Small tip lorry

A dump truck and small-sized technology, which is applied in the direction of tilting and carrying vehicles, etc. It can solve the problems of limited tipping angle, inability to ensure clean dumping of materials, flexible adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

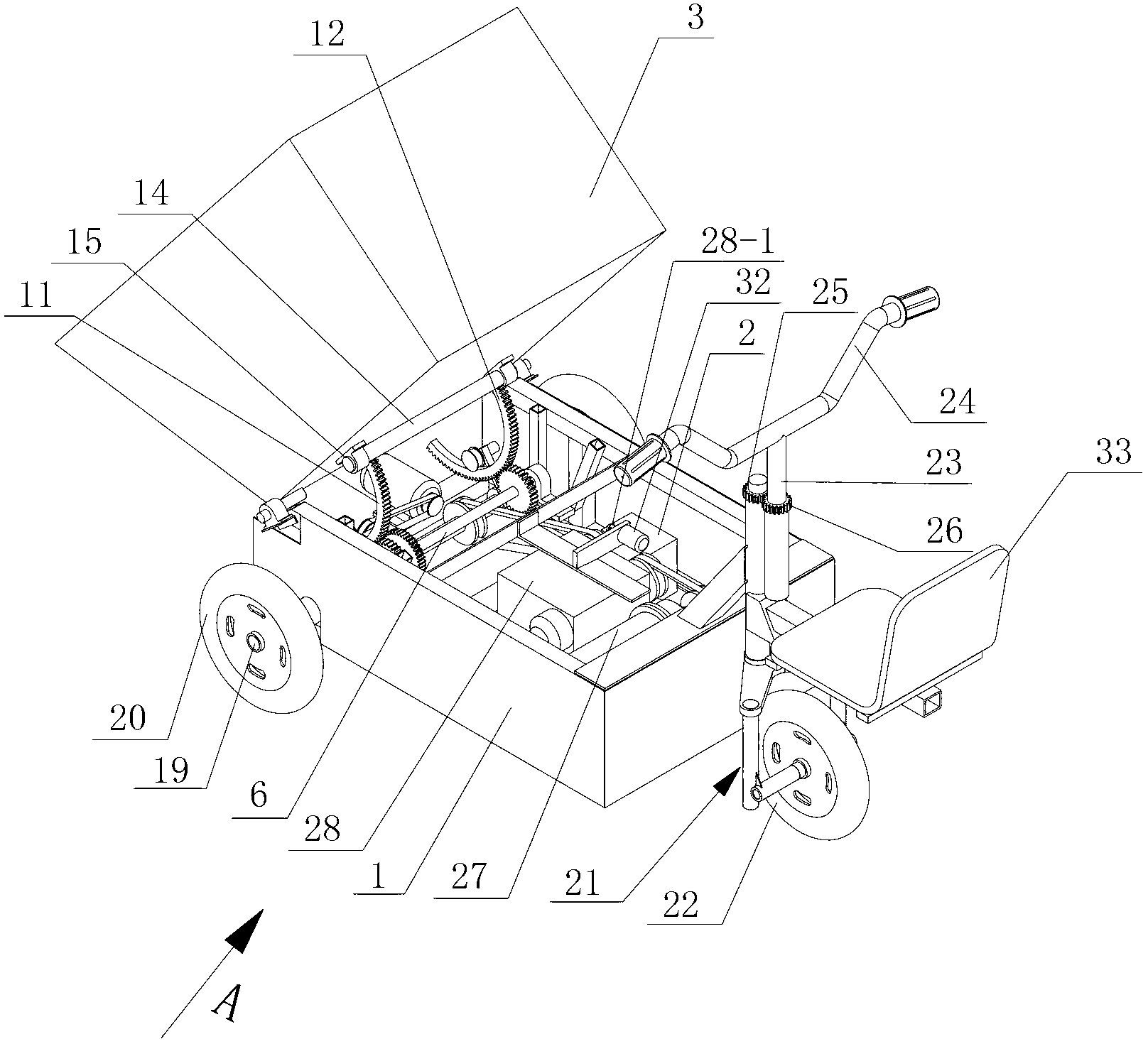

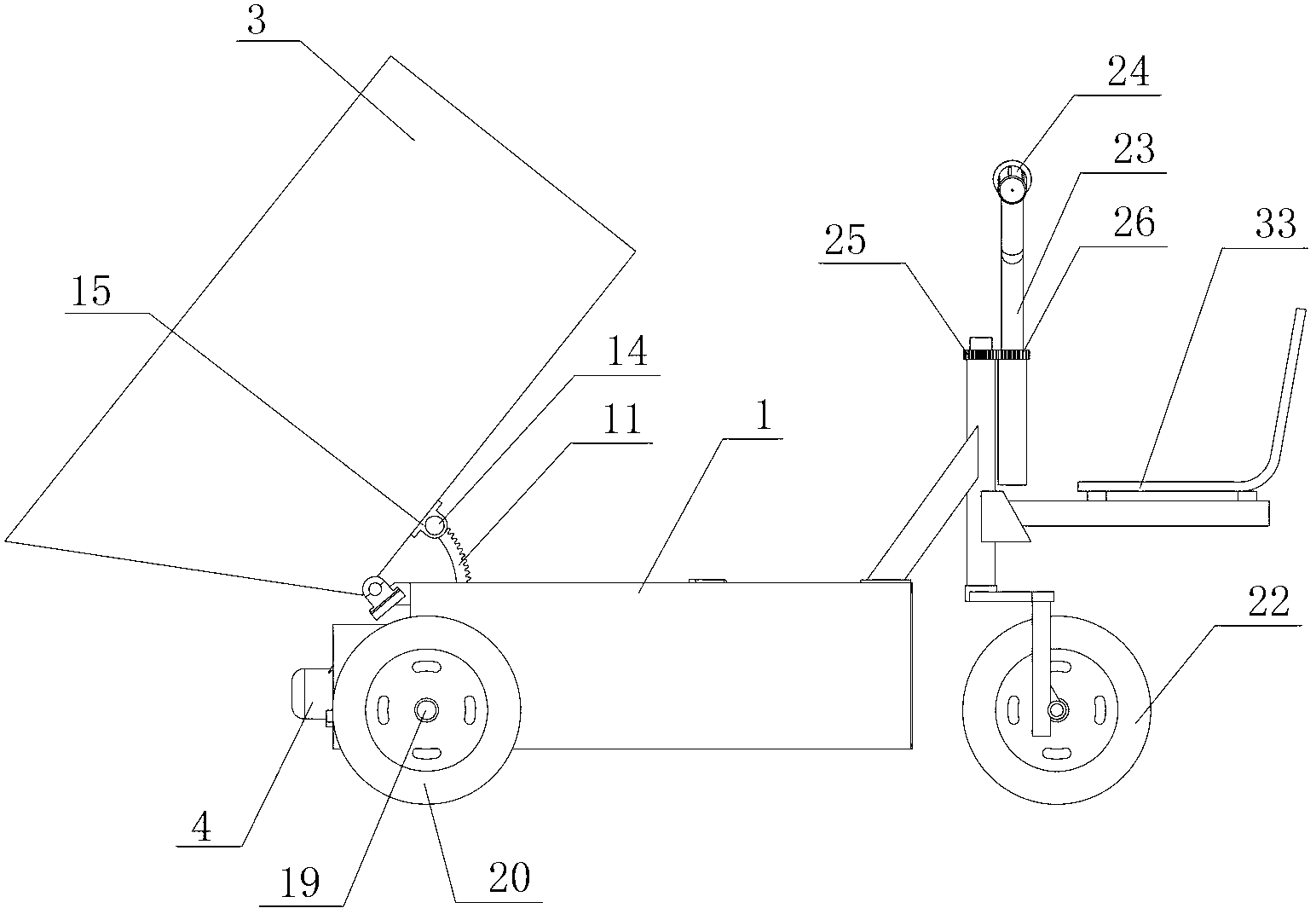

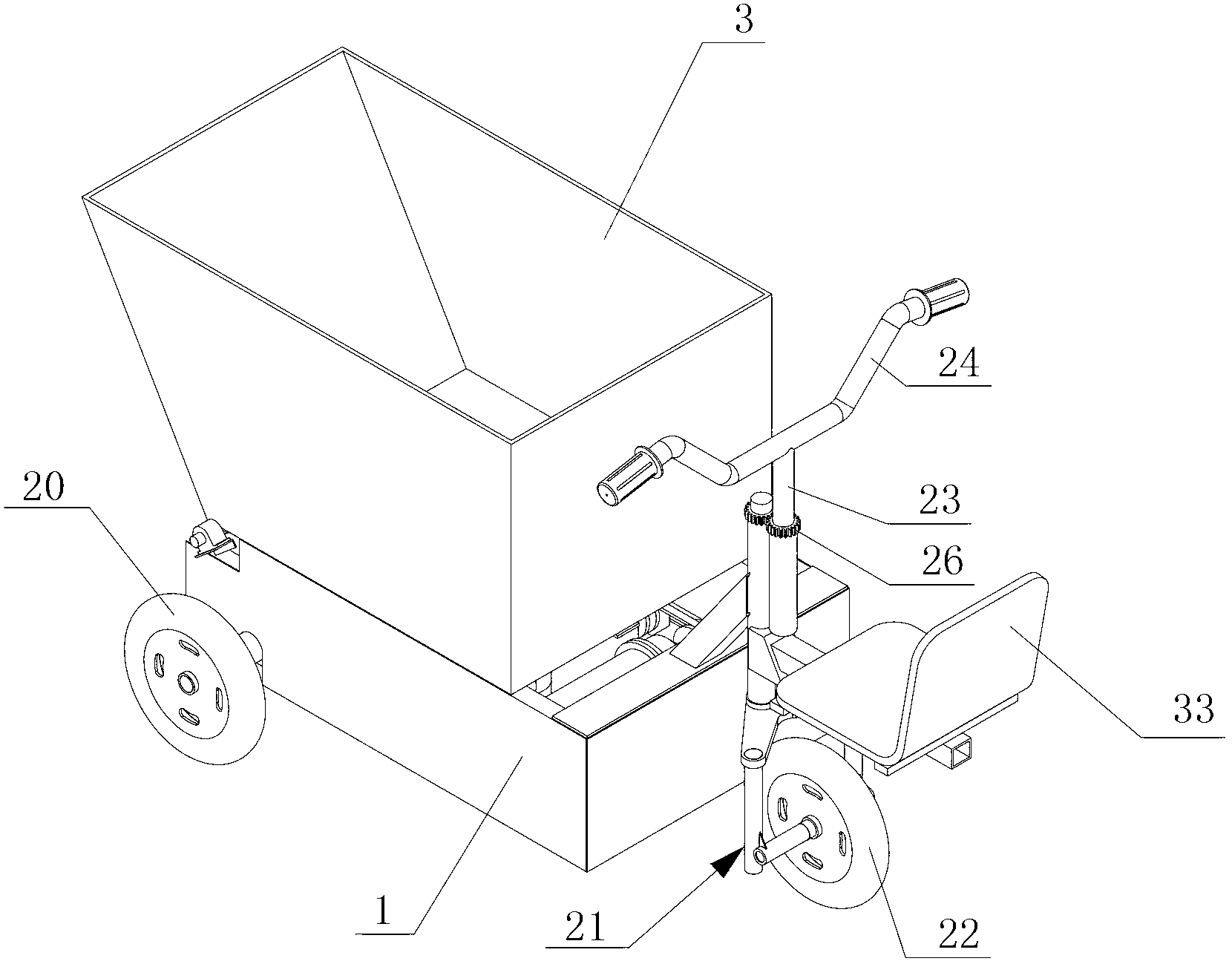

[0020] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0021] see Figure 1-5 , A small dump truck, including a frame 1, a battery 2, a travel steering mechanism, a hopper 3, a tipping drive mechanism and a seat 33, and the end of the hopper away from the seat is rotatably connected to the frame. The tipping drive mechanism is composed of a first motor 4, a speed reducer 5 connected to the first motor, and a gear transmission structure arranged between the speed reducer and the hopper. The gear transmission structure consists of a rotatable support shaft 6 installed in the vehicle frame, and a first gear 7 and a second gear 8 that are respectively fixed on the output shaft of the reducer and meshed with the support shaft, and are fixed on the support shaft symmetrically. The third gear 9 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com