Anticorrosion protection method for high-speed braking disc of wind generating set

A wind turbine, anti-corrosion protection technology, applied in the direction of superimposed layer plating, solid-state diffusion coating, coating, etc., can solve problems such as easy to generate corrosion, constraints, and threats to the safe operation of the brake system of wind turbines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

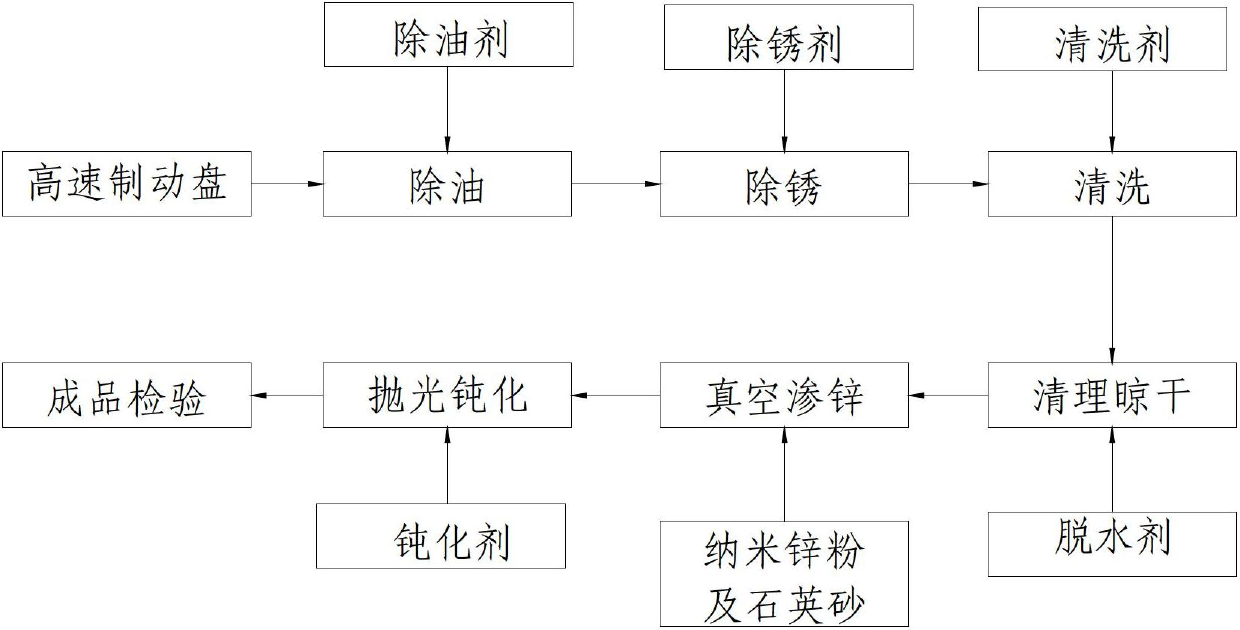

[0015] An anti-corrosion protection method for a high-speed brake disc of a wind power generating set, the steps are as follows:

