Plastic circular weaving machine

A technology of circular looms and plastics, applied in circular looms, looms, textiles, etc., can solve the problems of weaving speed, power consumption constraints, increased equipment costs, and heavy load on the balance wheel, so as to reduce the failure rate and prevent cloth efficiency, increase the weaving speed and simplify the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

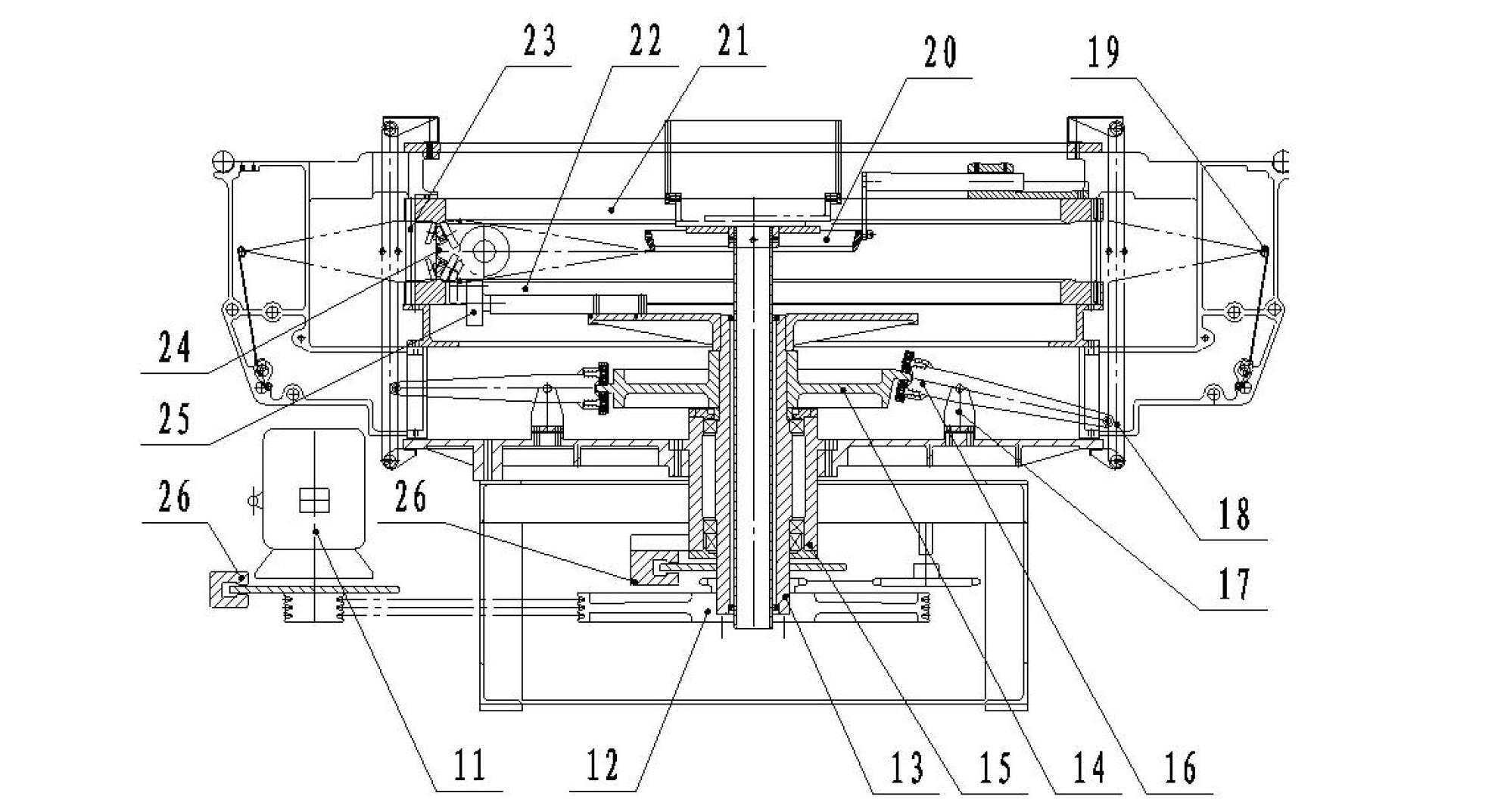

[0023] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

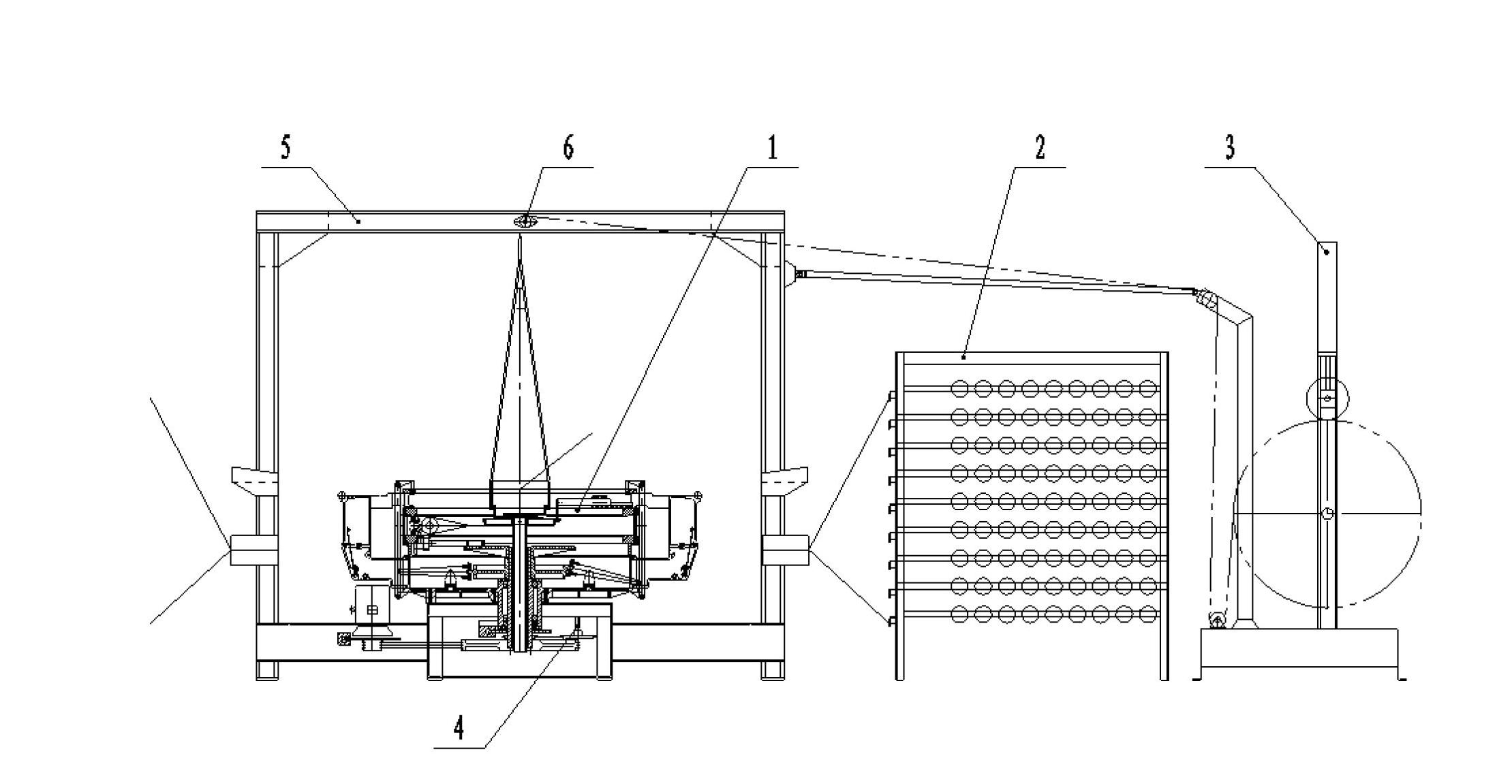

[0024] Such as figure 1 , figure 2 The structure of the present invention shown is a plastic circular loom, including a main machine 1, a let-off system 2, a winding device 3, and a frame 5; the main machine 1 includes a main motor 11, a transmission system, and a warp opening and delivery mechanism And the weft insertion mechanism, the weft insertion mechanism includes an upper door ring 21, a lower door ring 22, a connecting column 23, a shuttle 24 and a propeller 25; the transmission system includes a pulley 12, a main shaft 13, and a support 14.

[0025] In order to solve the problems existing in the current known technology ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com