Split bucket of chain type grooving machine

A groove forming machine and chain technology, which is applied in the direction of earth mover/excavator, construction, etc., can solve the problems of time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

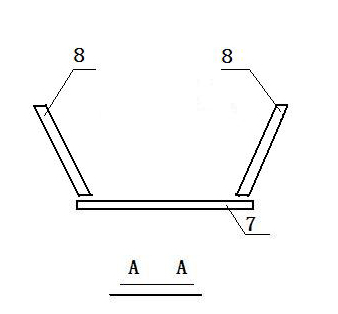

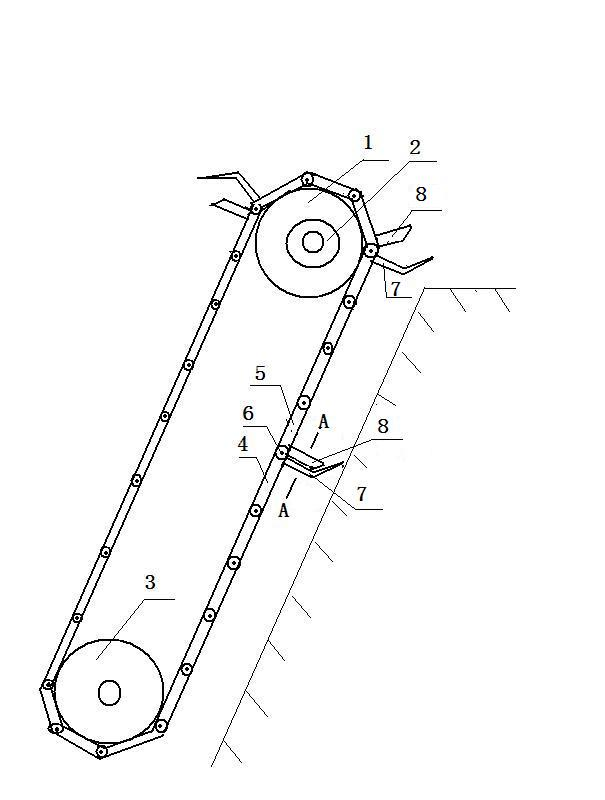

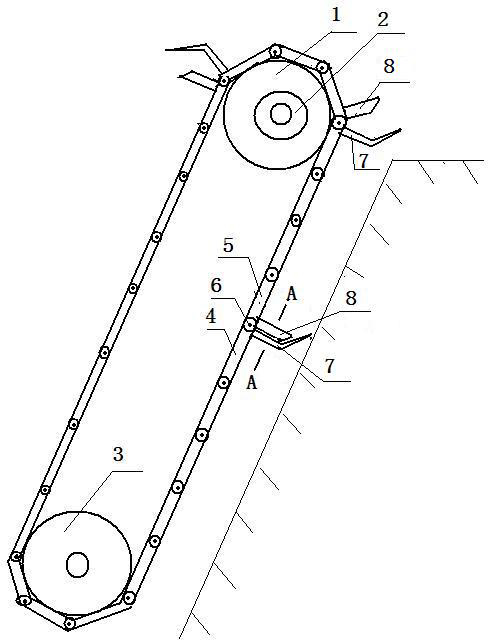

[0012] attached figure 1 It is a specific embodiment of the present invention. In this embodiment, the hydraulic motor 2 and the driving gear 1 driven by it are set at the upper end of the slotting machine, and the driven wheel 3 is set at the lower end of the slotting machine. The chain rotates around the driving gear and the driven wheel. In the system, the chain is composed of multiple chain links, and its special feature is that the bucket is composed of a bucket bottom 7 and two side walls 8, one end of the bucket bottom 7 is fixed on the upper end of the chain link A4, and the two side walls 8 One end of the chain link B5 is fixed on the lower end of the chain link B5, and the chain link A and the chain link B are pinned through the pin shaft 6. When the chain link A and the chain link B form 180 degrees, the lower ends of the two side walls are close to the bottom of the bucket, and the side walls The upper end of the bucket is inclined outwards relative to the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com