Half joint sealing gasket

A technology of gaskets and half joints, which is applied in the direction of pipes/pipe joints/fittings, mechanical equipment, pipe components, etc., can solve the problems of dropping, construction personnel's rapid maintenance and construction inconvenience, and gasket dropping, etc., to achieve production and Reduced production cost, no need for bonding process requirements, and high sealing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

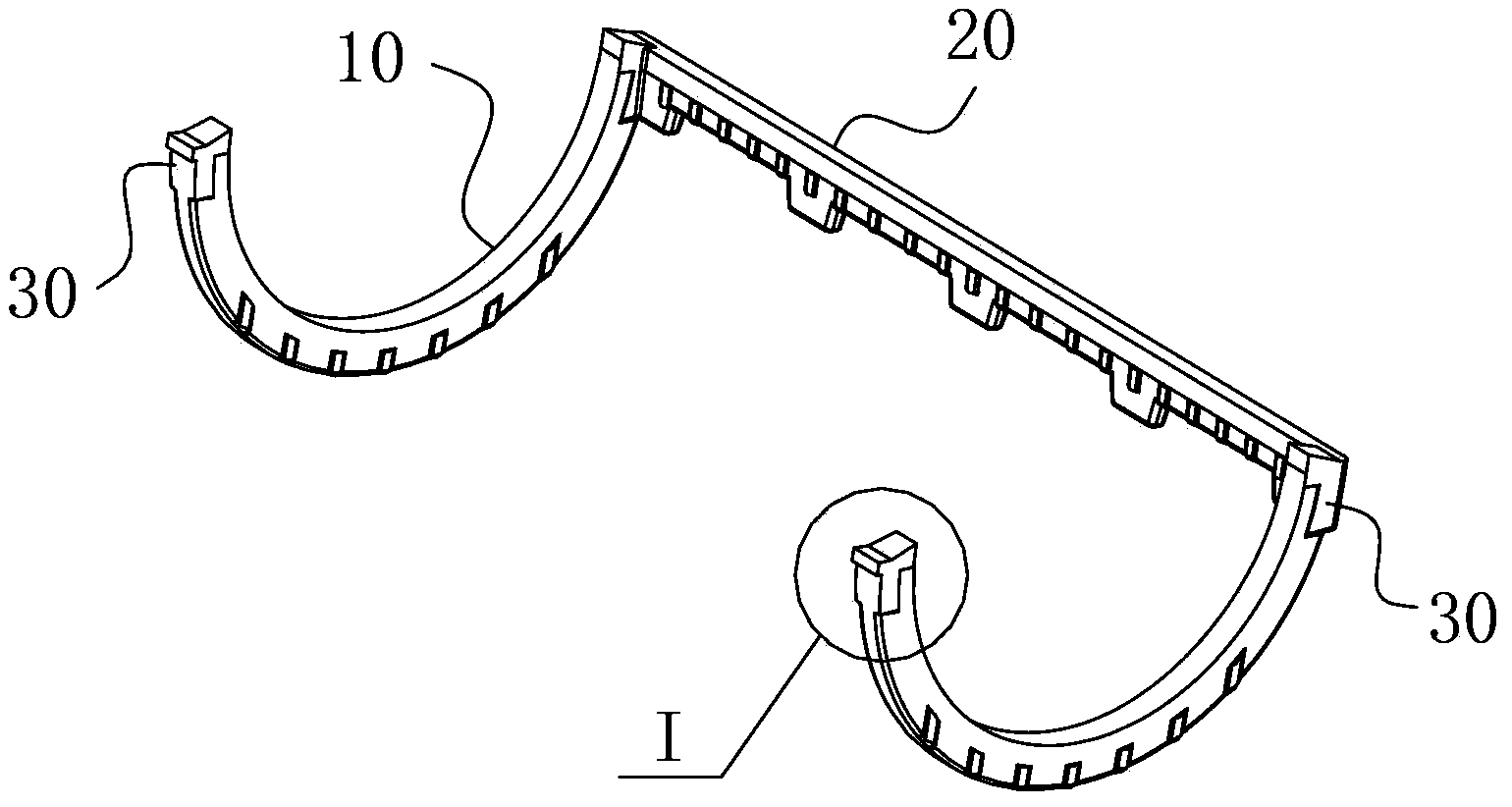

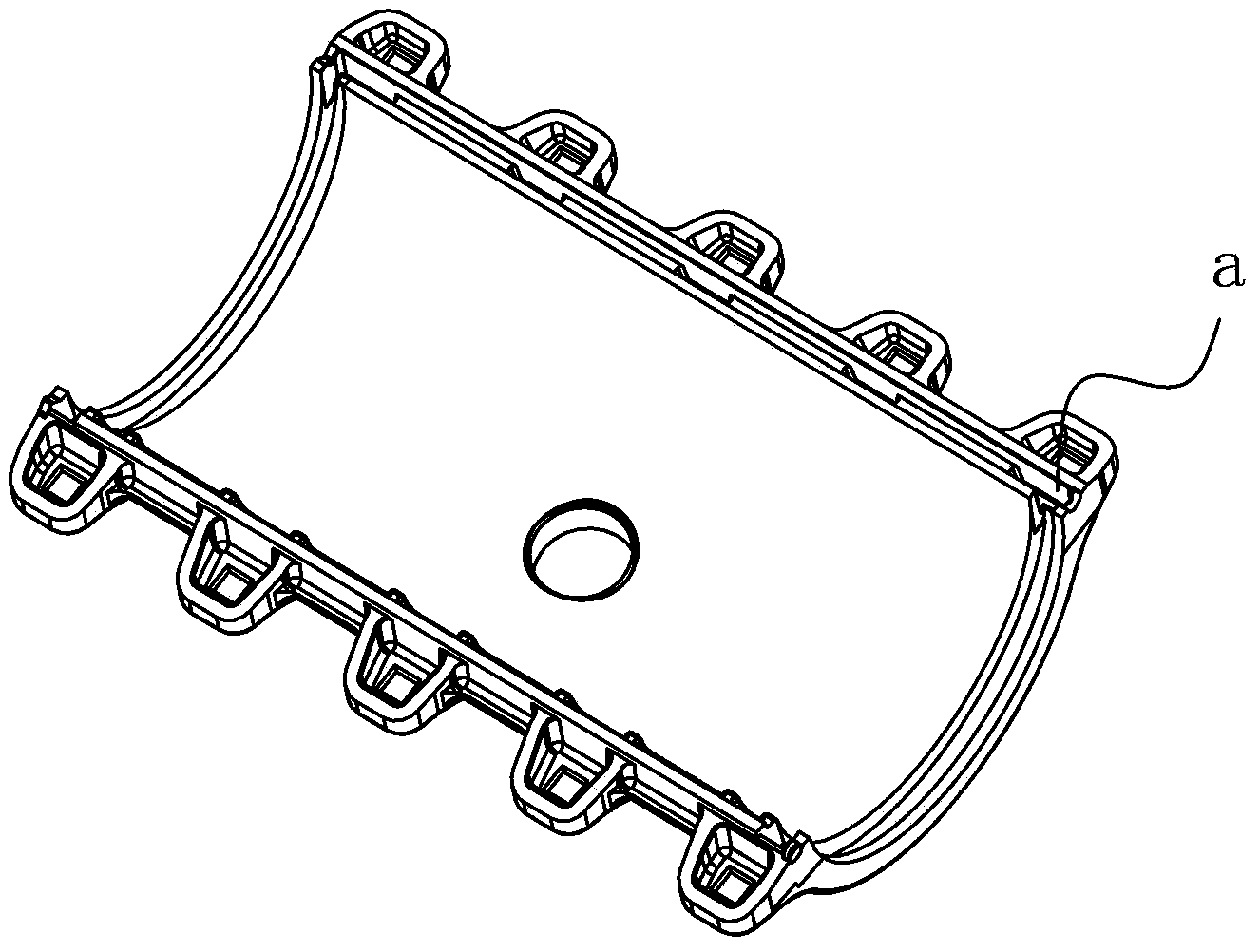

