Mounting device

A technology of mounting and mounting body, which is applied in the direction of lighting and heating equipment, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problems of space saving and other problems, and achieve space saving, cost reduction and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

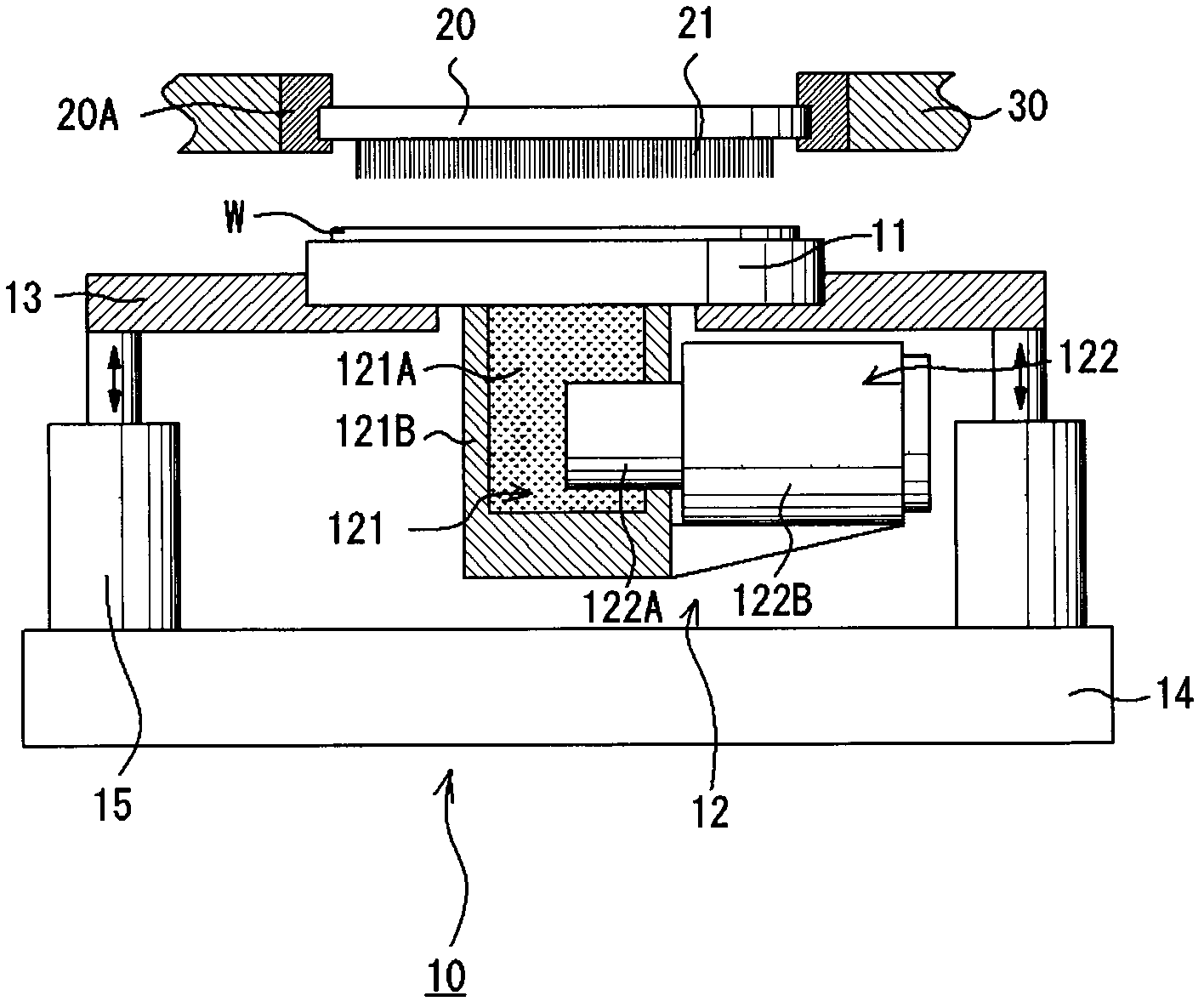

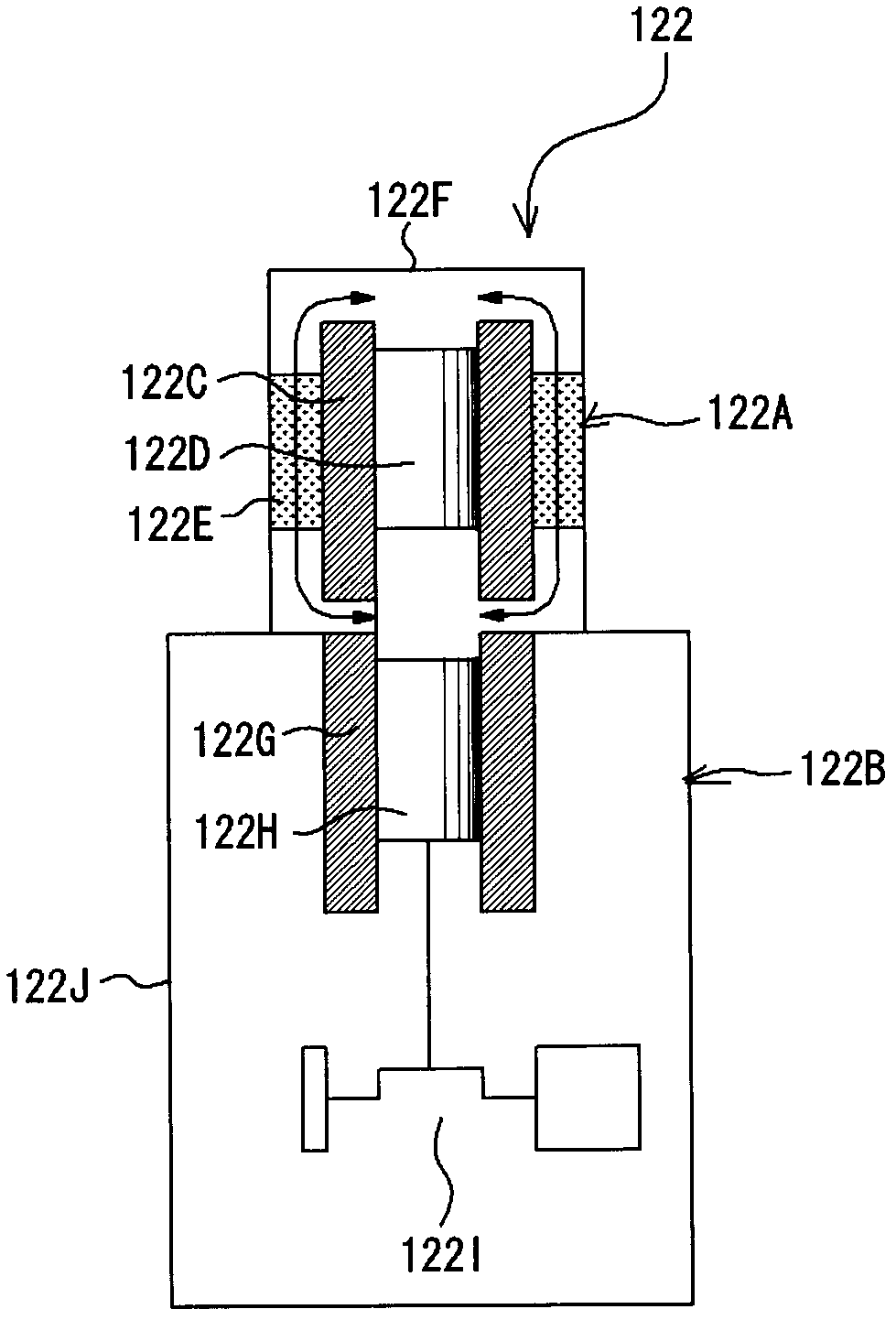

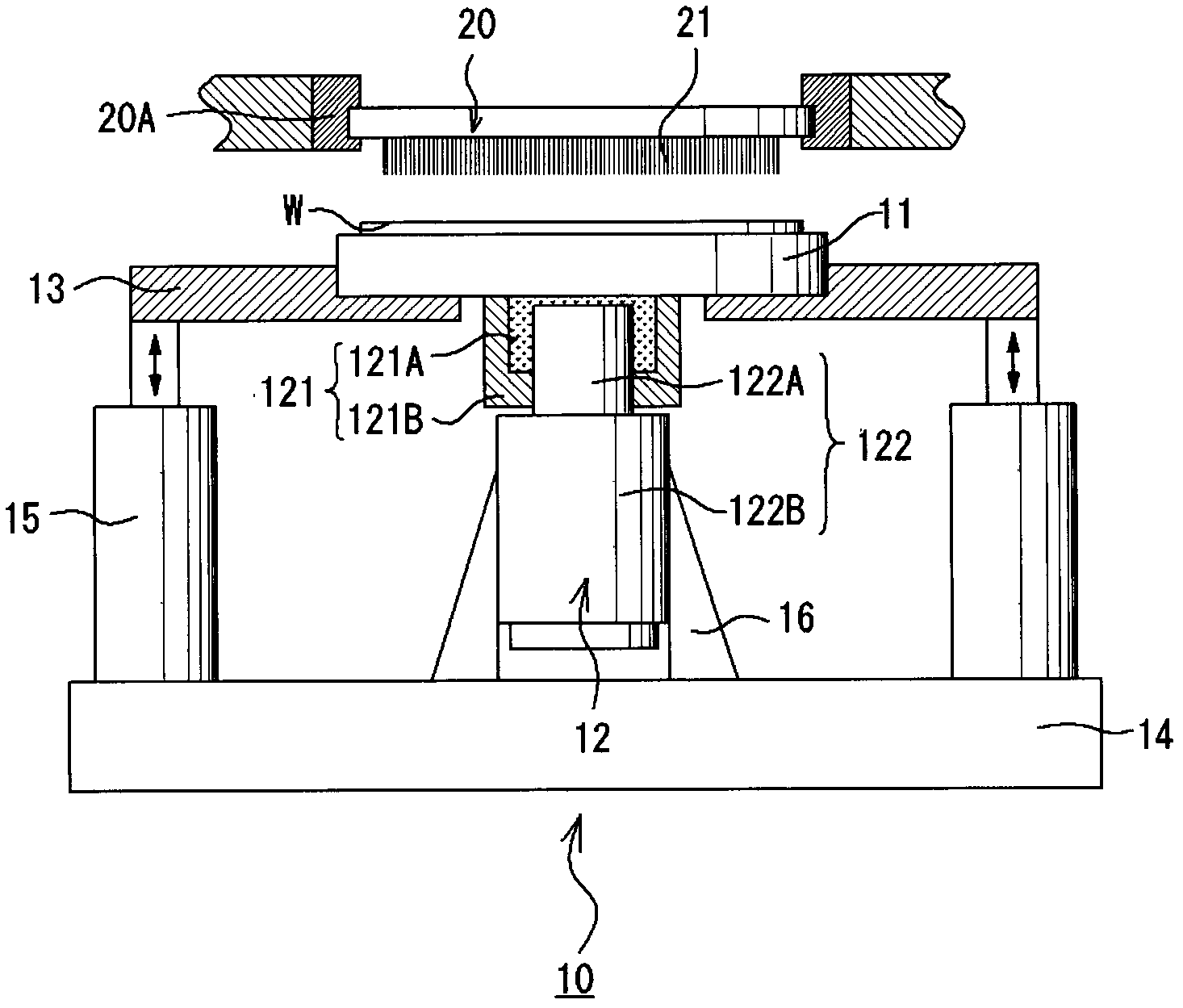

[0023] Below, based on Figure 1 ~ Figure 3 The illustrated embodiments illustrate the invention.

[0024] For example figure 1 As shown, the mounting device 10 of this embodiment includes: a mounting body (wafer chuck) 11 for mounting a semiconductor wafer W; a cooling mechanism 12 for cooling the semiconductor wafer through the wafer chuck 11 W; the support body 13, which supports the wafer chuck 11 at the outer peripheral edge of the wafer chuck 11; and the lifting mechanism 15, which supports the support body 13 at multiple positions in a manner that the support body 13 can be raised and lowered on the base 14 , the mounting device 10 is configured to be applied to, for example, an inspection device for inspecting electrical characteristics of a semiconductor wafer W. The above-mentioned lifting mechanism 15 may be constituted by a cylinder mechanism.

[0025] A probe card 20 is provided above the wafer chuck 11 . The probe card 20 is mounted on a top plate 30 forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com