Method and device for accurately feeding mannheim reaction furnace

A precise feeding, Mannheim furnace technology, applied in sustainable manufacturing/processing, sulfate/bisulfate preparation, climate sustainability, etc., can solve the problem of uneven particle size, floating, unstable product control, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

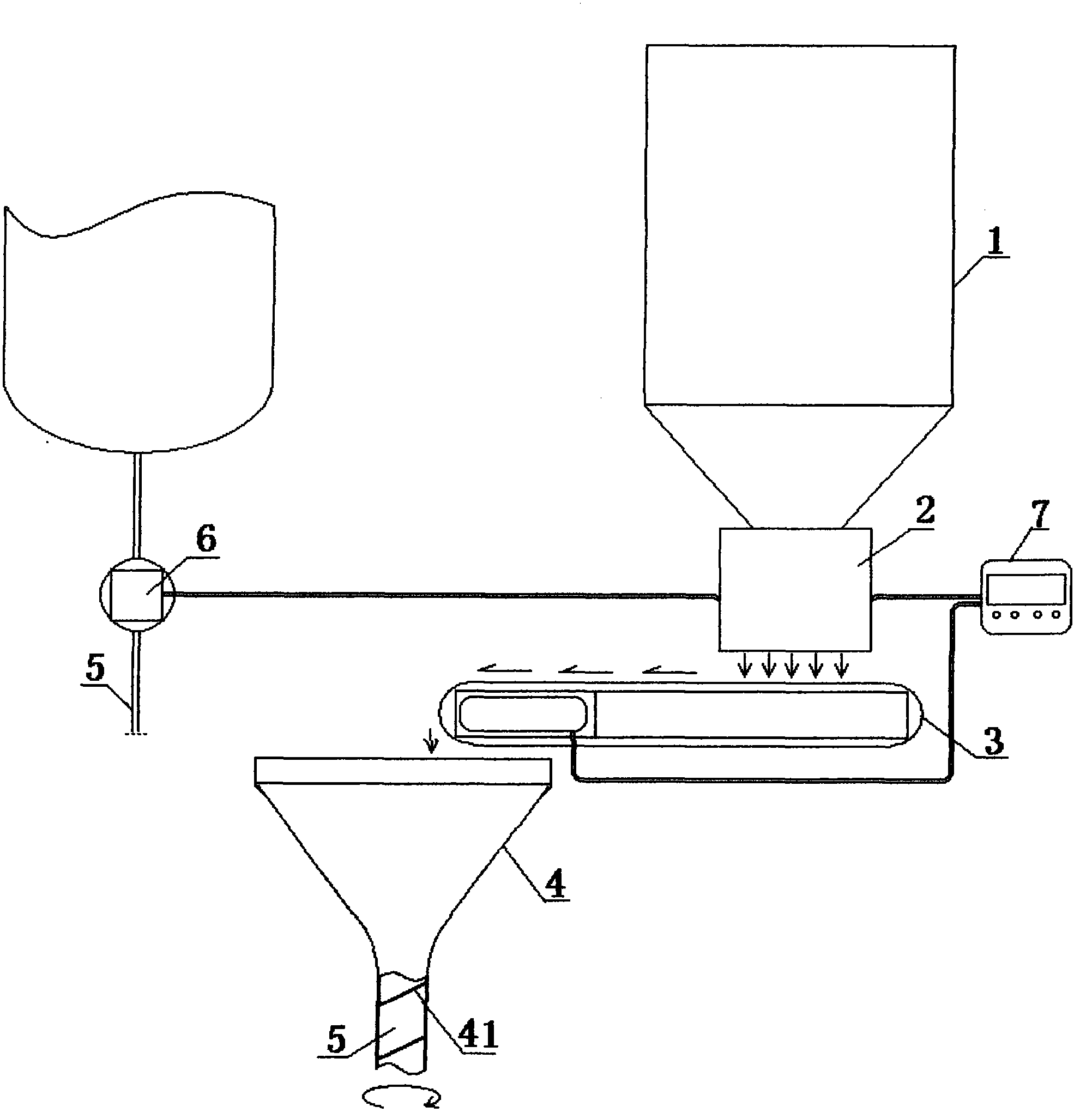

[0026] Embodiment two, such as figure 2 As shown, the automatic and precise Mannheim reactor feeding device of the utility model is configured with a feeder 2 at the lower end of the potassium chloride feeding bin 1, and an electronic belt weigher 3 is arranged below the feeder 2, and the discharge end of the electronic belt scale 3 The lower part is equipped with a feeding hopper 4 that matches the feeding port of potassium chloride in the Mannheim furnace; the feeding pipe 5 connected with Mannheim sulfuric acid is equipped with an electronically controlled metering valve 6, and the metering result signal output end of the electronic belt scale 3 is connected to the feeding automatic controller The potassium chloride feed weight signal input end of 7, the sulfuric acid feed amount control signal output end of the automatic feed controller 7 is connected to the control signal input end of the electronic control metering valve 6.

[0027] The feed hopper 4 is equipped with a ro...