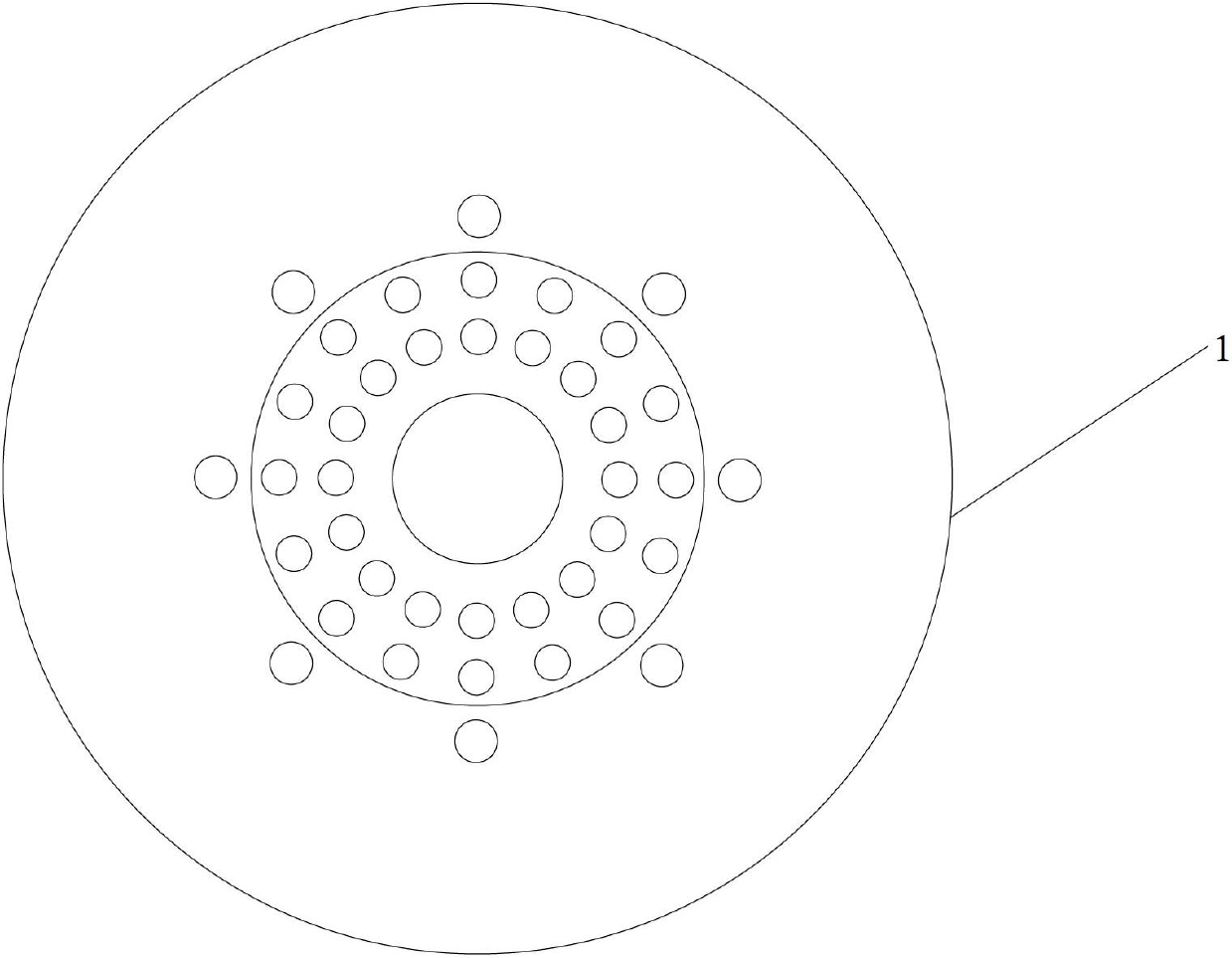

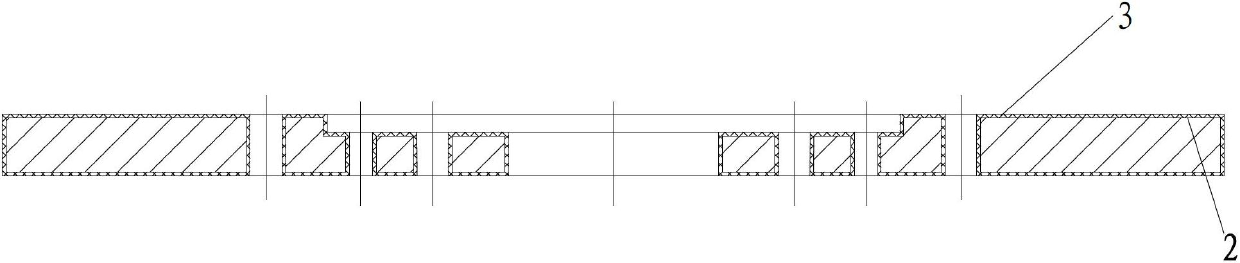

[0016] First of all, the high-speed brake disc 1 made of Q345D steel is subjected to surface cleaning treatment, especially the brake friction surface 2 of the high-speed brake disc 1. The surface cleaning treatment includes degreasing agent, rust remover, cleaning agent, dehydration degreasing, derusting, cleaning, and drying the high-speed brake discs in turn.

[0017] Then, the high-speed brake disc 1 in the above steps is subjected to an anti-corrosion treatment, the anti-corrosion treatment is to carry out a zinc-seeding treatment to the high-speed brake disc 1, and the zinc-seeding treatment is to process the high-speed brake disc 1, zinc powder and The inert medium is mixed and placed in a vacuum-sealed stainless st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com