Lamp housing heat dissipation structure and lamp

A technology of heat dissipation structure and lamp housing, applied in the field of lighting, can solve the problems of increasing the size of lamps, shortening the life of electrical devices, and increasing the temperature of electrical devices, and achieves the effects of small size, improved heat dissipation performance, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

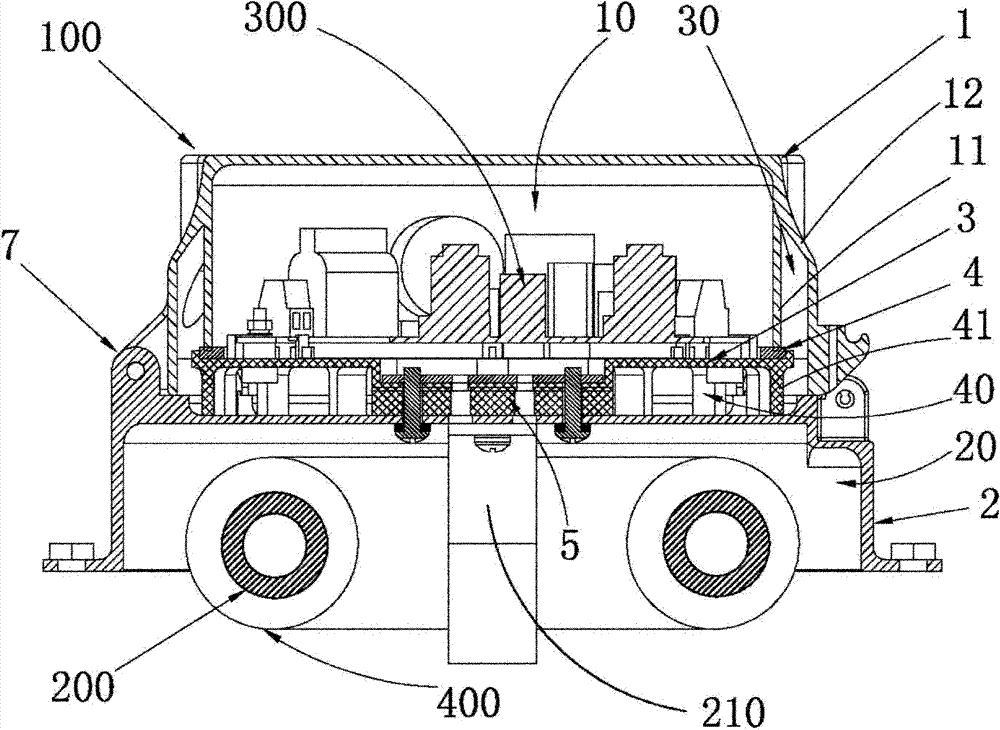

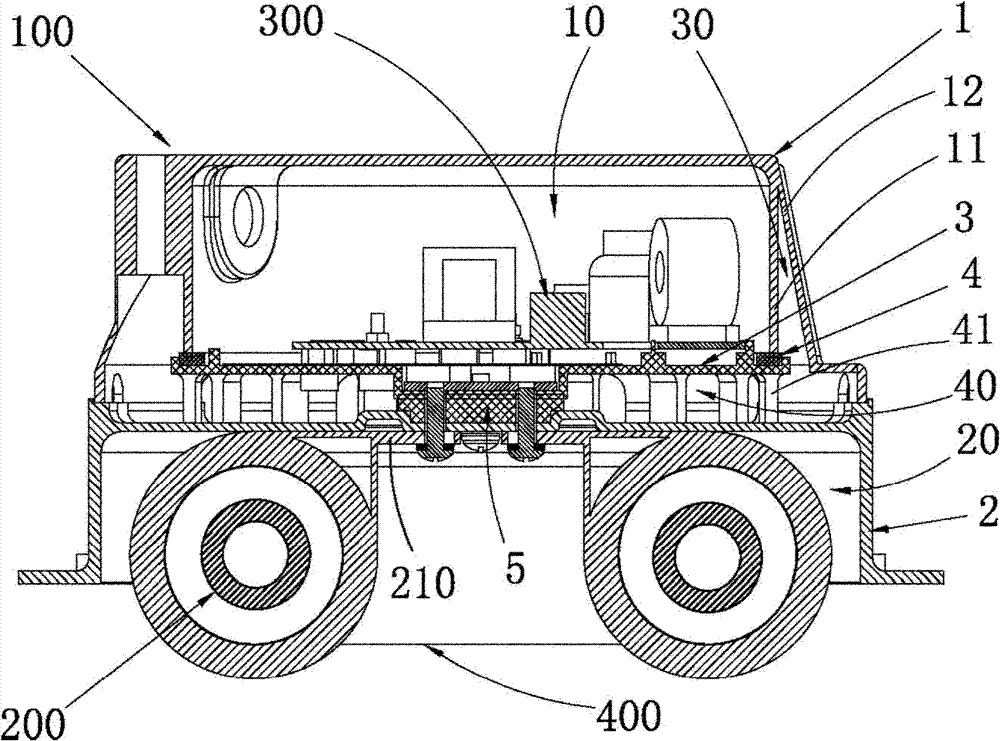

[0025] Further, see figure 1 and figure 2 , as an embodiment of the heat dissipation structure of the lamp housing provided by the present invention, the electrical appliance fixing plate 3 is connected to the lower casing 2, and the second sealing member 5 is arranged on the electrical appliance fixing plate 3 and the electrical appliance fixing plate 3 The connection of the lower case 2. The electrical appliance fixing plate 3 can also be connected with the upper casing 1, but it is not as convenient as connecting with the lower casing 2. At the same time, the electrical appliance fixing plate 3 is connected with the lower casing 2. When the upper casing 1 is opened, it is located on the electrical appliance fixing The electrical components on the board 3 are directly exposed