Rotary compressor

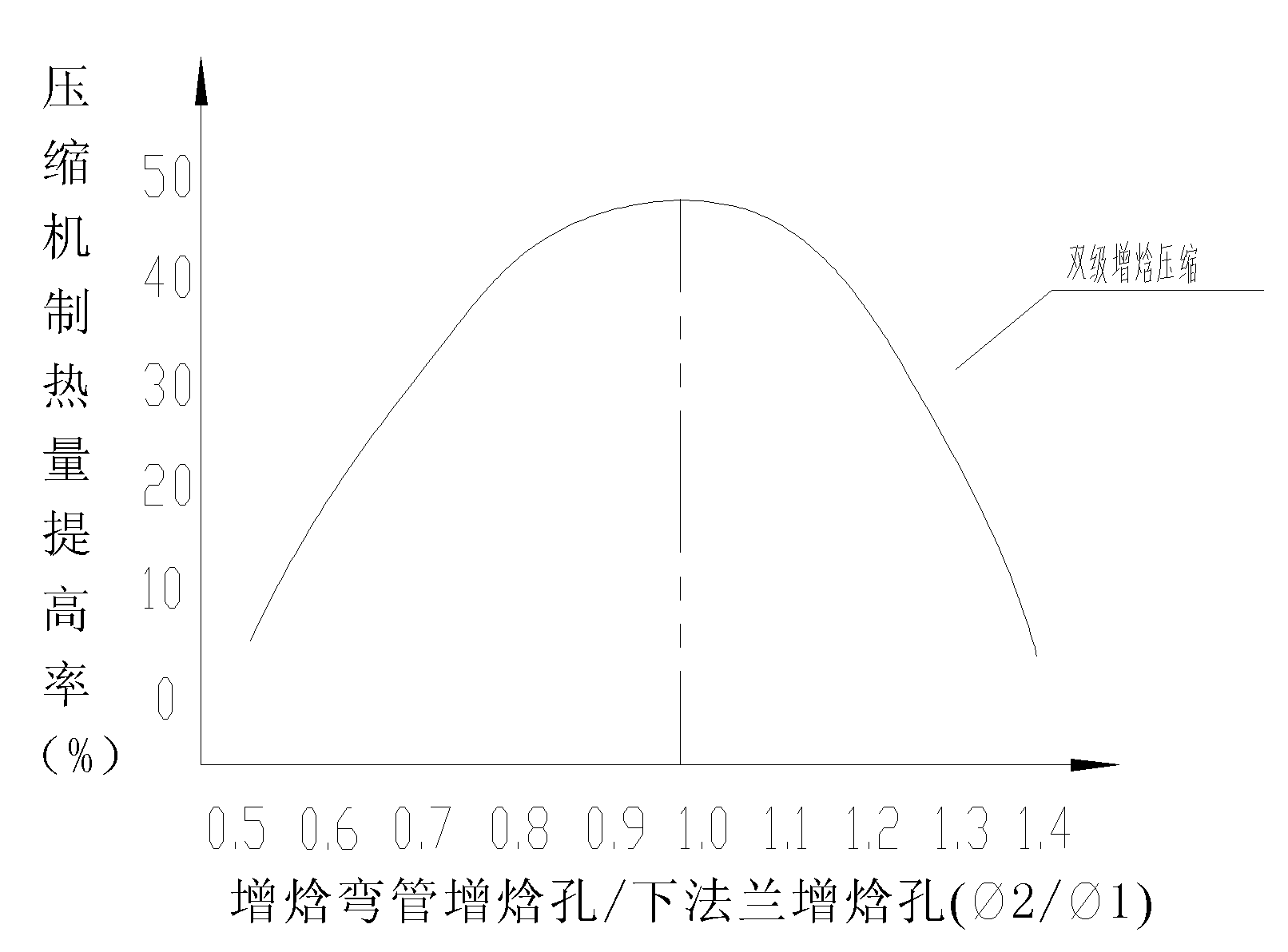

A rotary compressor and compressor technology, which is applied in the field of HVAC, can solve problems such as the decrease of the heating capacity of the compressor, the reduction of the unit suction capacity of the compressor, and the large suction-to-exhaust pressure ratio of the compressor, so as to reduce fluid leakage and friction Loss, increase heating and cooling capacity, increase the effect of unit suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings and in conjunction with embodiments. It should be noted that the embodiments in the present application and the features of the embodiments may be combined with each other in the case of no conflict.

