Two-level discharging device

A technology of feeder and feeder, which is applied in the field of machinery, can solve the problems of large fluctuations in product uniformity and thickness, large fluctuations in material volume in storage boxes, large fluctuations in discharge speed, etc., and achieve good economic benefits , Guarantee product quality and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments described herein are merely illustrative of the spirit of the invention. Those skilled in the art to which the present invention belongs can make various modifications or supplements to the described specific embodiments or adopt similar methods to replace them, but they will not deviate from the spirit of the present invention or go beyond the definition of the appended claims range.

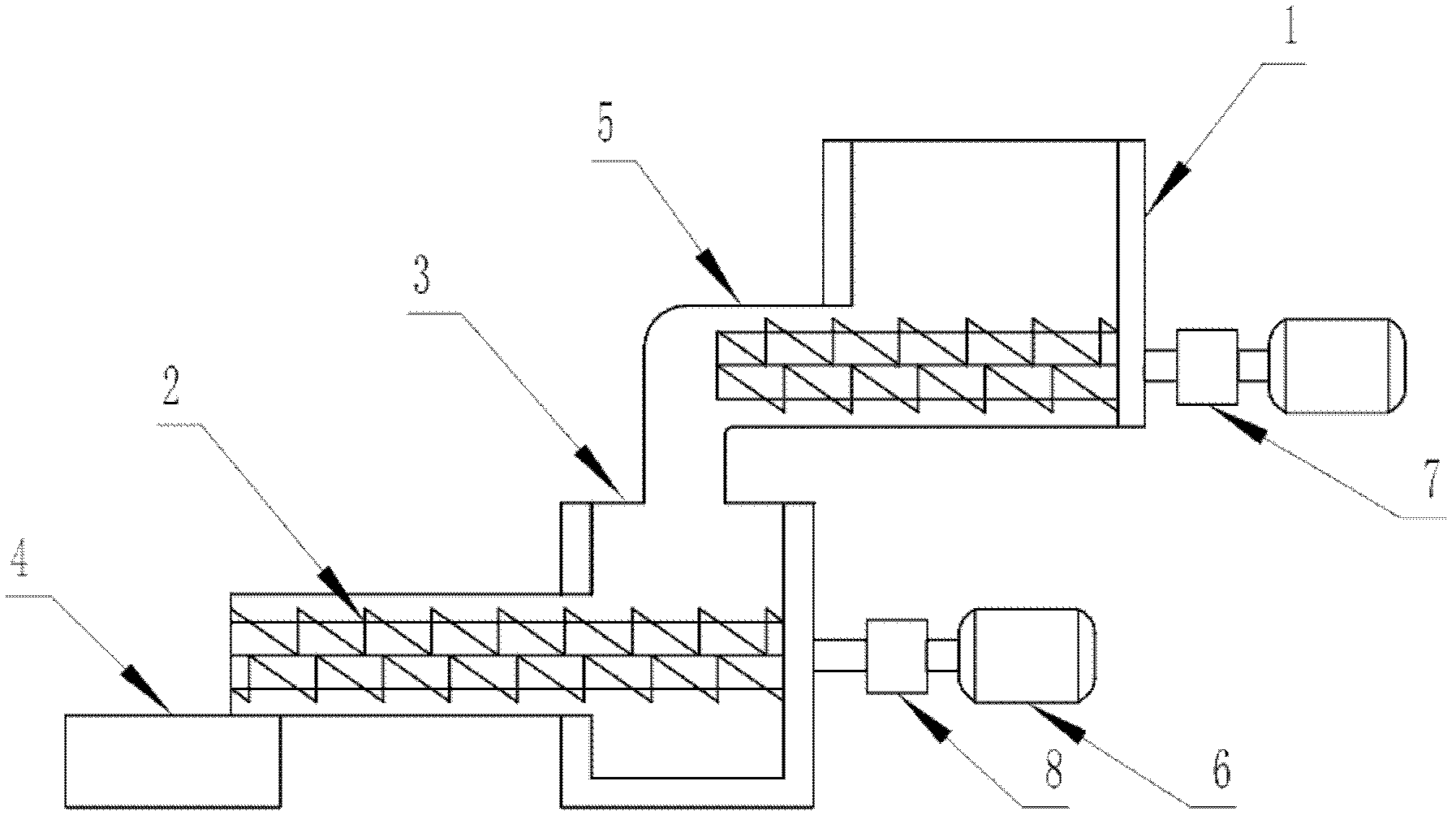

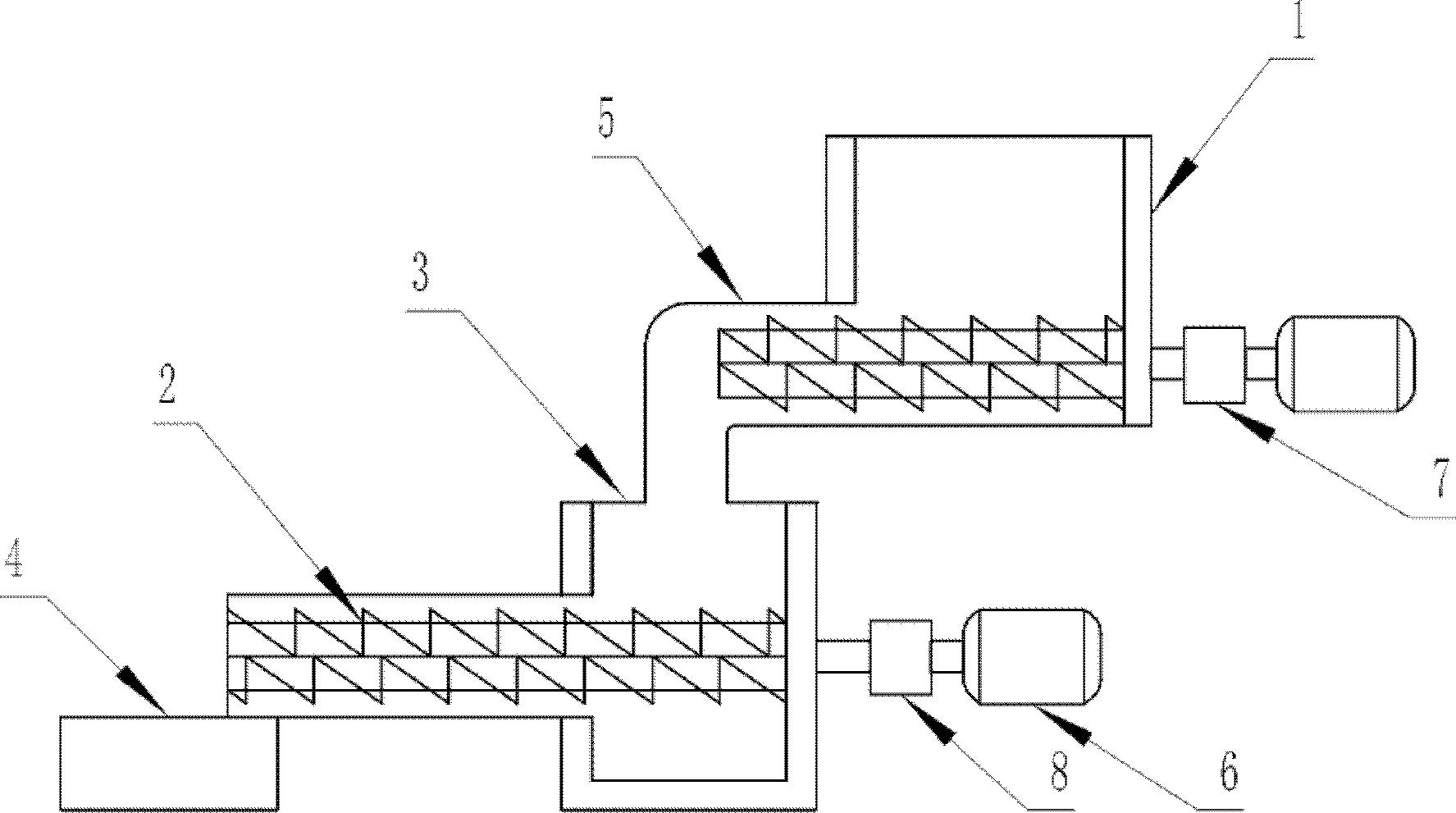

[0018] Such as figure 1 As shown, the two-stage feeder of this embodiment includes a first-stage feeder 1 and a second-stage feeder. The first stage feeder includes twin-screws and a motor that drives the twin-screws. A gearbox I7 is arranged between the twin-screws and the motor. The discharge port of the first stage feeder is connected with the feed port of the second stage feeder through the feed pipe 5 . The second-stage feeder includes a material storage box 3 and a twin-screw rod 2. The lower part of the material storage box is horizontally provided wit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap