Device and method for homogenizing high-temperature melt

A high-temperature melt and melting pool technology, applied in chemical instruments and methods, mixers with rotating stirring devices, transportation and packaging, etc., can solve difficult problems and achieve long life, strong stirring ability, and large stirring capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

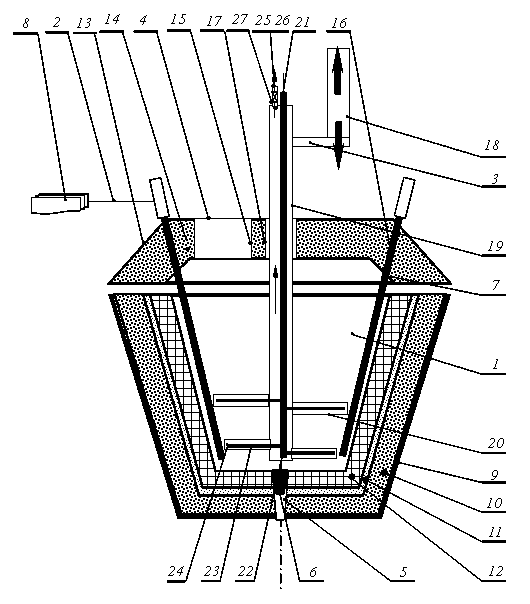

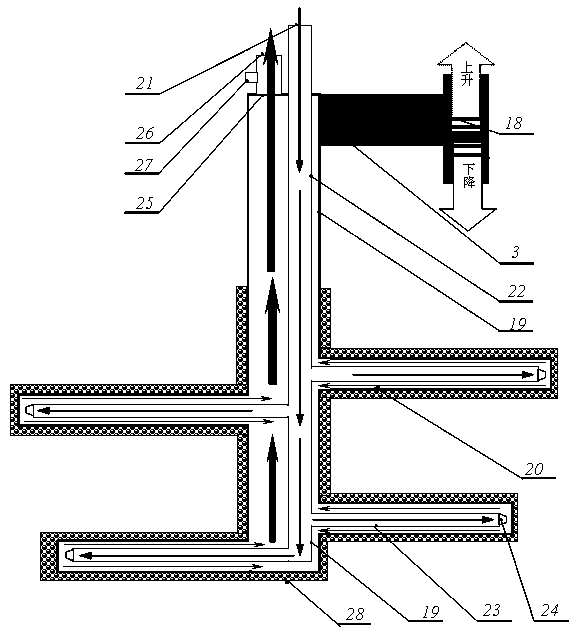

[0023] The homogenization device provided by the present invention consists of three parts: a melting tank 1, a stirring system and a heating system.

[0024] The thermal insulation furnace lining material of the melting tank of the device of the present invention is refractory light aggregate castable or refractory fiber particle castable or refractory foam concrete, and their materials are mainly high alumina or mullite or corundum or aluminum silicate , the working furnace lining material is made of dense corundum refractory bricks or dense zirconia corundum refractory bricks, the airgel coating is made of alumina or mullite or zirconia or silicon oxide, and the furnace cover lining is cast with refractory light aggregate It is formed by integral casting of refractory fiber granule castable or refractory foam concrete.

[0025] The stirring system includes a transmission part 18, a hollow stirring rod 19 and a hollow stirring blade 20 on the stirring rod. The distribution o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com