Lifting core-pulling device with angle-lift core block

A core-pulling device and oblique sliding technology are applied in the field of slanted top core-pulling and demolding mechanisms of injection molds, which can solve the problems of low pass rate, waste products, and damage to the rib structure, so as to improve the pass rate, reduce costs, and avoid damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

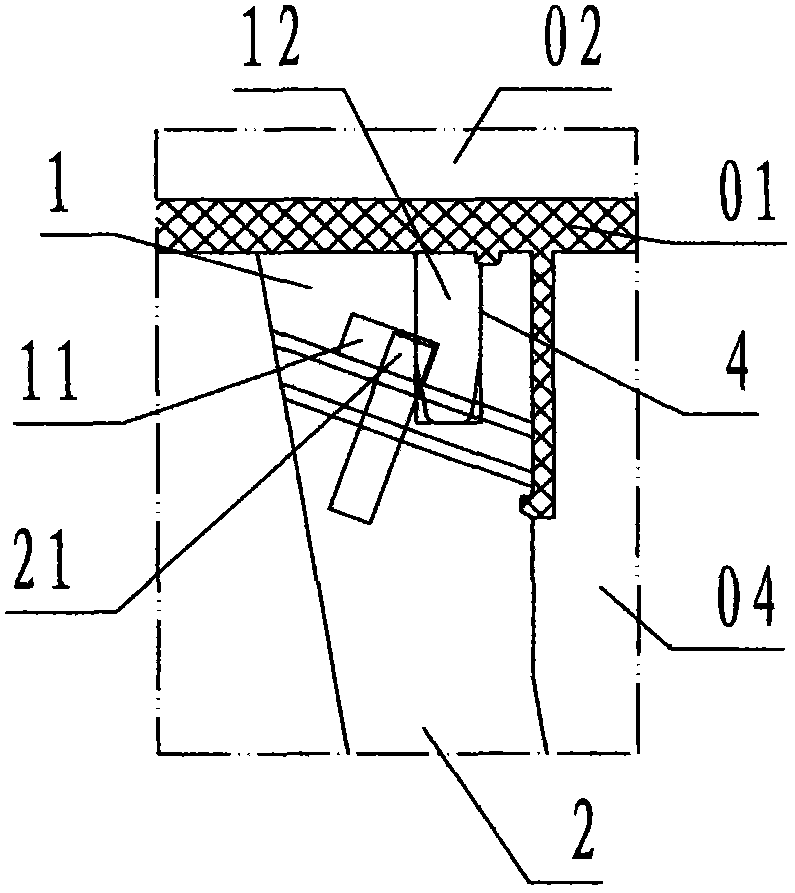

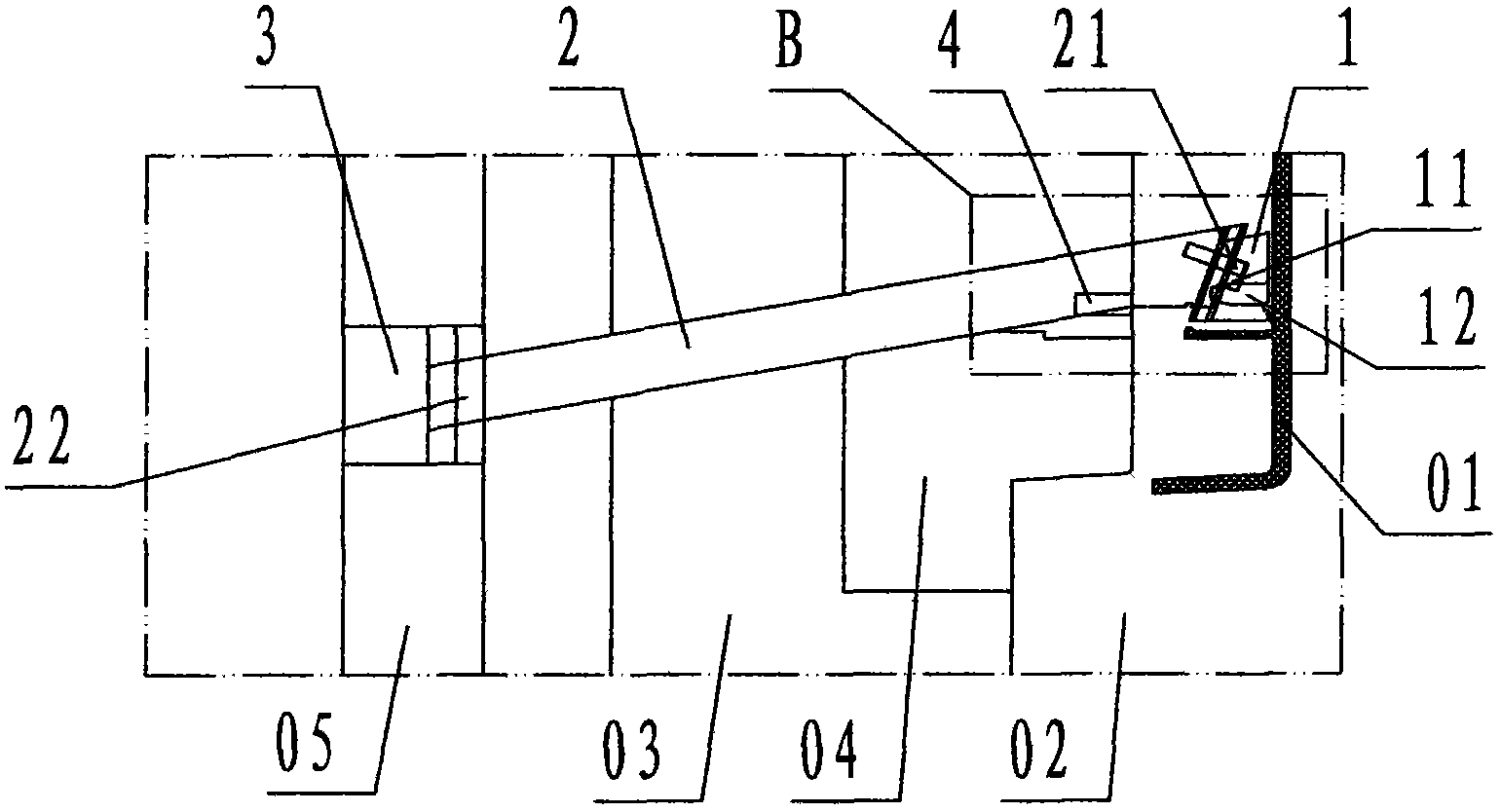

[0024] refer to Figure 1 ~ Figure 4 , a kind of inclined top core-pulling device that is provided with inclined sliding core block of the present invention, comprises inclined sliding core block 1, inclined ejector rod 2, ejector rod sliding seat 3, reset chute 4, wherein: described inclined sliding core Block 1 is a steel slider with longitudinal ribs embedded in the product and a horizontal undercut structure; the bottom of the oblique sliding core block 1 is a slope that slopes downward from left to right, and is provided with a T parallel to the slope. Shaped inclined chute; the middle part of the bottom of the inclined chute is provided with an oblong groove, which is called the limit chute 11; , a protruding reset button 12 with a rectangular cross-section, the lower part of the reset button 12 is provided with a wedge-shaped transition end;

[0025] The inclined ejector rod 2 is a rectangular rod-shaped steel member; the top of the inclined ejector rod 2 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com