Embodiment 3

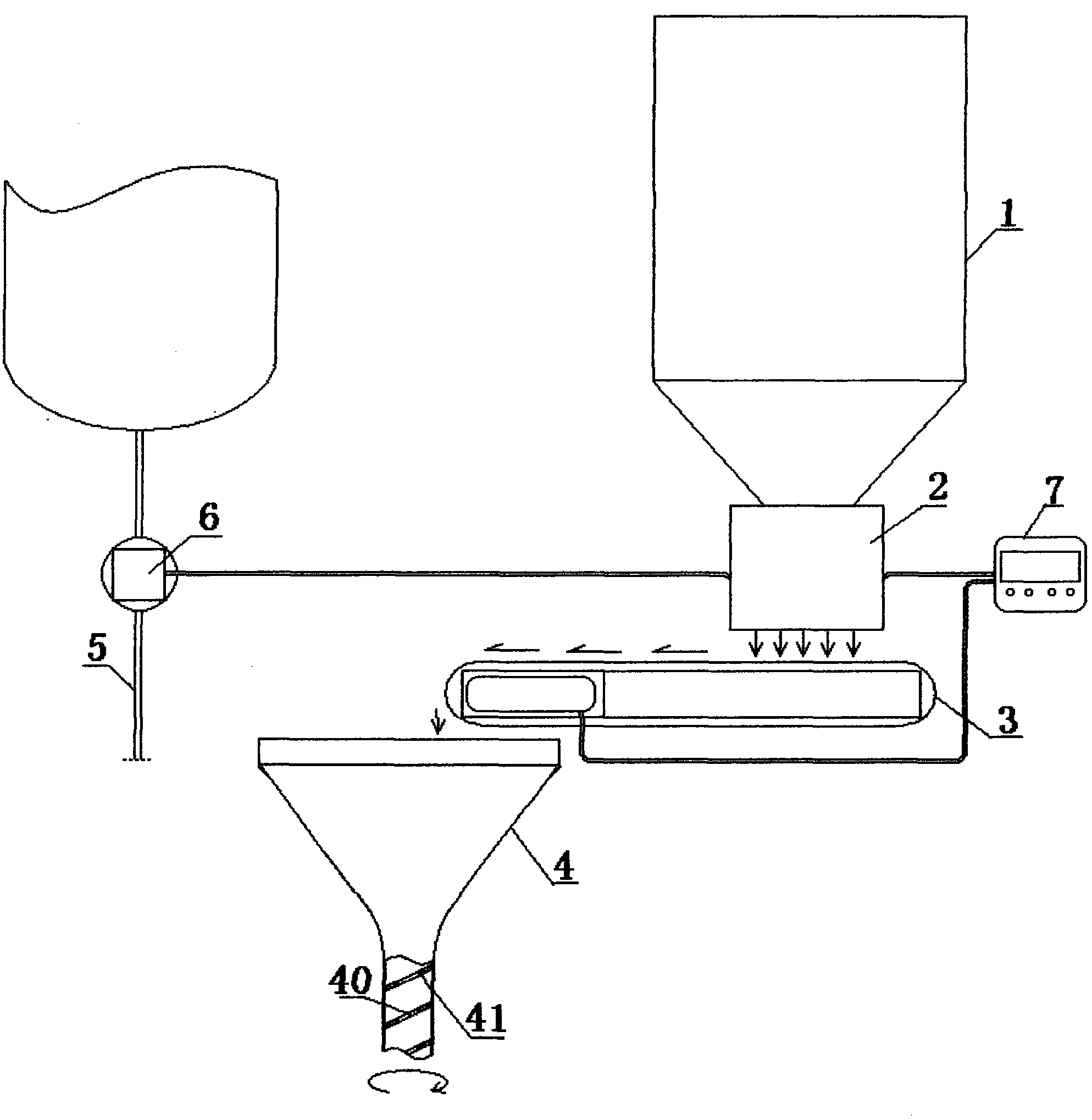

[0028] Embodiment three, such as image 3 As shown, the difference between the automatic and precise Mannheim reactor feeding device of the present invention and Embodiment 2 is that the spiral feeding plate 41 is a hollow spiral feeding plate with a vertical central through hole 40 .

Embodiment 4

[0029] Embodiment four, such as Figure 4 As shown, the difference between the automatic and precise Mannheim reactor feeding device of the utility model and the second embodiment is that: a screw feeder driven by a rotary drive device is arranged in the feeding cavity of the feeding hopper 4, and the screw feeder Be the spiral feeding plate 41 that central shaft 44 is installed (or be the center is shaped on the hollow spiral feeding plate of vertical through hole, perhaps be the solid plate type spiral feeding plate, perhaps be the feeding material that is arranged on the helical shape that is fixed on the central shaft tooth). The spiral conveying plate can also be called a stirring cage. The rotary driving device includes a variable frequency motor 82 controlled by an automatic controller, and the variable frequency motor 82 drives the screw feeder through a reduction transmission mechanism. More specifically: the upper end of the central shaft 44 and the screw feeding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com