Washing machine timer capable of controlling circulating water flow and double-barrel washing machine

A technology for controlling cycles and timers, which is applied to washing machine appliances, washing machines with containers, and other washing machines. It can solve the problems of reduced washing efficiency, high power consumption, unfavorable washing liquid or washing powder dissolution, etc., to improve washing performance, Increase function and improve the effect of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

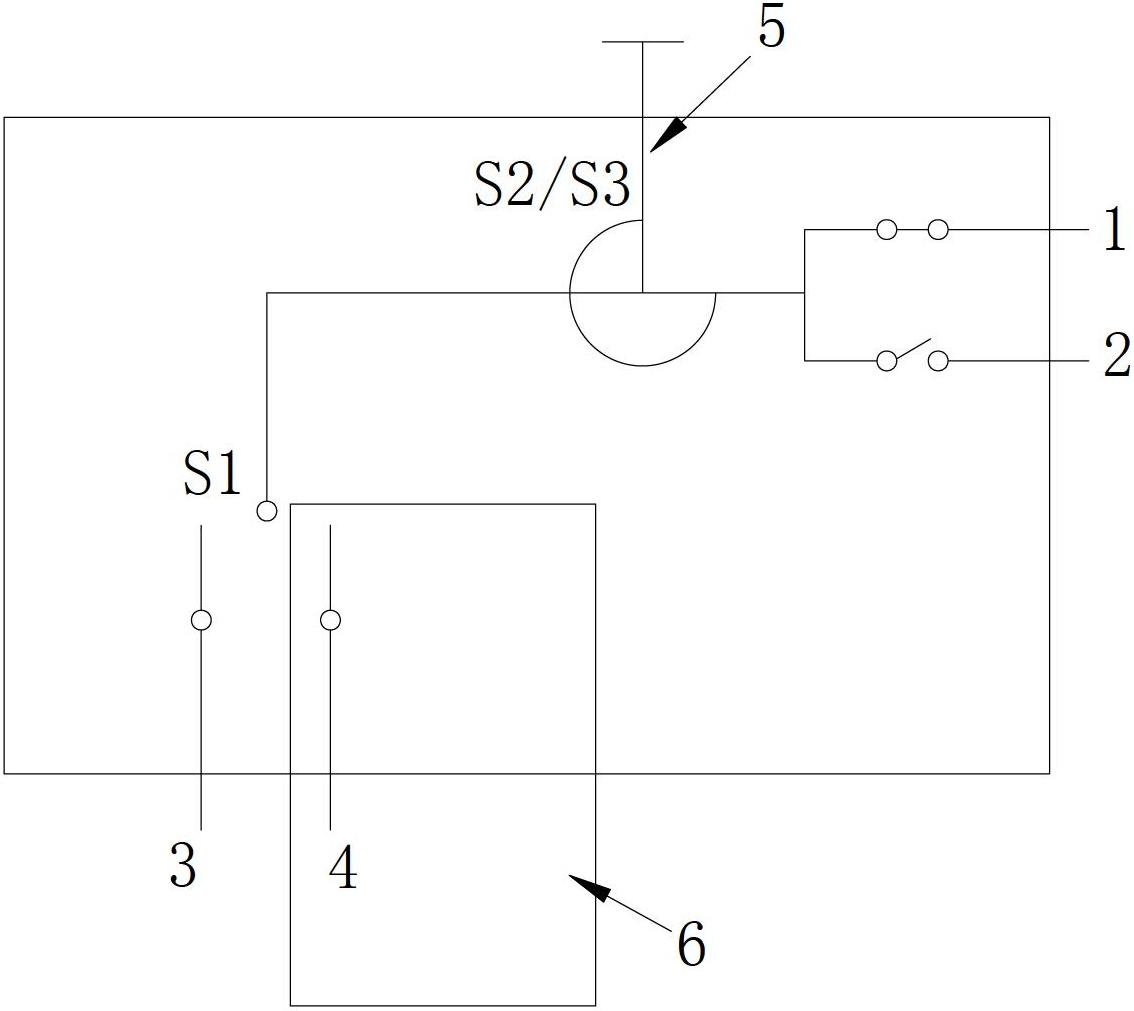

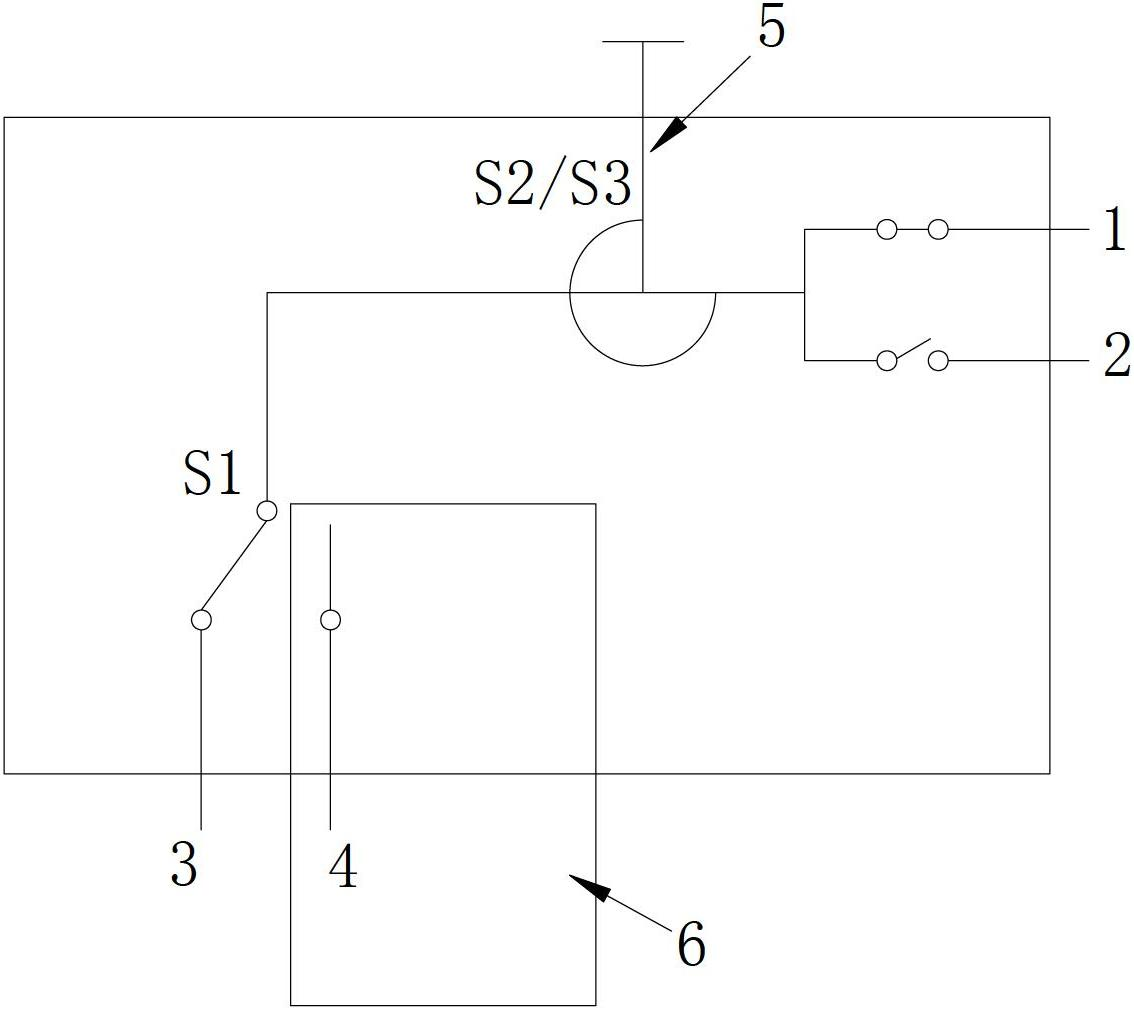

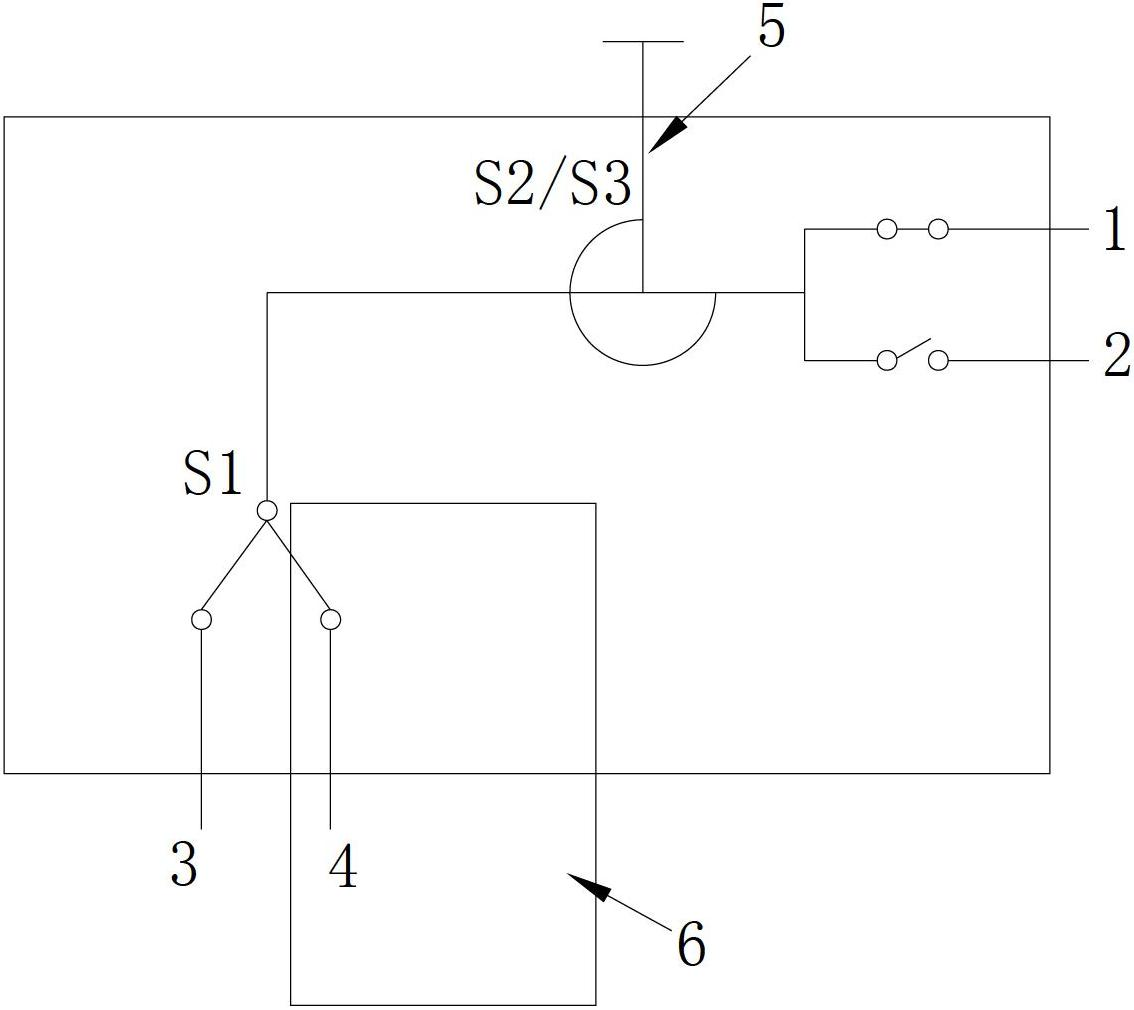

[0040] When the timer described in this embodiment selects the water flow I corresponding to S2 to act, the washing contact 1 is closed, the washing contact 2 is disconnected, and the washing cam operation control contact 1 is pressed. Figure 5 The