Rotary gas distribution valve

A gas distribution valve, rotary technology, applied in multi-way valves, valve devices, engine components, etc., can solve the problems of high maintenance, high maintenance costs, large equipment investment, complex actions, etc., reducing operating costs and operating reliability. The effect of enhancing and reducing the frequency of equipment shutdown and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

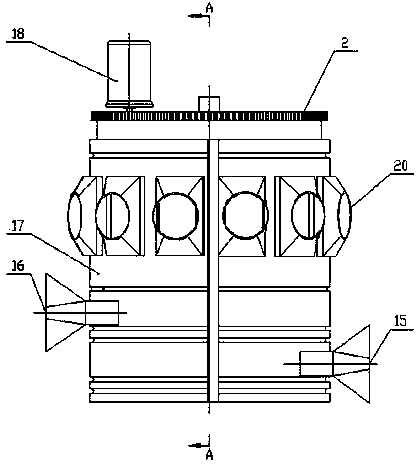

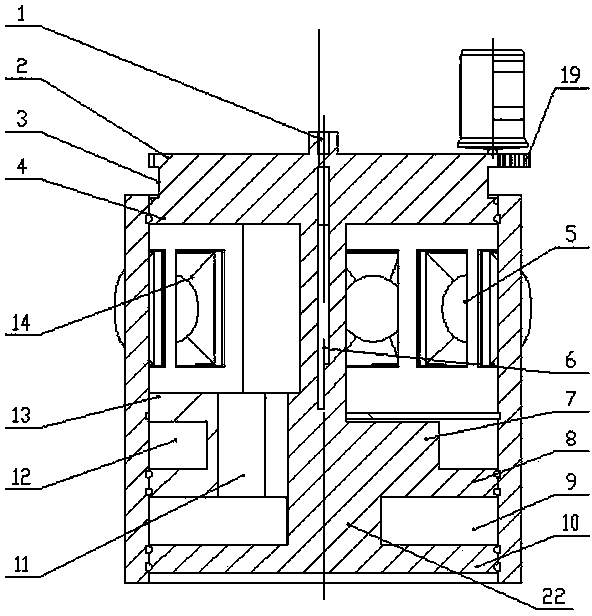

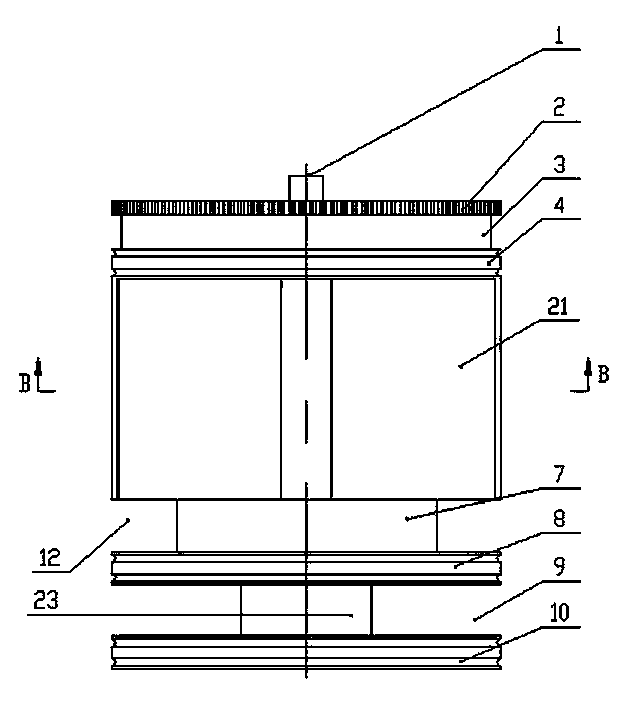

[0018] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the rotary gas distribution valve of the present invention includes a valve housing 17 , a valve core and a motor 18 . The spool contains an upper disc 4, a middle disc 8 and a lower disc 10, the upper surface of the middle disc 8 is connected with a small disc 7 and the two are cast together. The diameter of the small disc 7 is smaller than that of the middle disc 8, and there is a first connecting block 21 between the upper disc 4 and the small disc 7, and the three are cast together. The first connecting block 21 includes two fan-shaped cross-sections, the radial centerlines of the two fan-shaped blocks coincide and their centers are connected as a whole. The upper and lower end surfaces of the first connecting block 21 are respectively cast integrally with the lower surface of the upper disk 4 and the upper surface of the small disk 7 . The smoke distribution chamber 5 is composed of one side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com