Wire-wound resistor with aluminum shell

A technology of wire-wound resistors and aluminum shells, which is applied in the directions of resistor installation/support, resistor shells/packaging shells/potting, spiral coils/spiral coil resistance elements, etc., which can solve the problems of unstable quality and performance of wire-wound resistors, Inconvenient installation and other problems, to achieve the effect of ensuring insulation, convenient processing, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

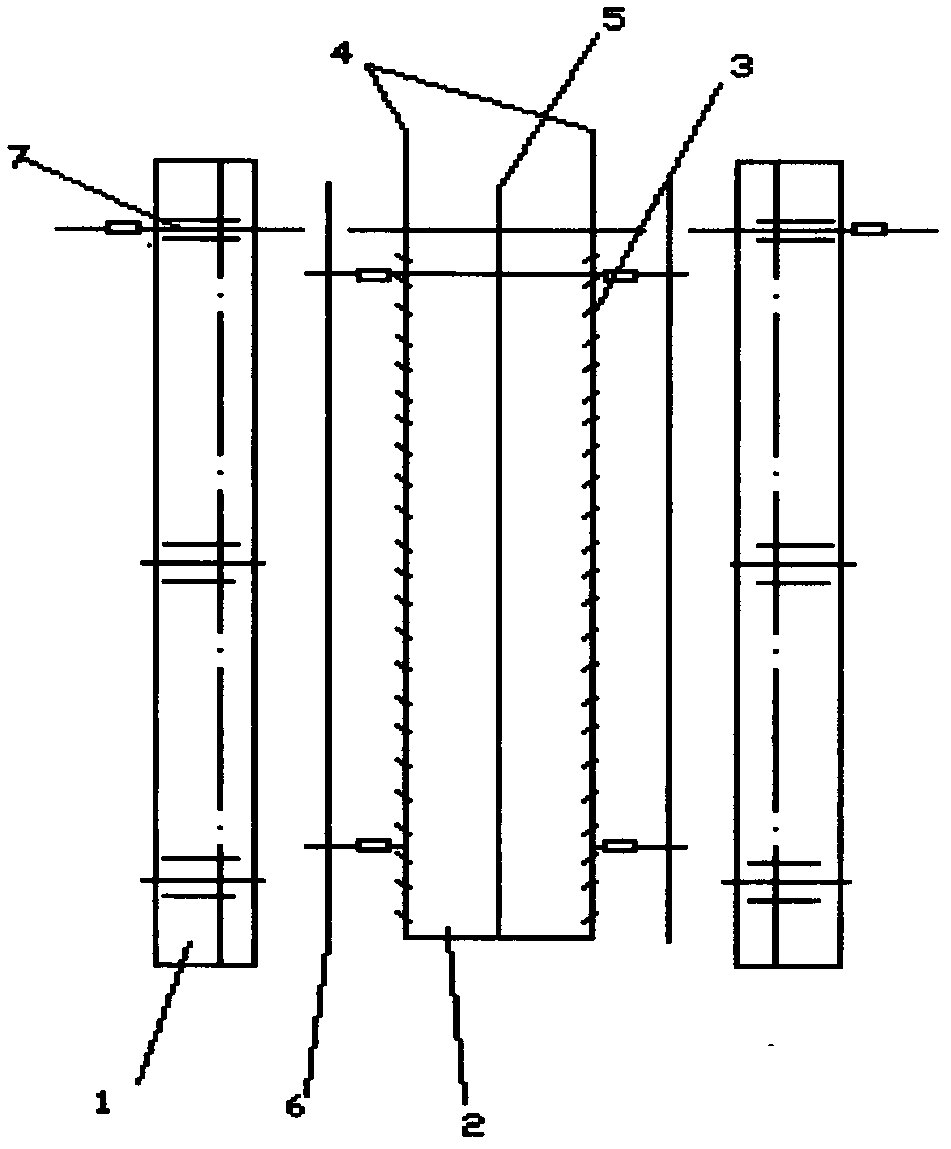

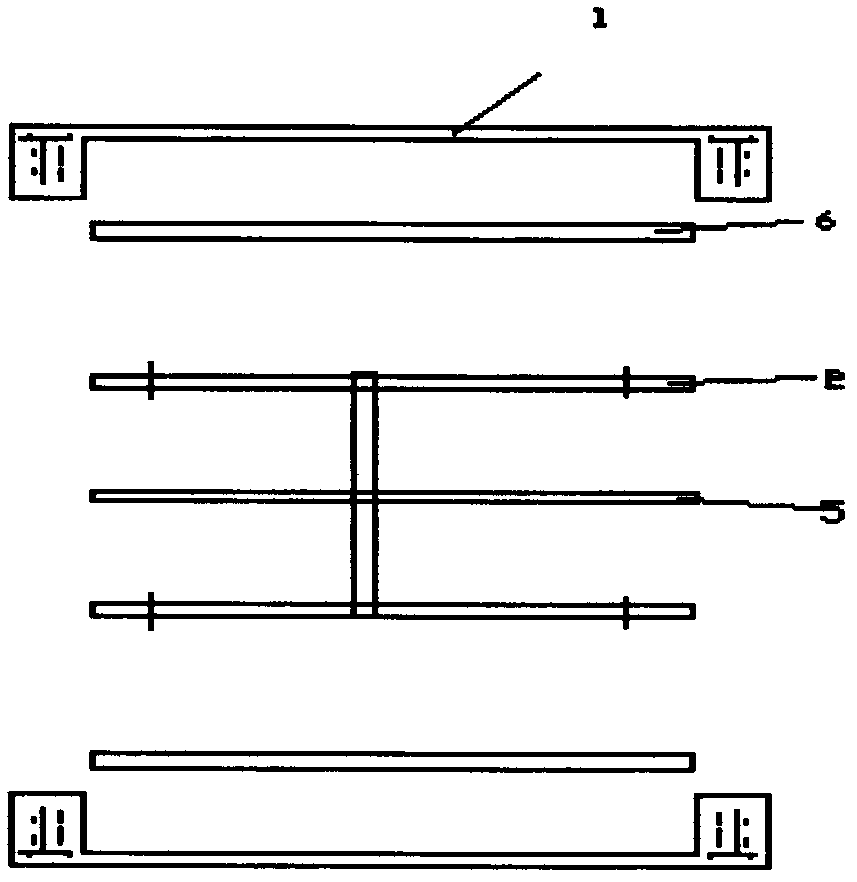

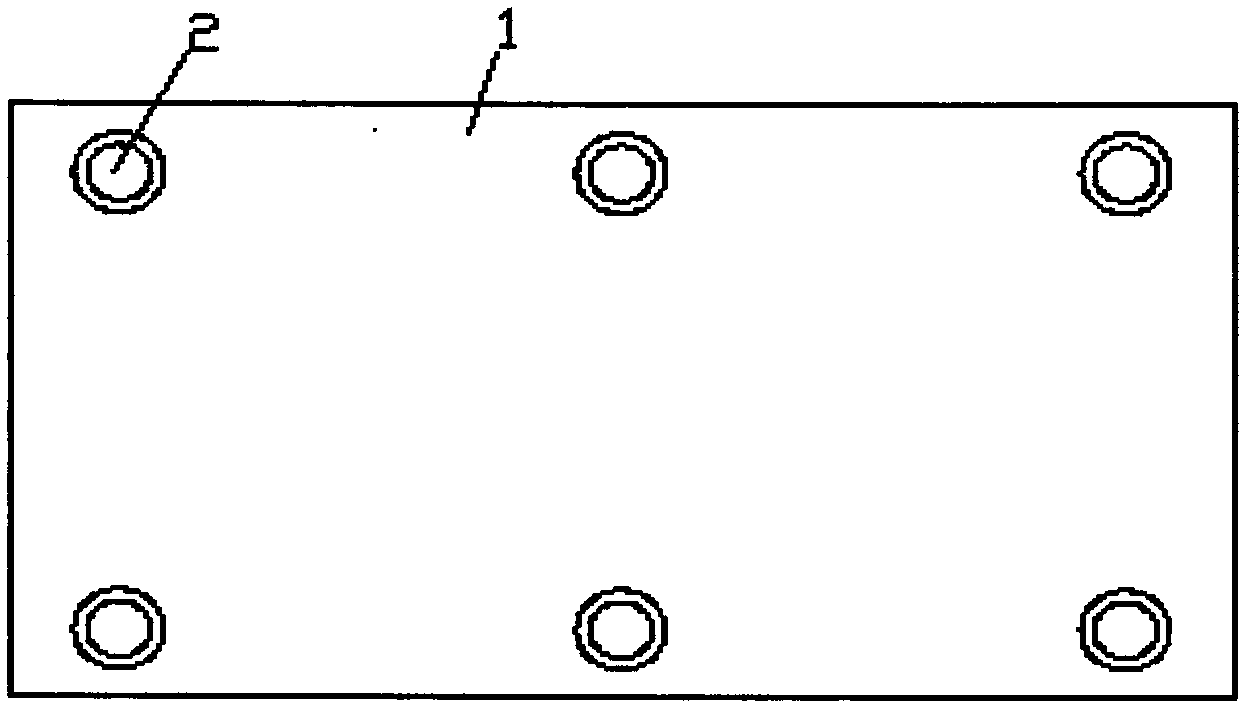

[0027] Such as Figure 1~6 As shown, a wire-wound resistor with an aluminum casing includes an aluminum casing 1 and a resistance skeleton 2; the two ends of the resistance skeleton 2 are connected with resistor lead wires 4, and the multilayer resistance wire 3 is wound on the resistance skeleton 2 Resistor body 9 is formed; isolation insulation sheets 5 are arranged between multilayer resistance wires 3; insulation isolation plates 6 are provided on the upper and lower sides of resistor body 9; The outer side of the insulating isolation plate 6; the resistance skeleton 2 is "I" shaped, and the multilayer resistance wire 3 is wound in the recessed area of the "I" shaped resistance skeleton 2 . The "I" shape resistance frame 2 is adopted, and the resistance wire 3 is completely wound on the recessed part of the resistance frame 2, which ensures the insulation between the resistance wire 3 and the aluminum shell 1; When the wire is connected to the wire, the head must be fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com