Novel phase shifting rectifier transformer

A technology of rectifying transformers and phase shifting, applied in transformers, fixed transformers, variable transformers, etc., can solve the problems of complex structure of oil tanks and lead wires, selection of phase shifting angles, and high difficulty in implementation, so as to achieve low implementation difficulty, reduce equipment manufacturing, and Guarantee the effect of product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

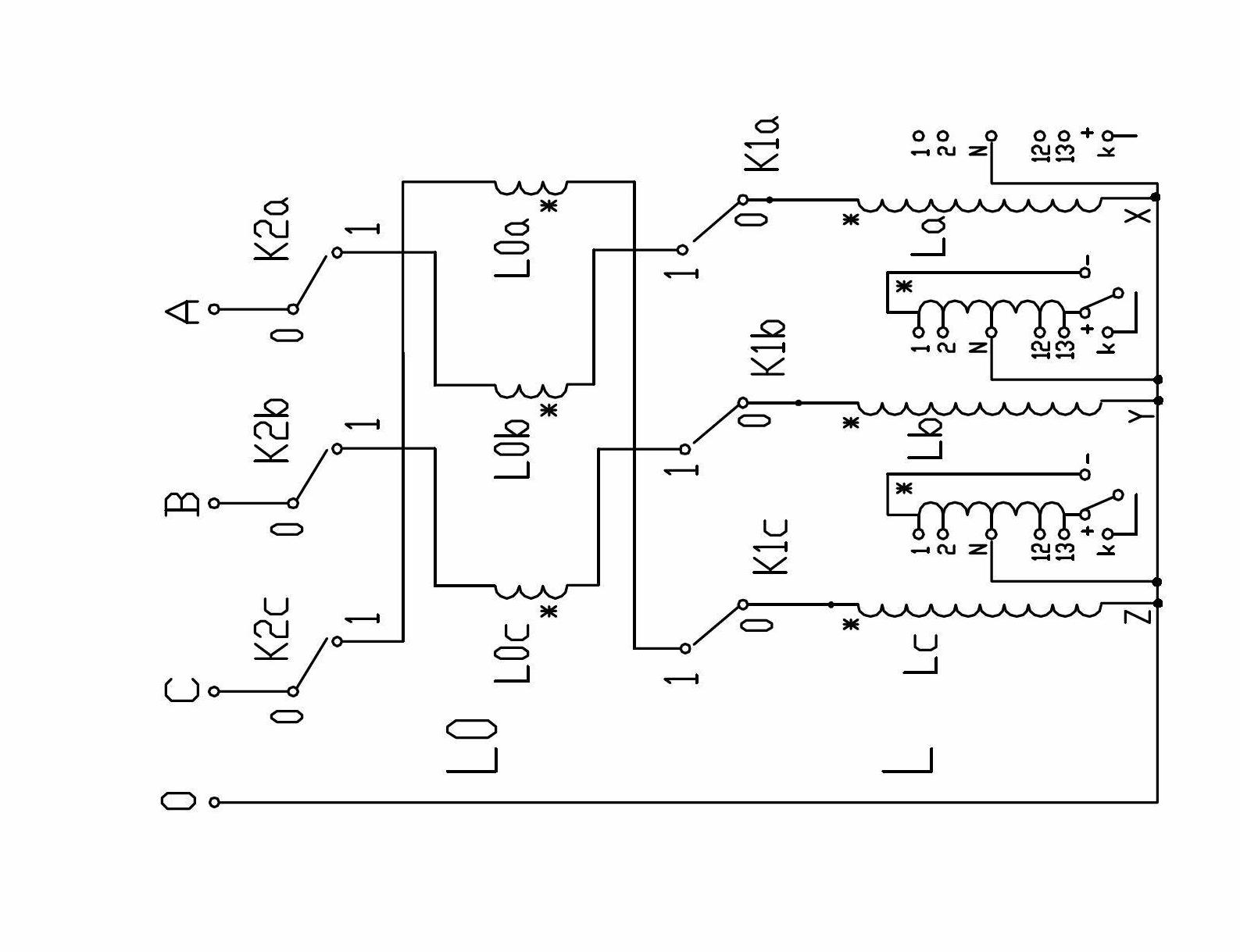

Image

Examples

Embodiment 1

[0032] Design requirements: The entire rectifier unit has two voltage-regulating rectifier transformers, model ZHSSPT-20000 / 63, requiring two voltage-regulating rectifier transformers to operate in parallel, with a single 12-pulse wave, and two sets of equivalent 24-pulse waves, and another one with the same The transformer of the model is used as a backup, and the design scheme is a one-to-two structure, that is, one voltage regulating and rectifying transformer includes a modulator body and two rectifier bodies, the modulating side adopts zigzag phase shifting, and the two modulating rectifiers The phase angles are +7.5° and -7.5° respectively; the primary side of the rectification adopts zigzag phase shifting, the phase shifting angles of the two rectifier bodies are respectively +15° and -15°, and the secondary rectification is triangular wiring. In this way, two voltage regulating rectifier transformers form an equivalent 24-pulse wave.

[0033] The scheme of the present...

Embodiment 2

[0044] Design requirements: The entire rectifier unit has three voltage-regulating rectifier transformers, model ZHSSPT-16000 / 35, and the user requires another transformer of the same type as a backup. These three voltage-regulating rectifier transformers operate in parallel. Composing equivalent 36 pulse waves, the design scheme is a one-to-two structure, that is, one voltage regulating rectifier transformer includes one modulator body and two rectifier bodies, the modulating side adopts zigzag phase shifting, and three modulating rectifiers The phase shift angles are +10°, 0° and -10° respectively; the primary side of the rectification adopts zigzag phase shift, and the phase shift angles of the two rectifier bodies are respectively +15° and -15°, and the rectification secondary The times are all triangle connections, so that the three voltage regulating rectifier transformers form an equivalent 36-pulse wave.

[0045] Scheme of the present invention: see attached Figure 4...

Embodiment 3

[0058] Design requirements: The entire rectifier unit has three voltage-regulating rectifier transformers, model ZHSSPT-25000 / 35, and the user requires that they be put into operation in two phases. In the first phase, two sets will be put into operation first, and the entire unit will form an equivalent 24-pulse wave; After running in parallel with the two units in the first phase, the whole unit constitutes an equivalent 36-pulse wave, and the design scheme is a one-to-two structure, that is, a voltage regulating rectifier transformer includes a regulator body and two rectifier bodies, and the modulation side Zigzag phase-shifting is adopted. The phase-shifting windings of the two modulators in the first phase are designed to have angle taps of +10°, +7.5°, 0°, -7.5° and -10°. Use no phase shift (that is, phase shift 0°).

[0059] The scheme of the present invention is: see attached Figure 8 , a new type of phase-shifting rectifier transformer, including a modulator body, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com