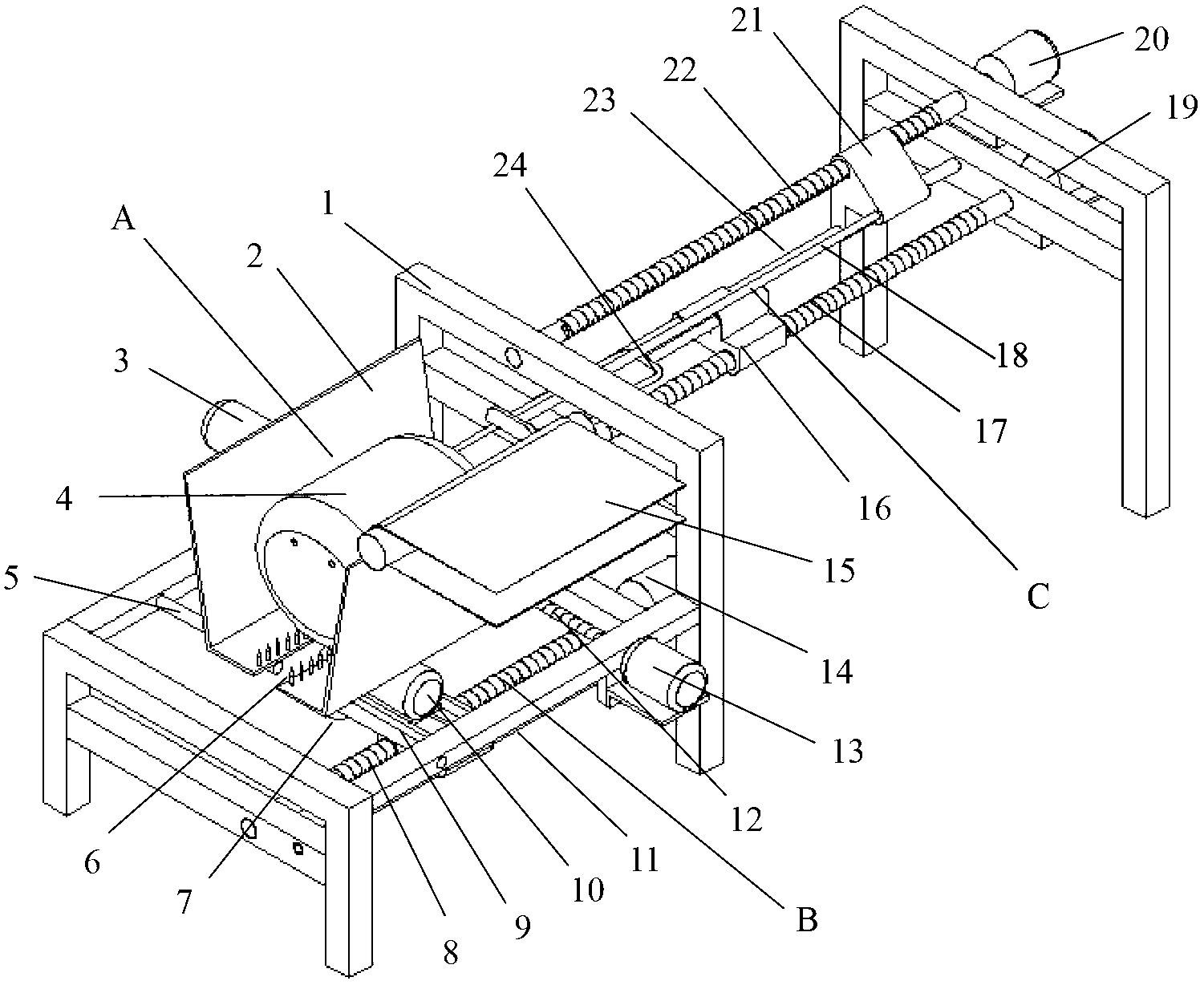

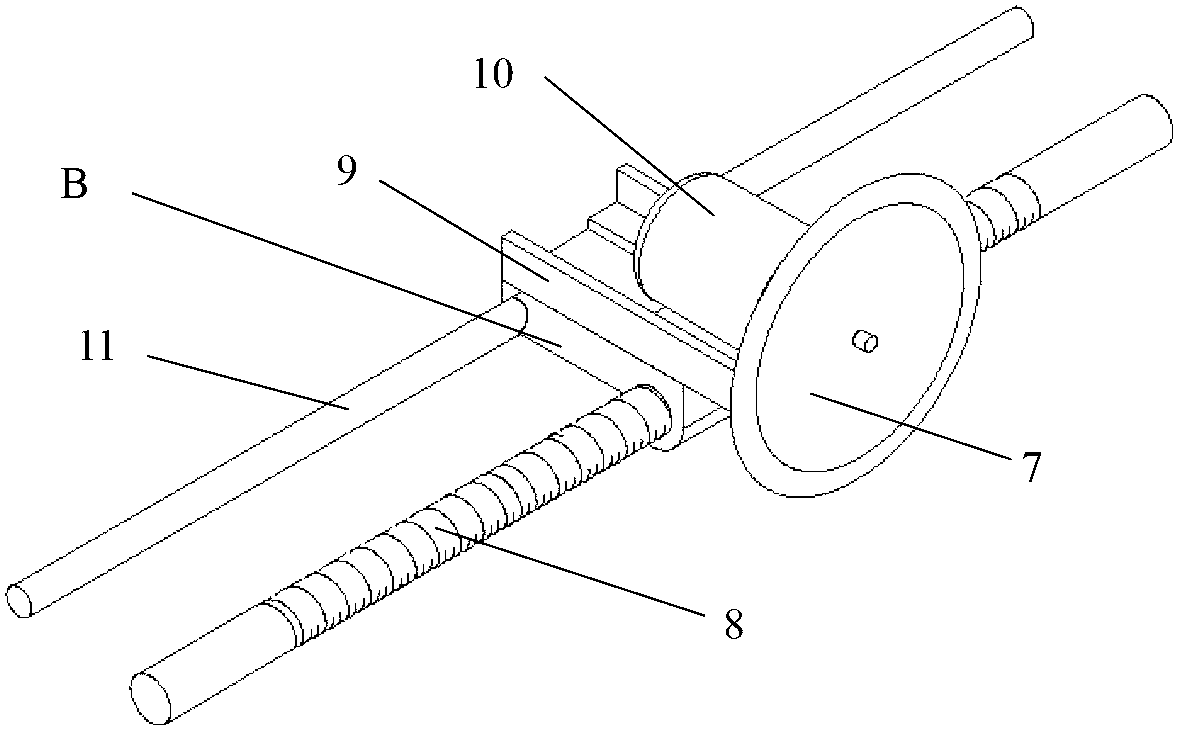

[0025] Such as figure 1 As shown, the present invention is mainly made up of hopper feeding device A, cutting feeding device B, fork and push rod feeding device C and frame 1, and each feeding device presses Figure 5-10 The unpacking of the packaging bag is realized by actions in sequence, as follows:

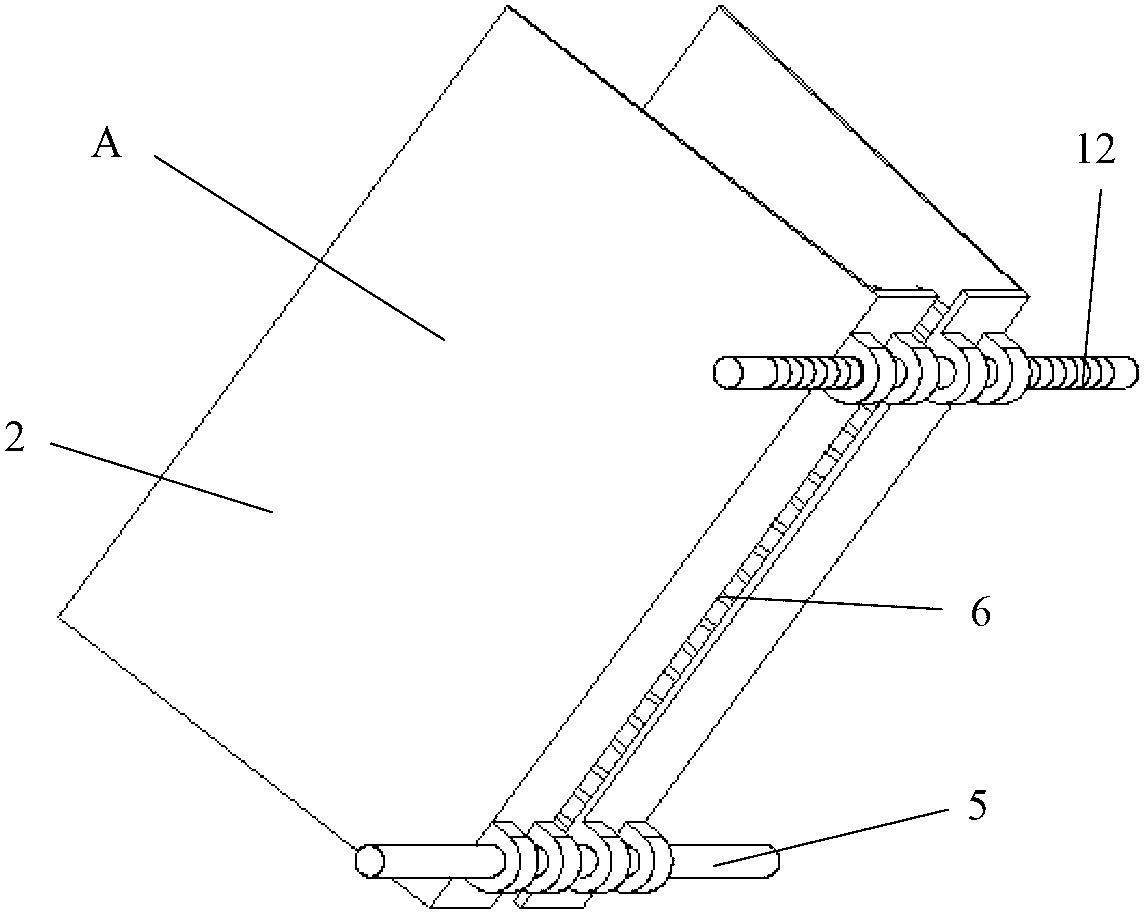

[0026] The packaging bag 4 is transported into the hopper 2 through the conveyor belt 15, and the hopper 2 clamps the packaging bag 4 under the drive of the hopper screw 12. In addition, when the packaging bag 4 falls into the hopper due to gravity, the protrusion at the bottom of the hopper 2 Nail 6 is stuck into packing bag, can play the effect of fixing, see Figure 6 .

[0027] The fork 24 moves along the light bar 23 under the drive of the fork lead screw 17, and the packaging bag 4 is interspersed. On the one hand, the material bag and the strap are picked up, and on the other hand, the effect of fixing the packaging bag is also played. See Figure 7 .

[0028] After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com