Chemical mechanical polishing method

A chemical-mechanical and polishing layer technology, applied in the direction of grinding machine tools, grinding devices, electrical components, etc., can solve the problem that residues are difficult to remove, cannot effectively solve the problems of yield and long-term stability of semiconductor devices, and affect the yield and long-term stability of semiconductor devices. Long-term stability and other issues, to achieve the effect of high yield, high flatness and good long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

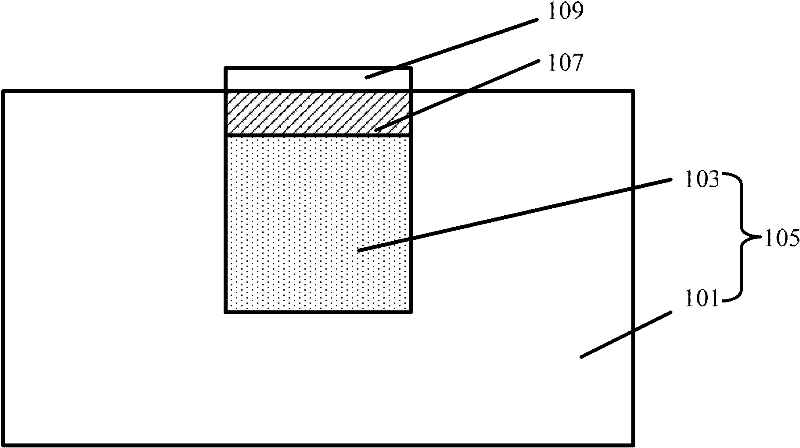

Image

Examples

Embodiment Construction

[0029] It can be seen from the background technology that the existing chemical mechanical polishing method is difficult to remove the metal oxides and hydroxides on the surface of the polishing layer, and the corrosion inhibitors attached to the surface of the metal oxides and hydroxides, resulting in the surface of the polishing layer The flatness is low, the yield rate of the final semiconductor device is low, and the long-term stability is poor.

[0030] The inventors of the present invention have studied the above problems. In the prior art, BTA is added in the grinding process, and the BTA will be attached to the surface of the oxide and / or hydroxide of the metal, which is difficult to remove, and it is ground with an acidic grinding slurry The polishing layer is easy to corrode the surface of the polishing layer, resulting in low flatness of the surface of the polishing layer.

[0031] The inventors of the embodiments of the present invention have found through further ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com