Drilling fixture combined device

A combined device and drilling jig technology, applied in positioning devices, clamping, manufacturing tools, etc., can solve the problems of difficult processing and different sizes, and achieve the effects of quick operation, reduced friction, and guaranteed processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

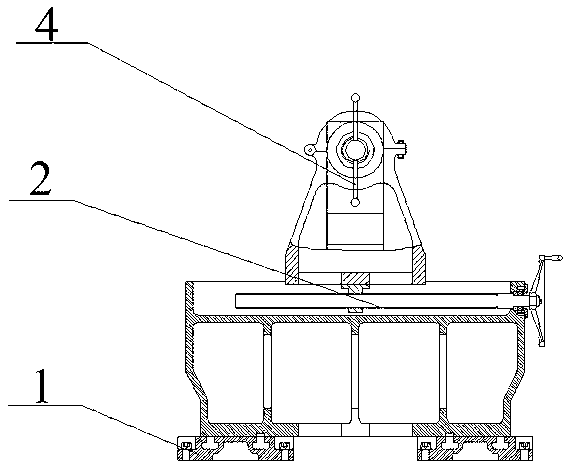

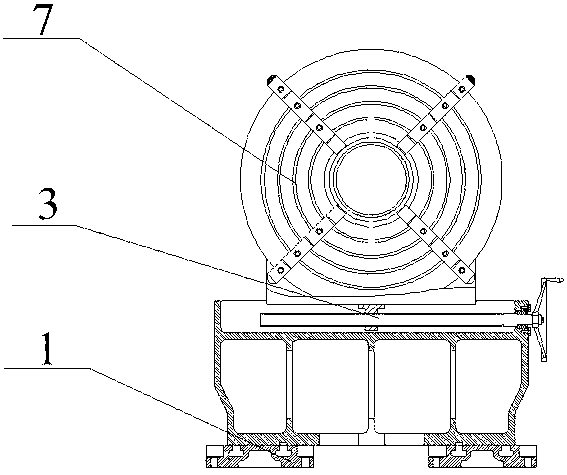

[0010] Such as figure 1 , figure 2 , image 3 As shown, the present invention includes a base 1, a first clamp device 2 and a second clamp device 3 are arranged in a line on the base 1, the first clamp device 2 includes a handle 4, a thimble 5, and a support frame 6, and the handle 4 is fixed on the end of the thimble 5 The thimble 5 is fixed on the support frame 6; the second fixture device 3 includes a four-jaw chuck 7 and a rotating shaft 8, and the four-jaw chuck 7 is fixedly connected to the end of the rotating shaft 8; the top of the support frame 6 is equipped with a bracket 9. The center of the bracket 9 is facing the thimble 5; the bracket 9 is a frame structure with a hollow center; the bracket 9 is fitted with a copper sleeve 10, which can reduce friction on the workpiece.

[0011] The first clamping device 2 and the second clamping device 3 are respectively located at both ends of the workpiece, and the workpiece is clamped and positioned. At the same time, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com