Package structure and packaging method of post insulators

A technology of packaging structure and packaging method, which is applied in the directions of transportation and packaging, packaging of vulnerable items, types of packaging items, etc., can solve the problems of damaged insulators, unstable fixed insulators, bumps of insulator sheds, etc., so as to prevent bumps and save packaging. material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

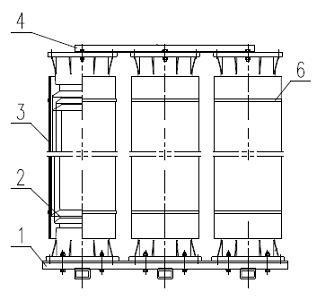

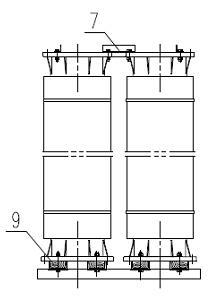

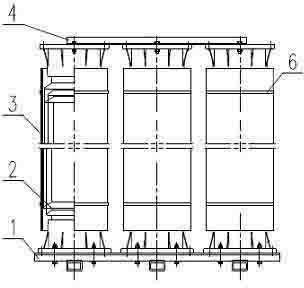

[0024] An embodiment of a packing structure of a post insulator, such as figure 1 , 2 As shown, it includes insulators 2 with upper and lower flanges arranged vertically and horizontally and vertically. Above the insulator 2, there is a top connecting piece that connects the upper flanges of the insulator together. The top connecting piece corresponds to the upper flange. The upper flange hole of the flange is provided with a top connector hole, and the bolt is penetrated into the upper flange hole and the top connector hole, and the top connector is tightly connected to the upper flange by the nut screwed on the bolt. The top connecting piece includes a horizontal connecting piece 4 connecting the upper flanges of the insulators arranged in parallel in the horizontal direction and a vertical connecting piece 7 connecting the upper flanges of the insulators arranged in parallel in the longitudinal direction. The bottom connecting piece 1 is connected together with the lower f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com