Apparatus and method for producing round brushes

A kind of equipment and technology of round brushes, applied in the field of manufacturing round brushes, to achieve the effect of improving process safety and improving pull-out force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

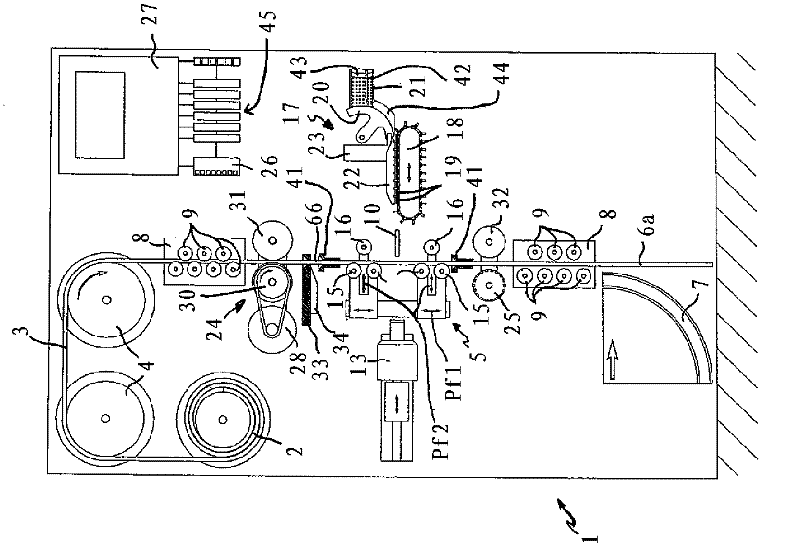

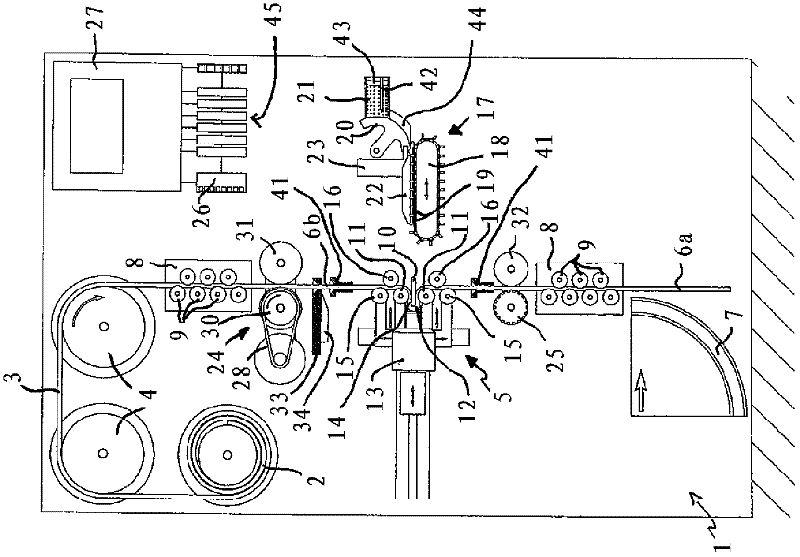

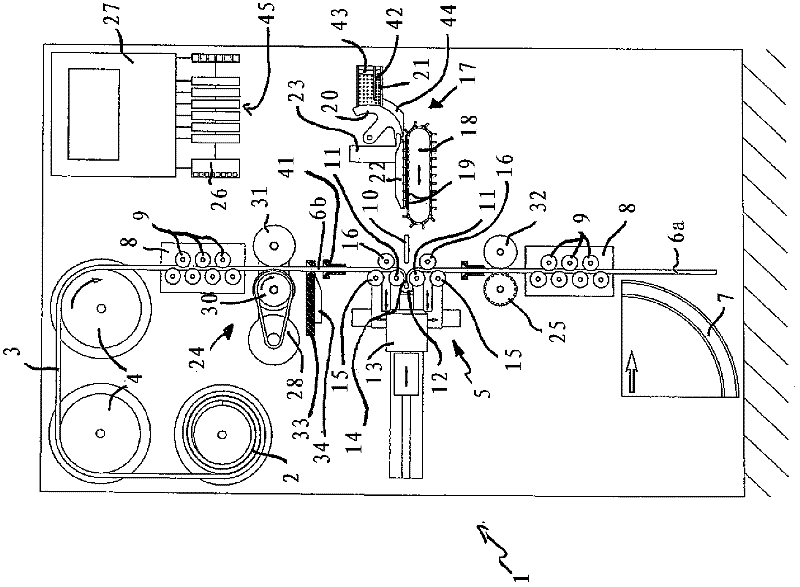

[0067] according to figure 1 , a device for the manufacture of round brushes 37 , designated as a whole by 1, has a wire spool 2 with a wire 3 which is unwound from the wire spool 2 and brought via two deflection rollers 4 to In the area of the steering gear 5. The wire 3 is first unwound so far that the free end of the wire 3 is positioned as a wire section 6 a past the deflection device 5 . A wire section 6 a , 6 b of the unwound wire 3 is therefore located above and below the deflection device 5 . The wire section 6a forming the free end of the wire 3 is approximately as long or slightly longer than the round brush 37 to be produced in order to compensate for the shortening in the main longitudinal direction during screwing. When the free wire section 6a is longer than the available space, the wire 3 can be guided through a deflection unit 7 which is formed as a hollow guide in the shape of a circular sector in the figure and bent thereby, so that the wire 3 can Unwind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com