Static balance test method applied to gyroscope position marker spindle

A test method and a technology of a position marker, which are applied in the direction of speed measurement by gyro effect, gyroscope/steering sensing equipment, instruments, etc., can solve the problems of high test environment requirements, static unbalance of the position mark, and contamination of the position mark and other problems, to achieve the effect of low test environment requirements, simple test data processing, and high test accuracy indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

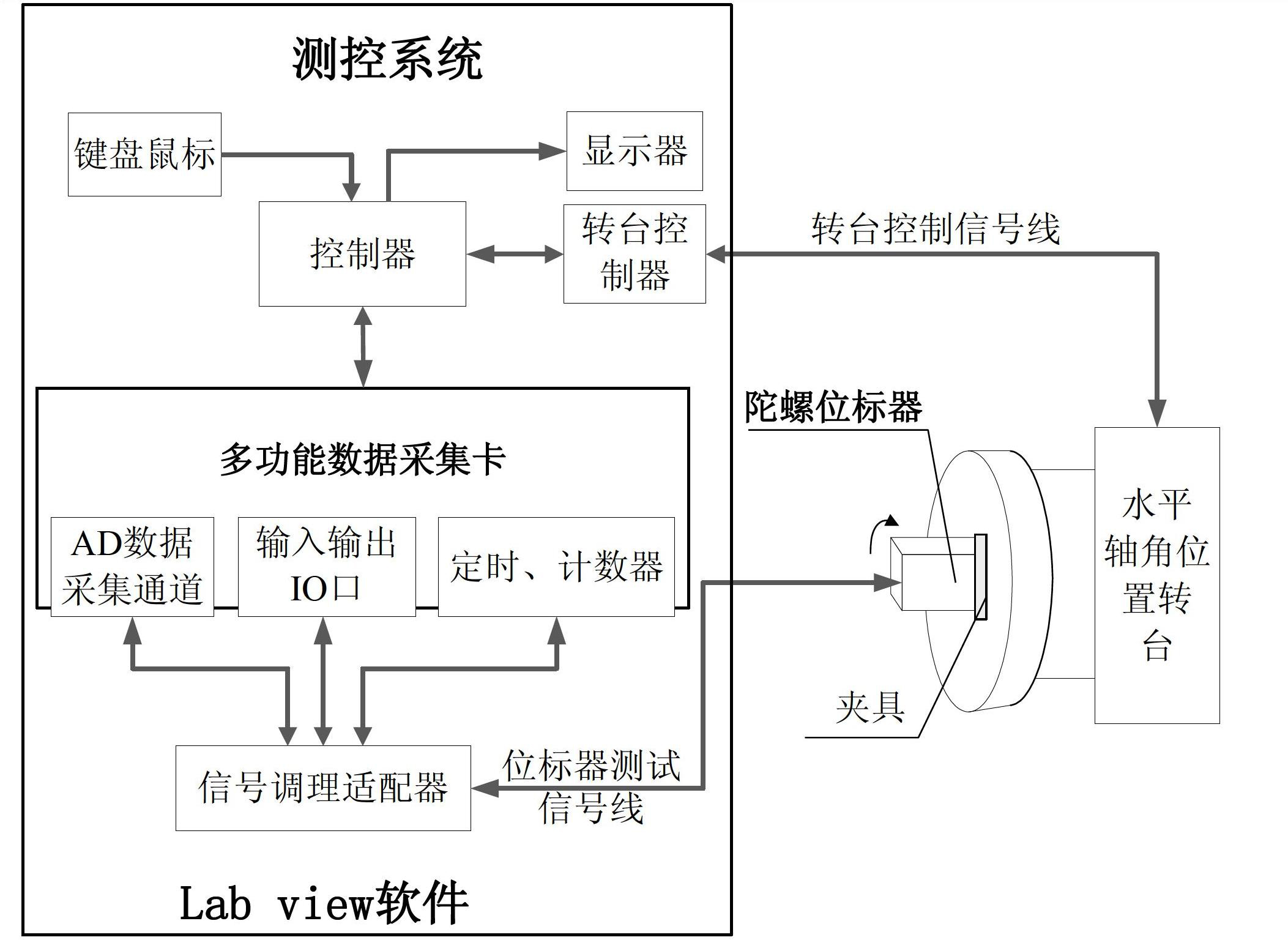

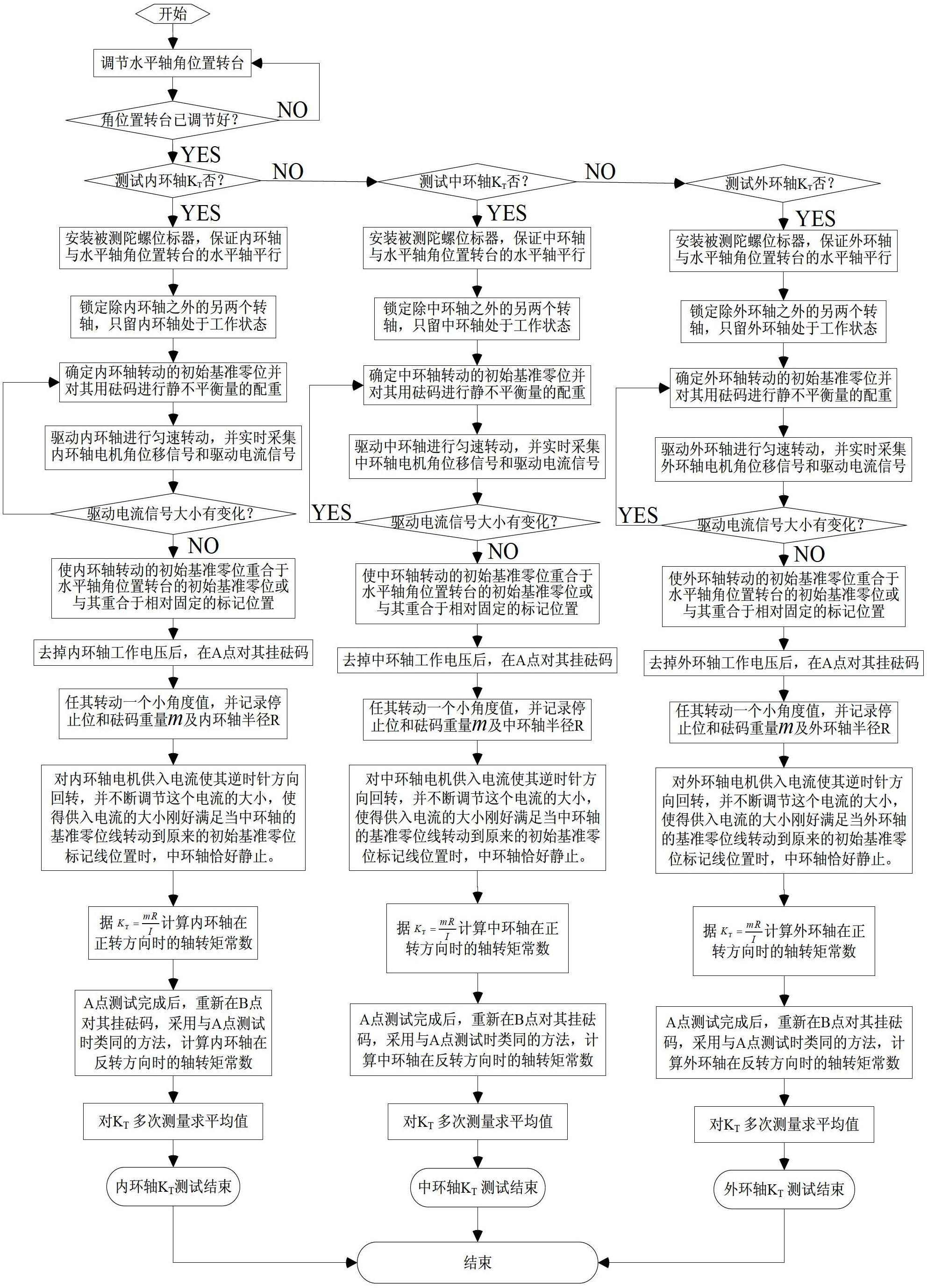

[0026] The present invention relates to a static balance test method for the rotating shaft of a gyro position marker. The structural composition diagram of the system used is as follows figure 1 As shown, the whole system is mainly composed of the tested gyro marker, the horizontal axis angular position turntable, various fixtures and measurement and control systems. The objects of the static balance test are the outer ring, middle ring and inner ring of the gyro marker. When testing the rotating shaft and the system, first use various fixtures to mount the gyro marker on the turntable at the angular position of the horizontal axis, and adjust any one of the three axes of the gyro marker to be measured with the turntable by changing the direction of the installation fixture. The horizontal axis is parallel, and the system monitoring software compiled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com