a sleeve valve

A technology of sleeve valve and outer cylinder, which is applied in the direction of valve device, engine seal, engine components, etc. It can solve the problems of easy outflow and inability to effectively realize two-way sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

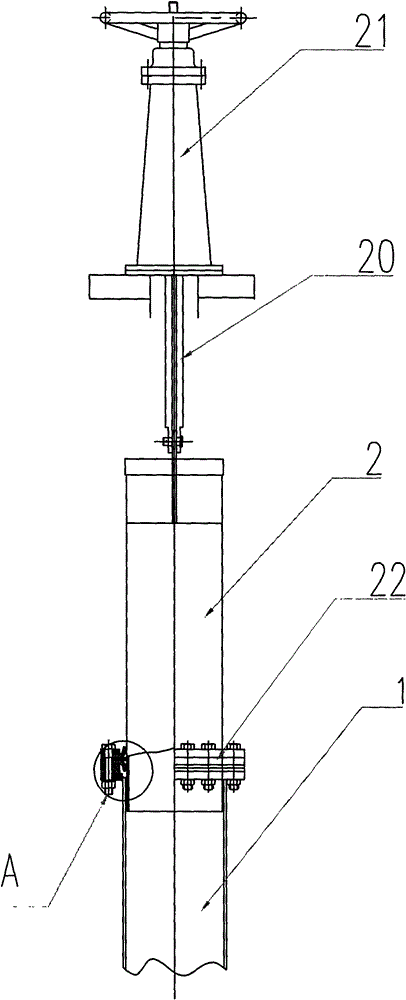

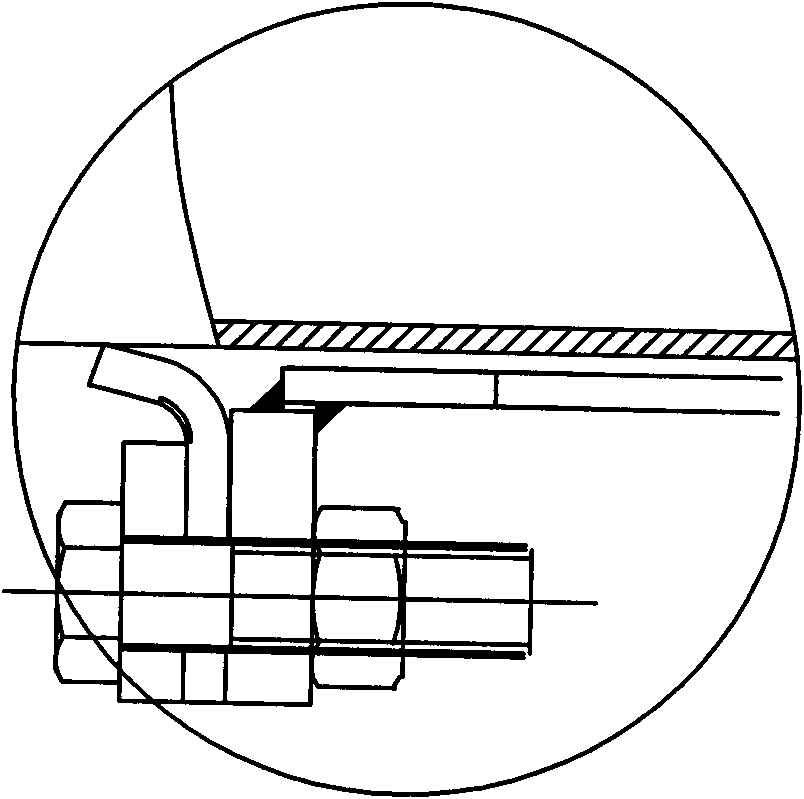

[0014] like figure 1 , figure 2 As shown in the structural diagram of the sleeve valve of the present invention, the sleeve valve of the present invention comprises an outer cylinder 1, an adjusting cylinder 2, a screw rod 20 and a hoist 21, the outer diameter of the adjusting cylinder 2 is smaller than that of the outer cylinder 1, and the outer cylinder 1 Inserting the adjusting cylinder 2, under the drive of the hoist 21 and the screw rod 20, the adjusting cylinder 2 can move up and down relative to the outer cylinder 1. A sealing device 22 is provided on the upper end of the outer cylinder 1. The sealing device 22 includes a flange 3, a gasket 9, a lower sealing ring 8, a gasket 7, an upper sealing ring 4, a pressure plate 5 and a bolt 6. The inner diameter of the flange 3 is the same as that of the outer cylinder 1. The outer diameter of the flange is adapted and welded on the outer cylinder 1, and the bolt 6 connects the flange 3, the gasket 9, the lower sealing ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com