a1, a2, b1, b2 in the cycle are closed and disconnected periodically, realize the positive and negative rotation of the washing motor, and perform soaking and washing. The closing and opening time of the washing contact 1 is according to Table 1, and the synchronization starts in the first cycle The cycle cam control contact 4 is closed and disconnected in a cycle of 1min and 5min, and the inner circulation water flushing is carried out until the soaking and washing time runs T1 time; when entering the continuous washing time, the washing cam control contact 1 is pressed Figure 5 The c1, c2, d1 and d2 in the cycle are closed and disconnected to realize the positive and negative rotation of the washing motor, and the continuous wash...

Embodiment 2

[0043] The difference between this embodiment and Embodiment 1 is that the manual switch selects the water flow II corresponding to S3, and when soaking and washing, the cycle is closed and disconnected according to a3, a4, b3, b4, and the continuous washing time is according to c3, c4, d3 , d4 is the cycle closure and disconnection. During the soaking and washing time period, the washing cam controls the power contacts to work in a cycle of 12.5s for washing and 47.5s for soaking. This process and the flushing with circulating water flow in the continuous washing process are the same as those in Embodiment 1.

Embodiment 3

[0045] The difference between this embodiment and the above-mentioned embodiment 1 and embodiment 2 is that only during the soaking and washing time, the on-off of the contact of the drainage pump is controlled to realize the internal circulating water flow flushing, while the internal circulating water flow flushing is not performed during the continuous washing time .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com