Anti-burying tilt switch

A tilt switch and anti-bury technology, applied in electrical switches, electrical components, circuits, etc., can solve the problems of inability to reset, easy to be buried by blanking, buried by tilt switches, etc., and achieve the effect of sensitive response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

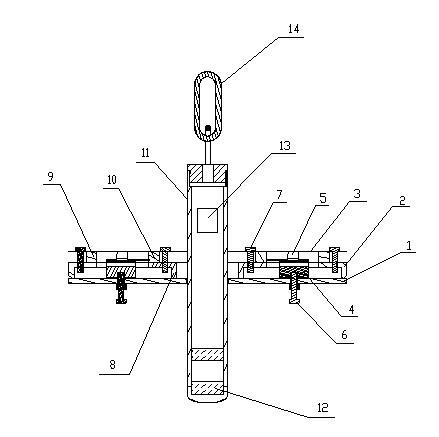

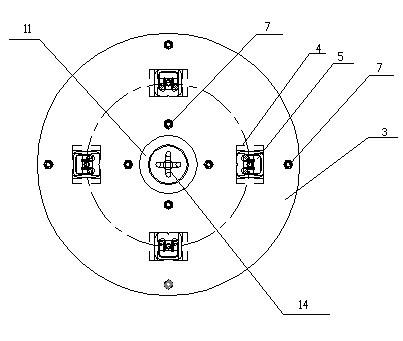

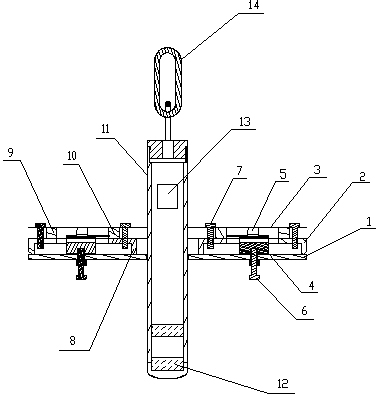

[0011] The anti-buried tilt switch can be hung on the lower end of the lifting integrated monitoring mechanism. The lifting integrated monitoring mechanism is installed on the top of the storage silo. With the reciprocating movement of the lifting mechanism, the storage height is monitored. When it reaches the surface of the storage material, the cylinder will tilt. At this time, the mercury switch is in a closed state, and a switch signal will be sent to the circuit board in the cylinder. The circuit board will send the processed signal to the control part of the lifting comprehensive monitoring mechanism. , calculate the descending distance of the anti-buried tilt switch, and thus calculate the storage height of the silo; when the anti-buried tilt switch moves to the surface of the storage material, it is hit by the blanking material, and the blanking material accumulates on the cover plate, and the cover plate It will produce deformation and transmit the pressure to the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com