Tandem type full-automatic multiple-head hoop bending machine

A fully automatic, series-type technology, applied in the field of building materials machinery, can solve the problems of manual removal of materials, lower production efficiency, and potential safety hazards, and achieve high production efficiency, fewer safety hazards, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

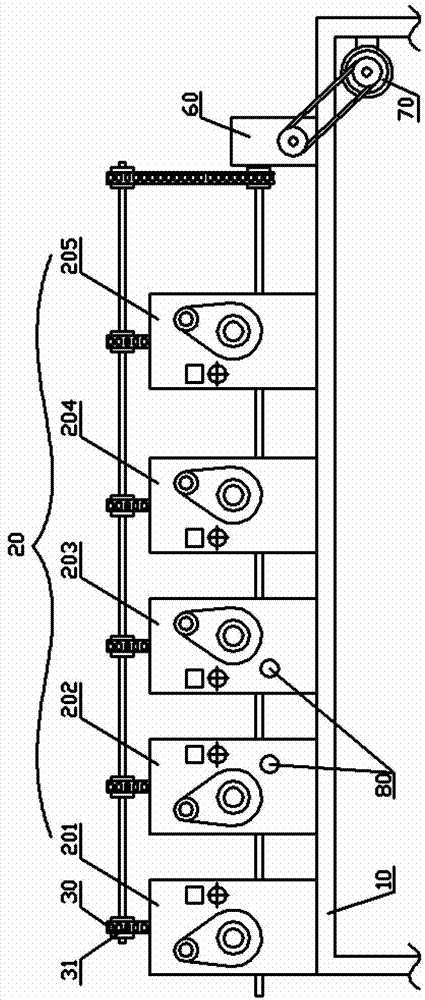

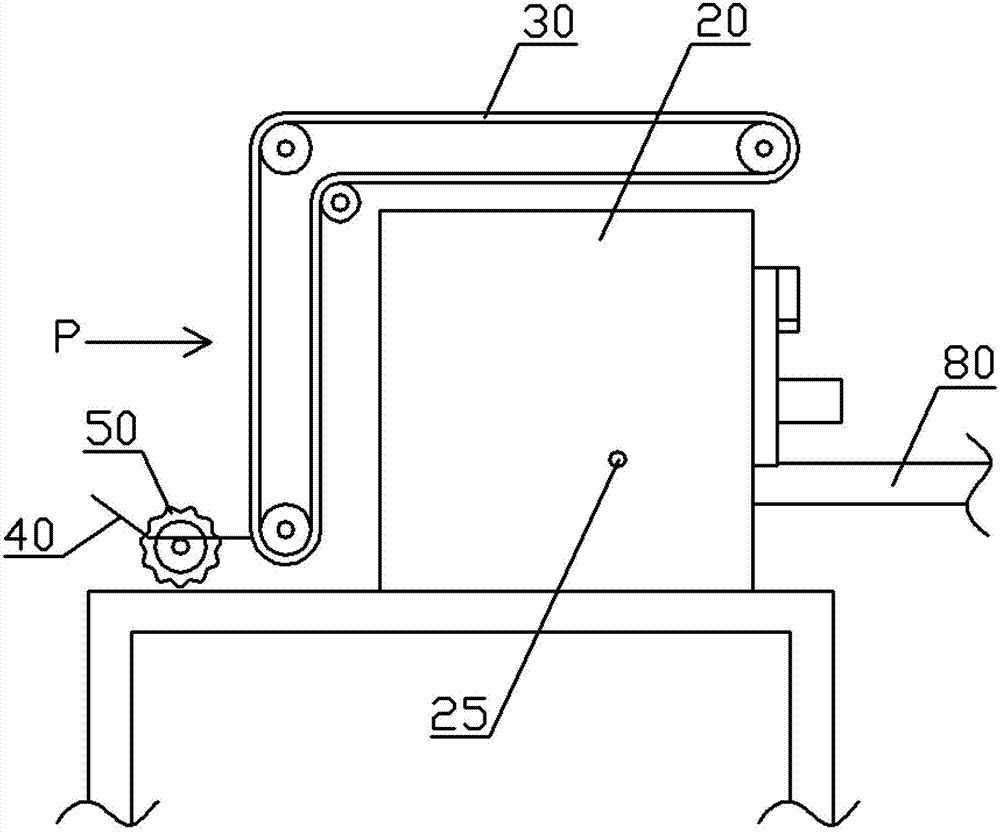

[0022] Examples, see Figure 1 to Figure 4 Shown: tandem automatic multi-head hoop bending machine, including frame 10. Machine head 20, speed reducer 60 and motor 70 are fixed on frame 10. Obviously, the reducer 60 is connected to the motor 70 . Wherein, the machine head 20 is a first machine head 201 , a second machine head 202 , a third machine head 203 , a fourth machine head 204 and a fifth machine head 205 arranged in a row. Simultaneously, each machine head 20 all has a front plate 26, and the front plate 26 is provided with a telescopic shaft 21, a clamping shaft 24 and an eccentric block 22, and the eccentric block 22 is provided with a bending hoop wheel 221.

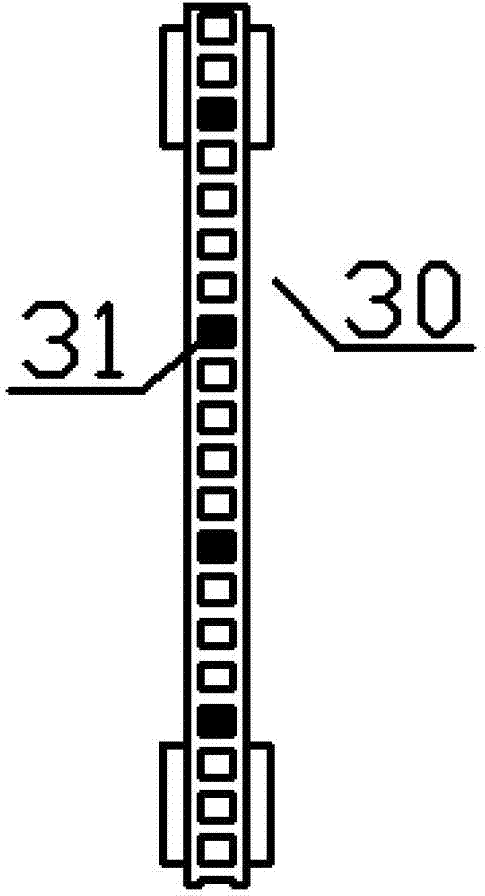

[0023] The tandem automatic multi-head hoop bending machine includes a conveying chain 30 on which a conveying magnet 31 is arranged, and the conveying chain 30 is connected to a reducer 60 . That is, the speed reducer 60 drives the conveyor chain 30 to rotate, and the conveyor magnet 31 can absorb raw mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com