Aluminium electrolytic cell emergency short-circuit bus

A short-circuit bus, aluminum electrolytic cell technology, applied in the field of electrolytic cell bus, can solve the problems of inability to realize short-circuit, long installation time, inconvenient handling, etc., achieve significant economic and social benefits, restore normal production, and shorten the short-circuit process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

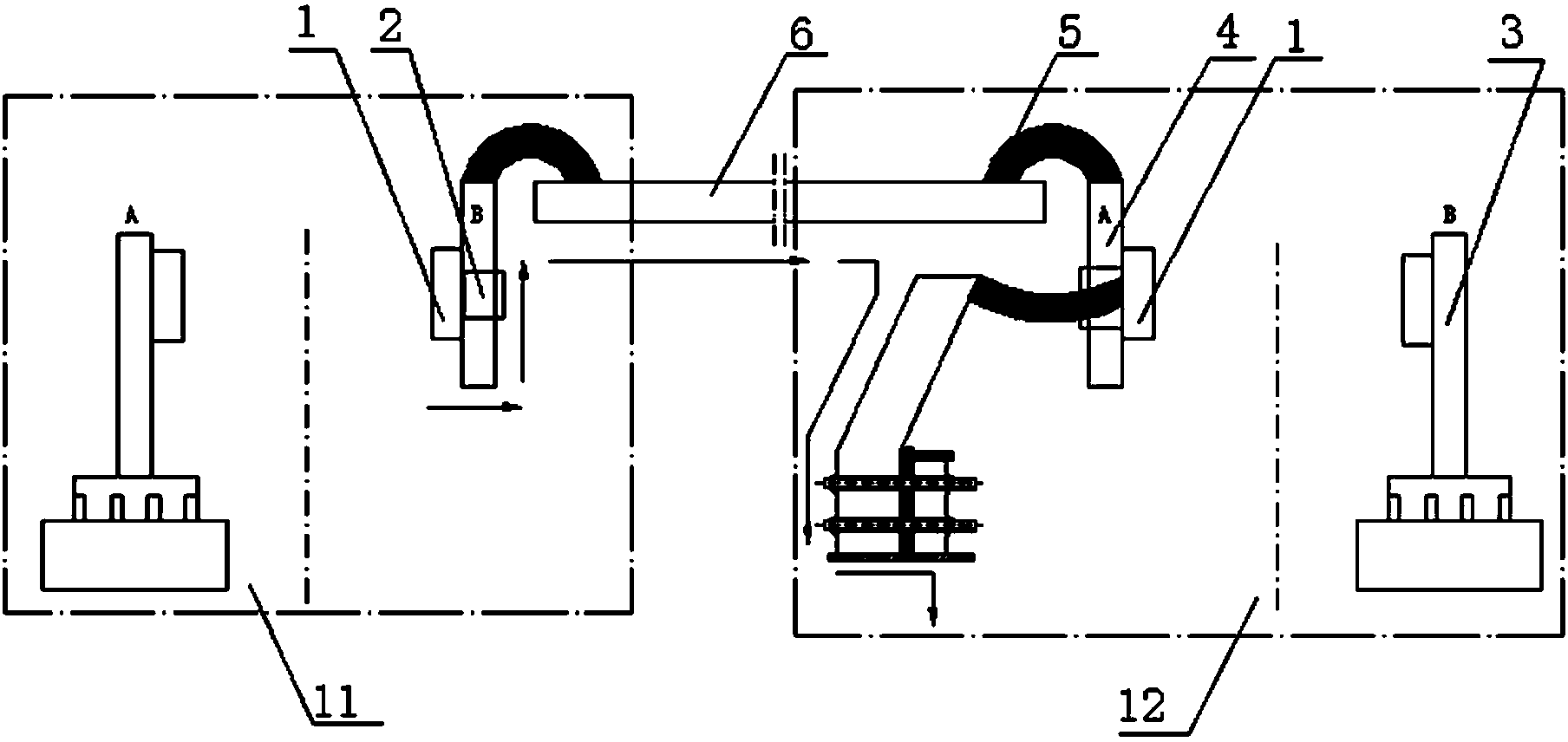

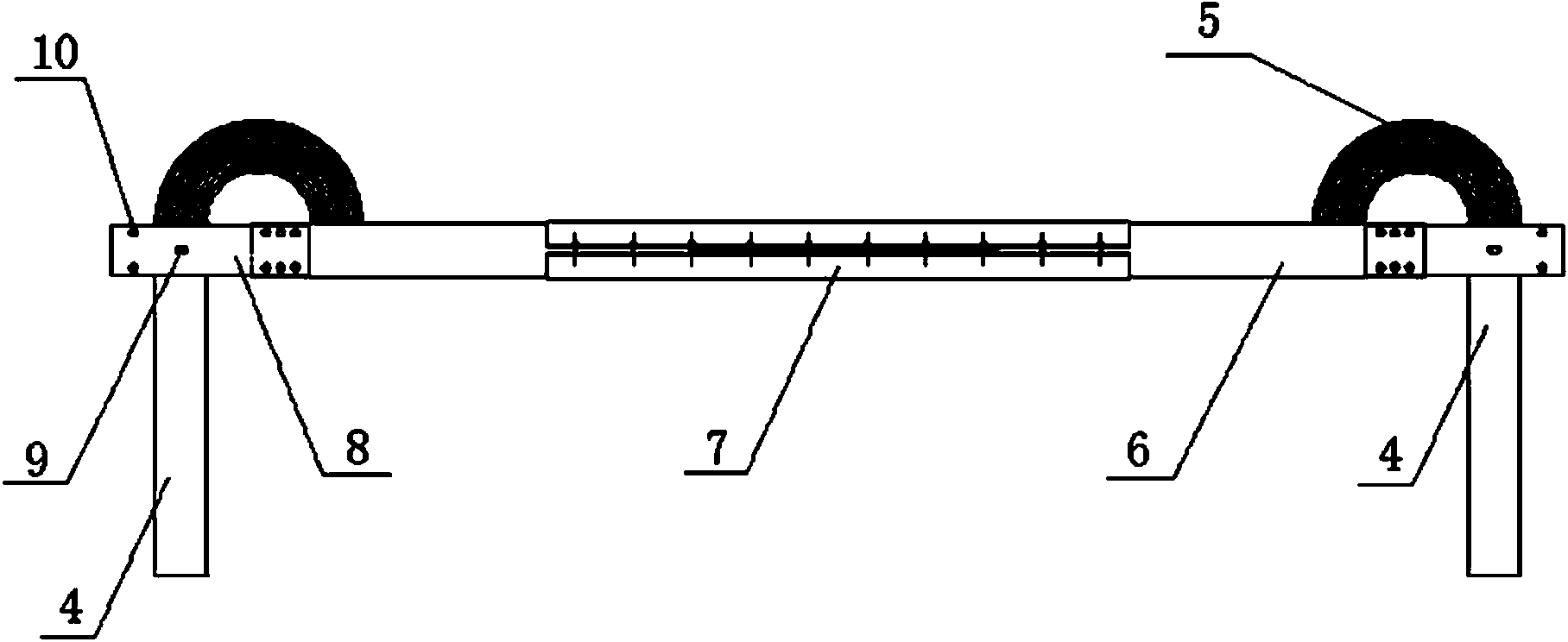

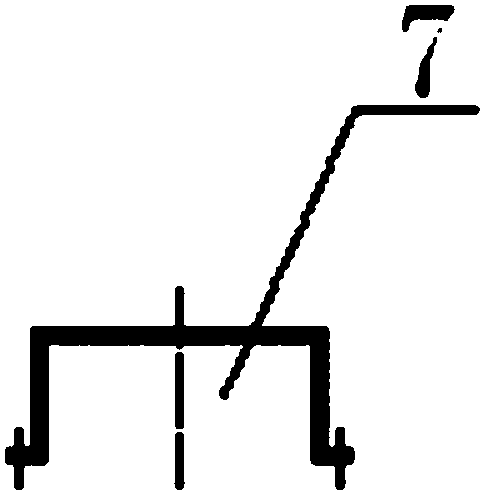

[0018] Such as figure 1 with figure 2 As shown, an emergency short-circuit bus bar of an aluminum electrolytic cell includes a diversion bus bar 6 and an aluminum soft connection 5, and the upper ends of the diversion bus bar 6 are respectively welded with one end of the semicircular arc-shaped aluminum soft connector 5 by argon arc welding, and the aluminum The other end of the soft connection 5 is respectively welded with the upper part of the short-circuit bus 4 by argon arc welding, and the two short-circuit buses 4 are perpendicular to the diversion bus 6 and are located below the diversion bus 6 . The cross-sectional dimensions of the diversion bus 6 and the short-circuit bus 4 are the same as those of the anode guide rod 3 , mainly to facilitate the fixed connection of the short-circuit bus 4 to the anode bus 1 through the small box clamp ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com