One-stage hydrogen separating and purifying method based on pressure swing adsorption membrane and device for realizing same

A pressure swing adsorption and membrane separation technology, applied in hydrogen separation, using solid contact hydrogen separation, etc., can solve the problems of waste of resources, will not exceed 99.8%, reduce one-time investment and other problems, achieve low cost, reduce scale, Yield-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

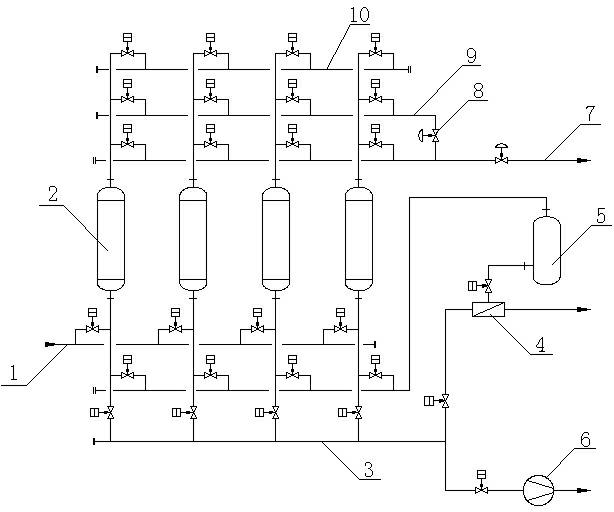

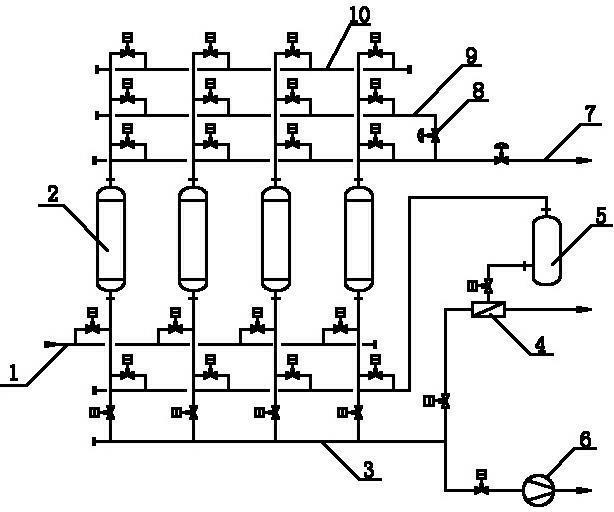

Image

Examples

Embodiment

[0025] The method for separating and purifying hydrogen by one-stage pressure swing adsorption membrane of the present embodiment comprises the following steps:

[0026] a. Adsorption: The raw material gas with hydrogen content of 75%, carbon dioxide content of 24.5%, carbon monoxide content of 0.5%, and pressure of 1.2Mpa is sent into the adsorption tower in sequence according to a certain time interval and divided into different periods. The adsorption tower is filled with hydrogen purification adsorbents, which absorb carbon dioxide and carbon monoxide in the raw material gas by using different adsorption capacities for different components. The effective gas component hydrogen is output from the top of the adsorption tower, and the product hydrogen is sent to the device through the outlet valve. User, at this time the hydrogen content is above 99.9%;

[0027] b. Regeneration: After the raw material gas is absorbed in the adsorption tower for 240 seconds, the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com