[0030] The direction of the arrow in the figure represents the flow direction of the refrigerant.

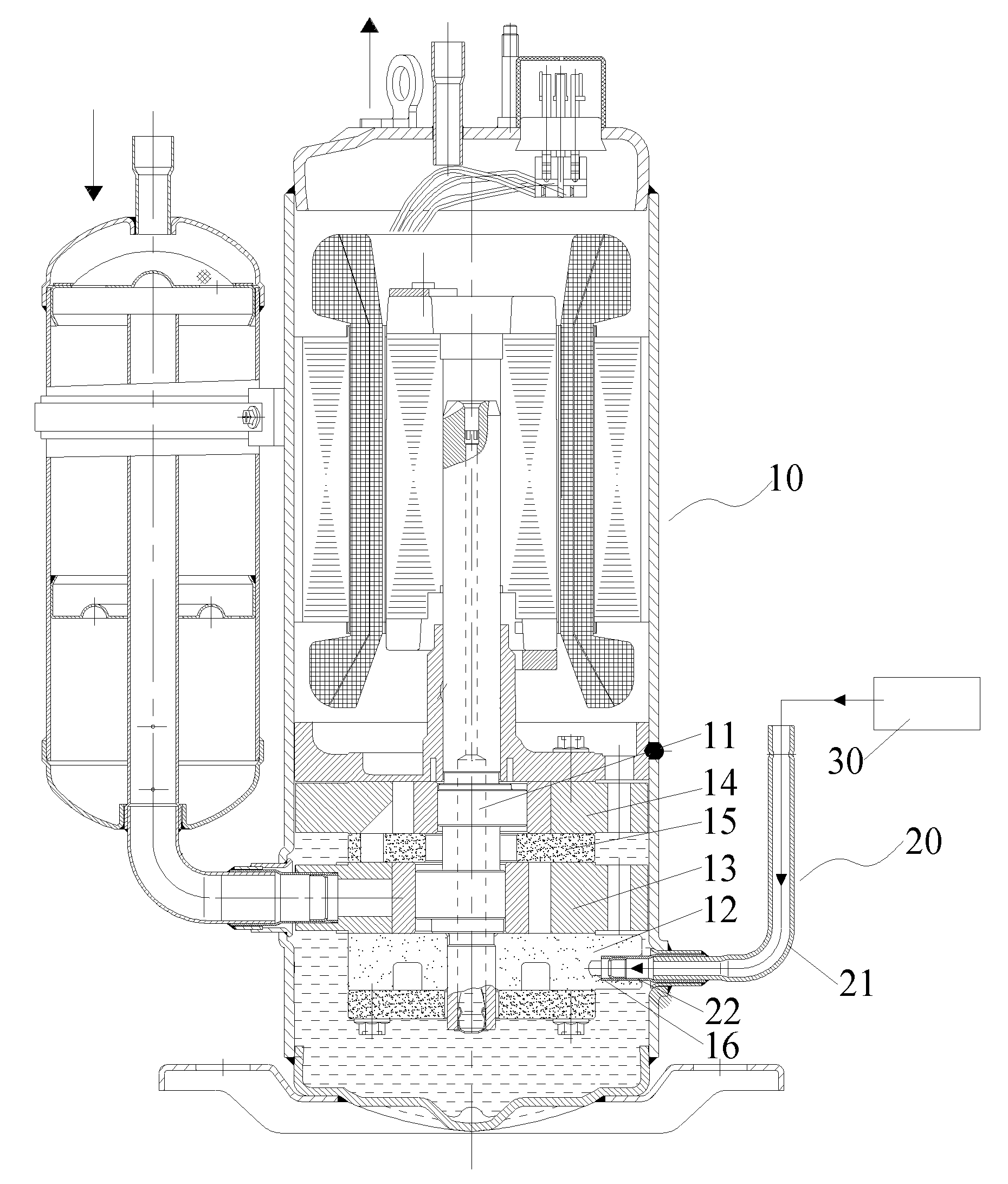

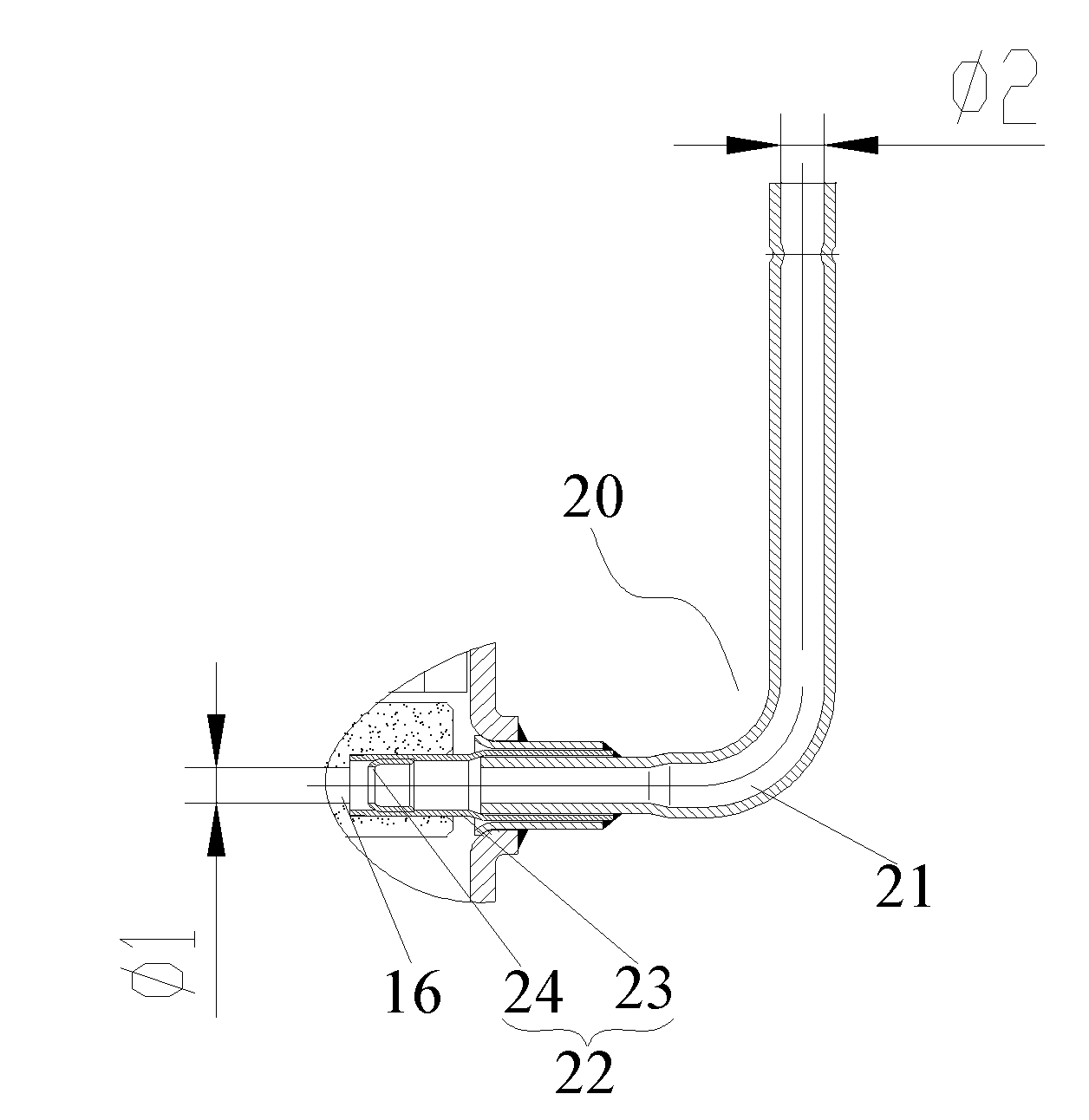

[0031] from figure 1 As can be seen in the embodiment of the present invention, the rotary compressor includes a compressor body 10 and an enthalpy tube assembly 20 connected to the compressor body 10, wherein the compressor body 10 includes a crankshaft 11; Flange 12; low pressure cylinder 13 matched with the crankshaft and arranged upstream of the lower flange 12; and high pressure cylinder 14 matched with the crankshaft and arranged upstream of the low pressure cylinder 13, and a The partition plate 15 separates the suction chamber and the compression chamber of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com