Gas compression pump with special-shaped cavity

A technology of compressed air pump and special-shaped cavity, which is applied in the direction of pumps, pump components, rotary piston pumps, etc., which can solve the problems of structural complexity and working range, and achieve the effect of fewer parts, simple structure, and large effective volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

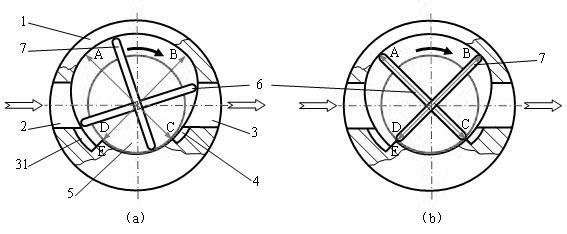

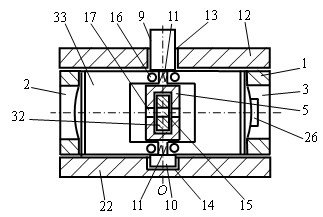

[0042] refer to Figure 1 to Figure 6 . The special-shaped cavity air pump of the present invention includes a stator 1 with a special-shaped cylindrical inner cavity, an inlet 2, an outlet 3, an unloading groove 4 and a pressure balance groove 31, and an upper cover plate 12 and a lower cover plate 12 installed on both ends of the stator 1. The cover plate 22 constitutes a sealed cavity, and the rotor is installed in the sealed cavity.

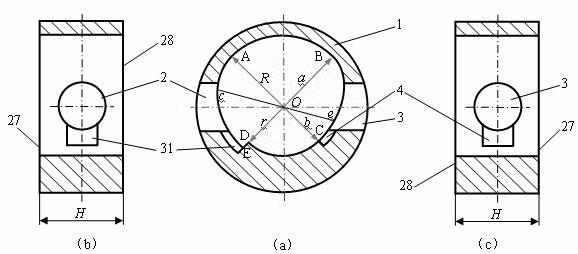

[0043] The special-shaped cylindrical inner cavity of the stator 1 is composed of a quarter circular arc surface AB, a transitional arc surface BC, a quarter circular arc surface CD, a turning plane DE and a limit curved surface EA; a quarter circular arc The surface AB and the quarter arc surface CD are coaxial, and the common axis is O (see figure 2 , image 3 ). The centers of curvature of the ends B and C on the transition arc surface BC are located on the common axis O of the quarter arc surface AB and the quarter arc surface CD; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com