outside, which is beneficial to the maintenance of the electrical components. Since the connection between the electrical appliance fixing plate 3 and the lower housing 2 uses bolts, there will be a ...

specific Embodiment approach

[0033] Further, see figure 2 , as a specific embodiment of the lamp provided by the present invention, a light source fixing seat 210 is arranged inside the lower casing 2, and the light source fixing seat 210 is assembled in direct contact with the lower casing 2 in a large area. The light source component 200 is disposed on the light source fixing seat 210 . In this way, the heat generated by the light source part 200 can be transferred to the light source fixing seat 210 through the most effective heat conduction method, and then transferred to the lower casing 2 and dissipated, so that the heat dissipation efficiency is improved.

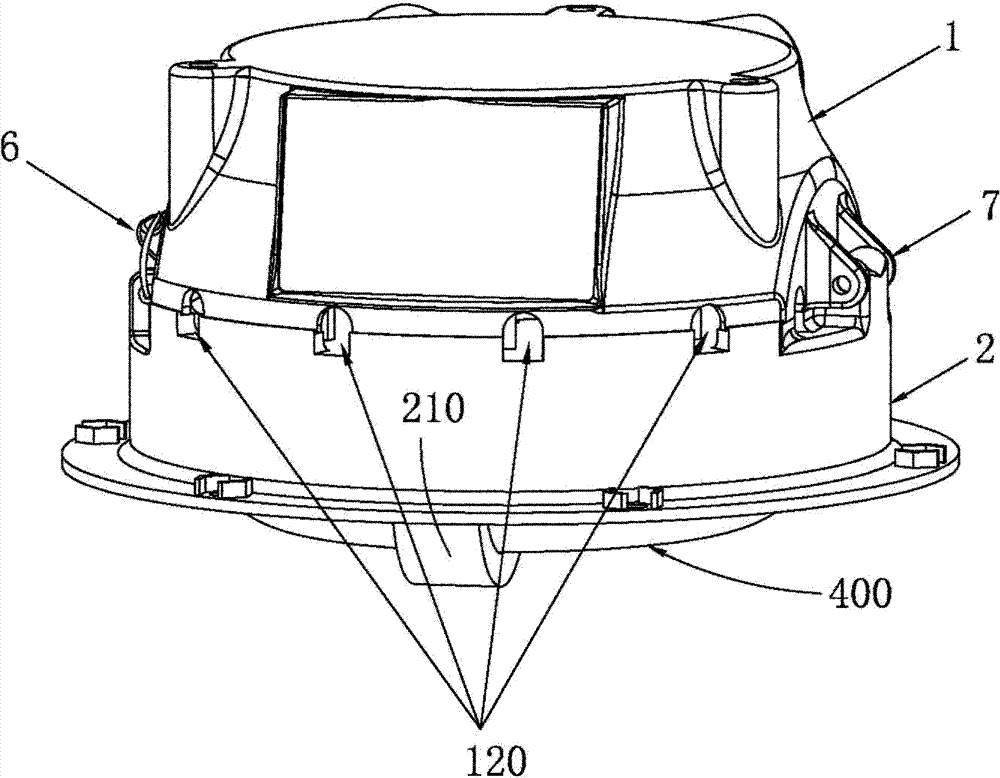

[0034] Further, see figure 1 and image 3 , as a specific embodiment of the lamp provided by the present invention, a transparent casing 400 for protecting the light source part 200 is also provided on the periphery 200 of the light source part. The transparent casing 400 can prevent foreign objects from directly contacting the light source ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com