Polyhedral rolling mechanism

A technology of polyhedron and motor base, which is applied in the direction of motor vehicles, transportation and packaging, etc., to achieve the effect of simple control, increased rigidity and uniform distribution of force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in conjunction with accompanying drawings.

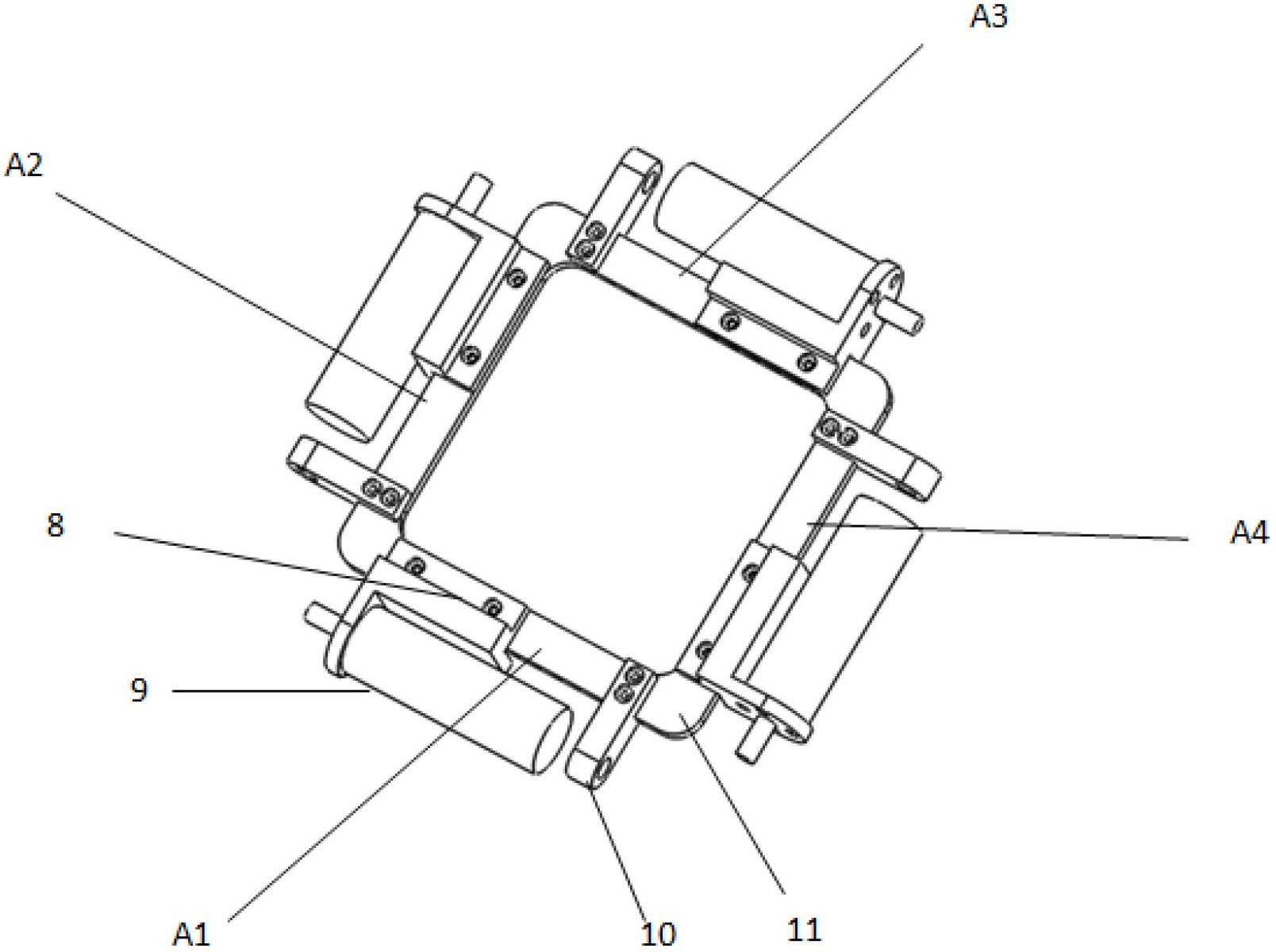

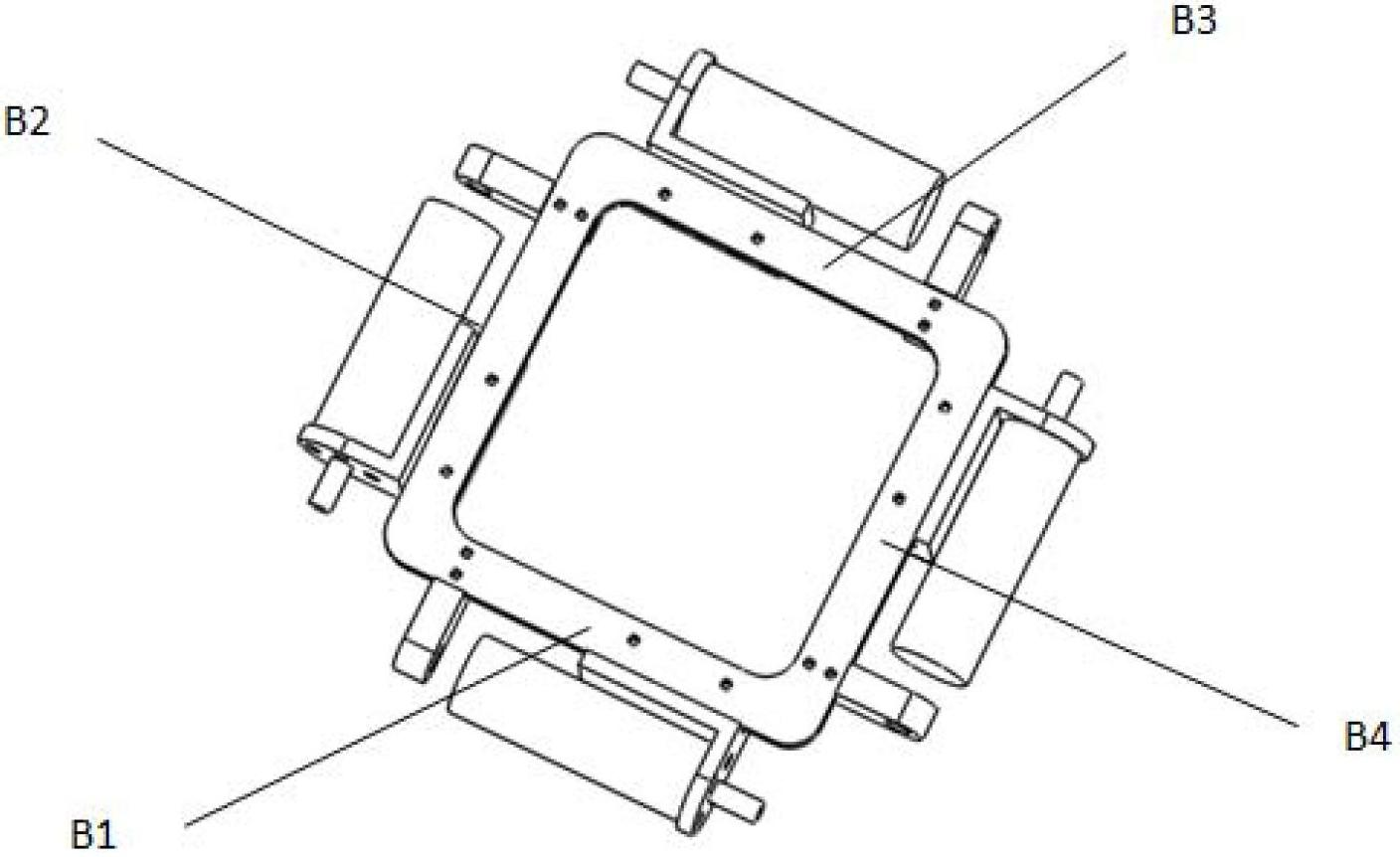

[0026] A polyhedron rolling mechanism, the mechanism includes an upper platform A, a lower platform B and a first branch chain L1, a second branch chain L2, a third branch chain L3 and a fourth branch chain L4, the lower platform A and the upper platform The structure size of B is the same, and the structure and size of the first branch L1, the second branch L2, the third branch L3 and the fourth branch L4 are the same, as figure 1 shown.

[0027] Such as figure 2 , image 3 As shown, the upper platform A includes a square piece 11 and four motor seats 8 evenly arranged on the four sides (A1, A2, A3, A4) of the square piece 11, four motors 9 and four Adapter 10;

[0028] On the side A1 of the square piece 11, an adapter 10 and a motor base 8 are fixed by screws, and a motor 9 is fixed on the motor base 8, and the fixing method on the other three sides is the same as that on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com