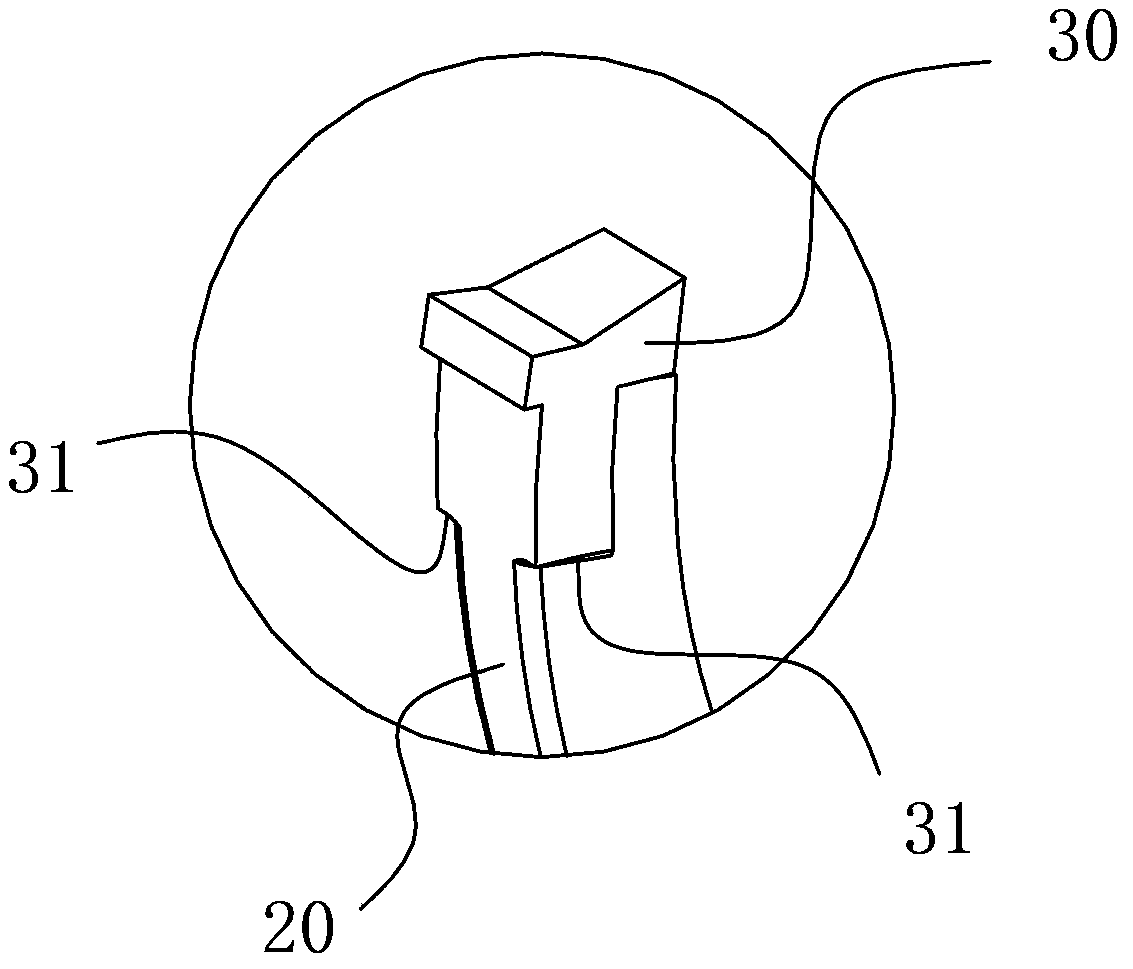

[0010] A kind of half-arc sealing gasket, comprising two opposite semi-arc sealing rings 10 and sealing strips 20 arranged at the ends of the two sealing rings 10 for connecting to each other, and the sealing rings 10 also have A snap-fit part 30 is provided, and the cross-sectional shape of the snap-fit part 30 is a trapezoidal or stepped structure that gradually extends from the outer side of the seal ring 10 to the inside or gradually decreases in steps. Snap fit.

[0011] During actual assembly, such as Figure 1-4 As shown, the cross-sectional shape of the engaging part 30 is more similar to a dovetail shape. During assembly, the sealing ring 10 and the sealing strip 20 can be inserted and fitted with the reserved sinker groove on the half joint shell. At this time The snap-in parts 30 at both ends of the sealing ring 10 can be naturally placed on the corresponding side edges of the housing. The cross-sectional shape of part 30 matches the dovetail-shaped groove par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com