Underwater real-time surface dirt cleaning and detecting device for optical-fiber laser

A surface dirt, fiber laser technology, applied in the field of cleaning, can solve the problems of reduced signal sensitivity, sonar board cleaning, inability to use submarines, etc., to achieve the effect of reducing labor intensity, high degree of automation, and reducing cleaning costs and cleaning time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

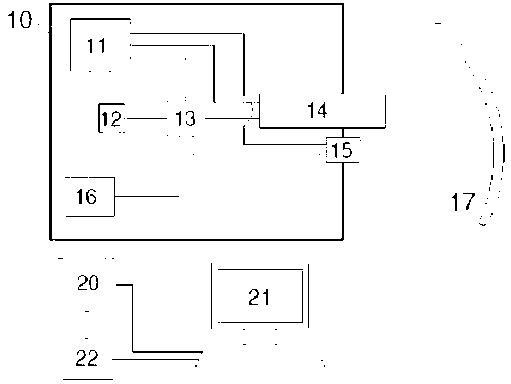

[0014] Combine below figure 1 The device of the present invention will be described in detail. The device realizing the present invention comprises: underwater cleaning device 10, power supply 20, wireless signal device one 22, computer 21, power supply circuit 35, 36 and control circuit 44, wherein in the airtight casing of underwater cleaning device 10, power supply 11, GPS Positioning device 12, control device 13, fiber laser 14, CCD sensor 15, wireless signal device 2 16, power line and control line. In the airtight casing of the underwater cleaning device 10, the power supply 11 is respectively connected to the GPS positioning device 12, the control device 13, the fiber laser 14, the CCD sensor 15 and the wireless signal device 16 through the power line; the control device 13 is respectively connected to the GPS through the control line Positioning device 12, fiber laser 14, CCD sensor 15 and wireless signal device 2 16. In the operator terminal, the power supply 20 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com