Fixed spray flue gas purifying device

A flue gas purification, intermediate flue technology, applied in chemical instruments and methods, dispersed particle filtration, dispersed particle separation, etc., can solve the problems of absorbent and by-product adhesion, slow reaction temperature control, high investment cost, and achieve cost Low, prevent excessive acid emission, high finish effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

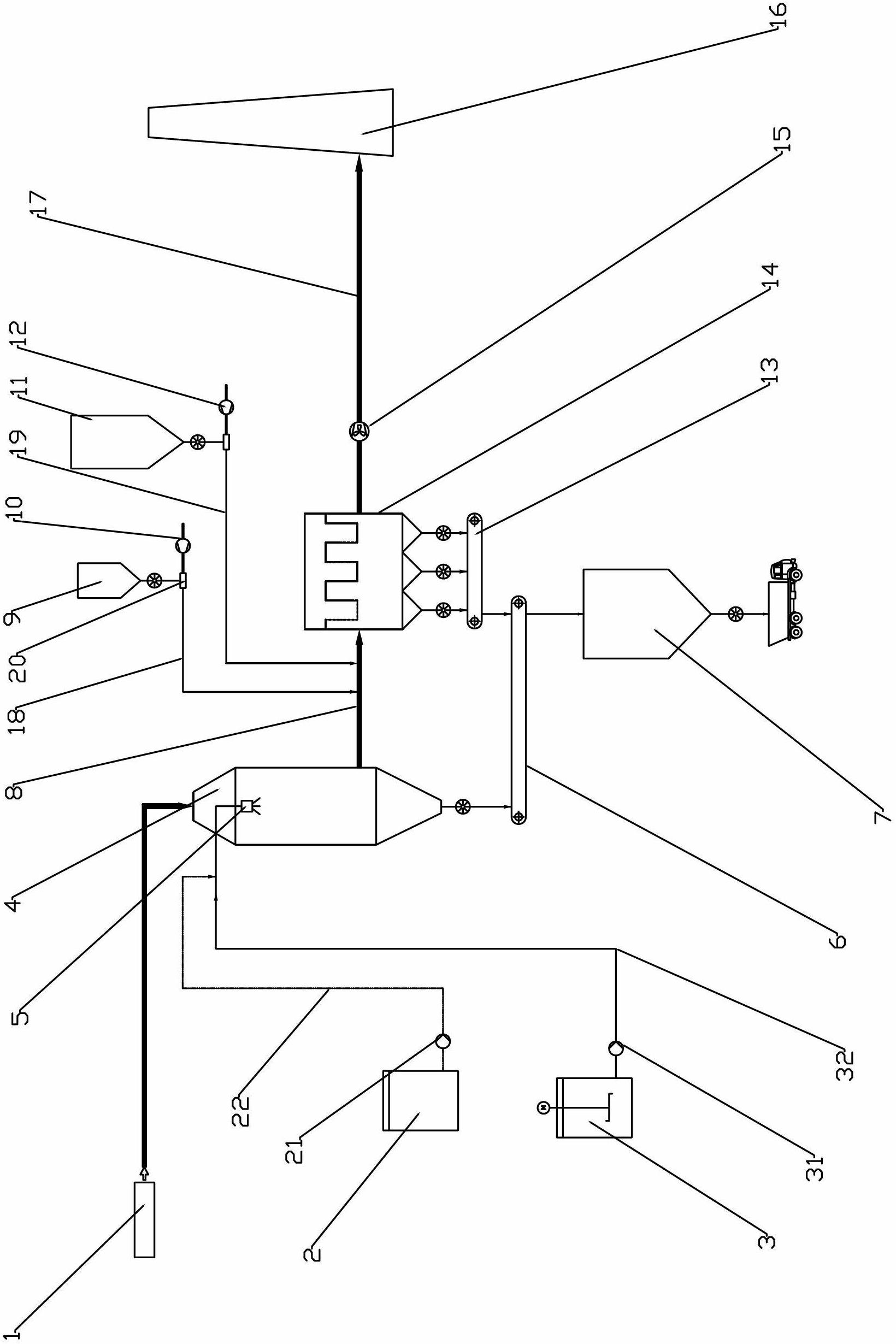

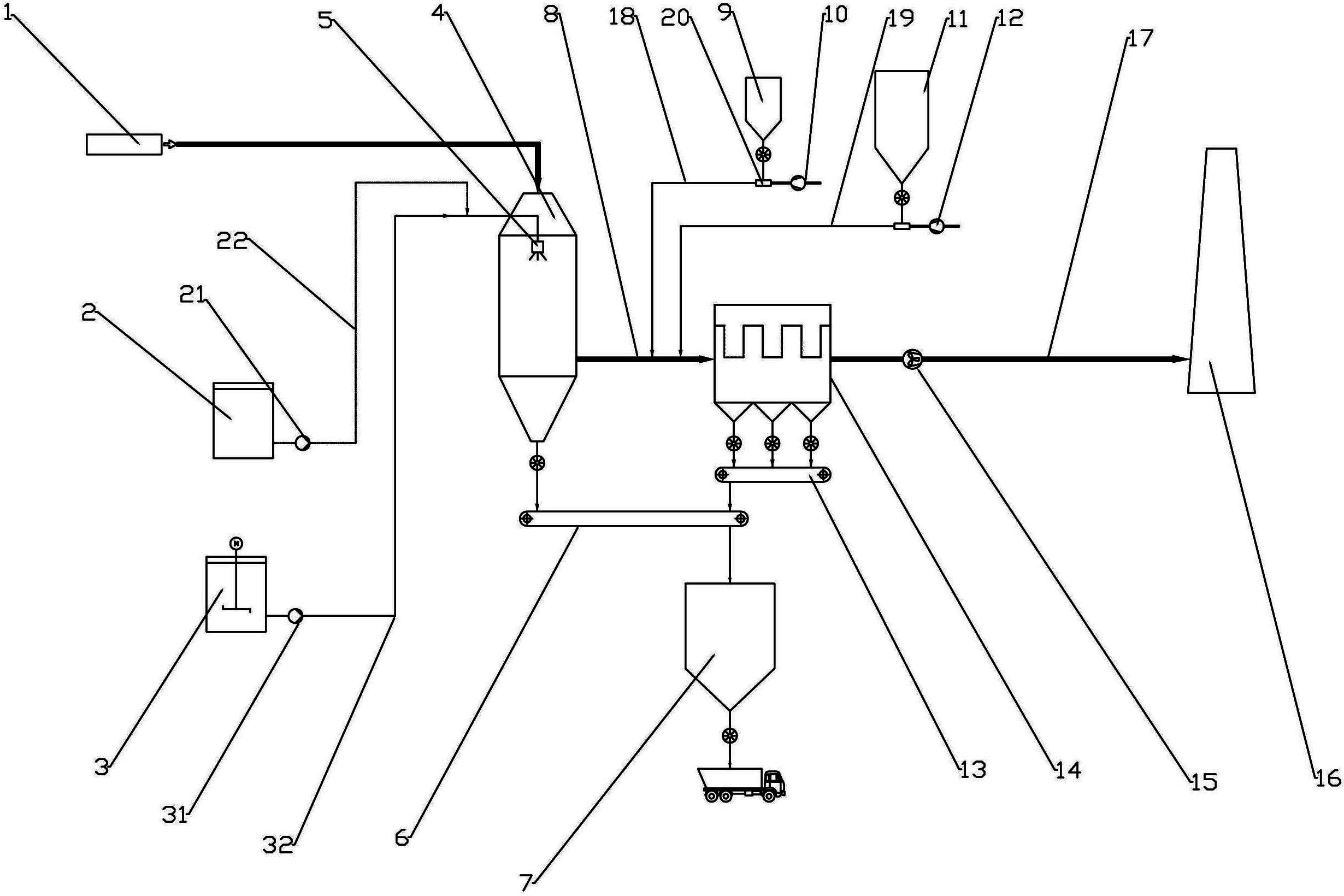

[0018] Such as figure 1 As shown, the present invention mainly includes a water tank 2, a first pipeline 22, a deacidification raw material tank 3, a semi-dry reaction tower 4, a fixed spray gun 5, a first fly ash conveyor 6, an ash storage bin 7, an intermediate flue 8, Activated carbon storage bin 9, first conveying fan 10, Ca(OH) 2 Dry powder storage bin 11, second conveying fan 12, second fly ash conveyor 13, bag filter 14, induced draft fan 15, chimney 16, end flue 17, third pipeline 18, fourth pipeline 19 and activated carbon metering feed Material device 20.

[0019] The water tank 2 is connected to the semi-dry reaction tower 4 through the first pipeline 22, the first pipeline 22 is provided with a water tank pump 21, and industrial water is stored in the water tank 2, and the industrial water is pumped into the semi-dry reaction tower 4 by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com