Power unit suspension structure for electric vehicle

一种动力单元、电动车辆的技术,应用在电动力装置、下部结构、动力装置等方向,能够解决橡胶套件破损、不能有效地吸收、结构易于与动力单元接触等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Now, the present invention will be described in detail based on the illustrated embodiments.

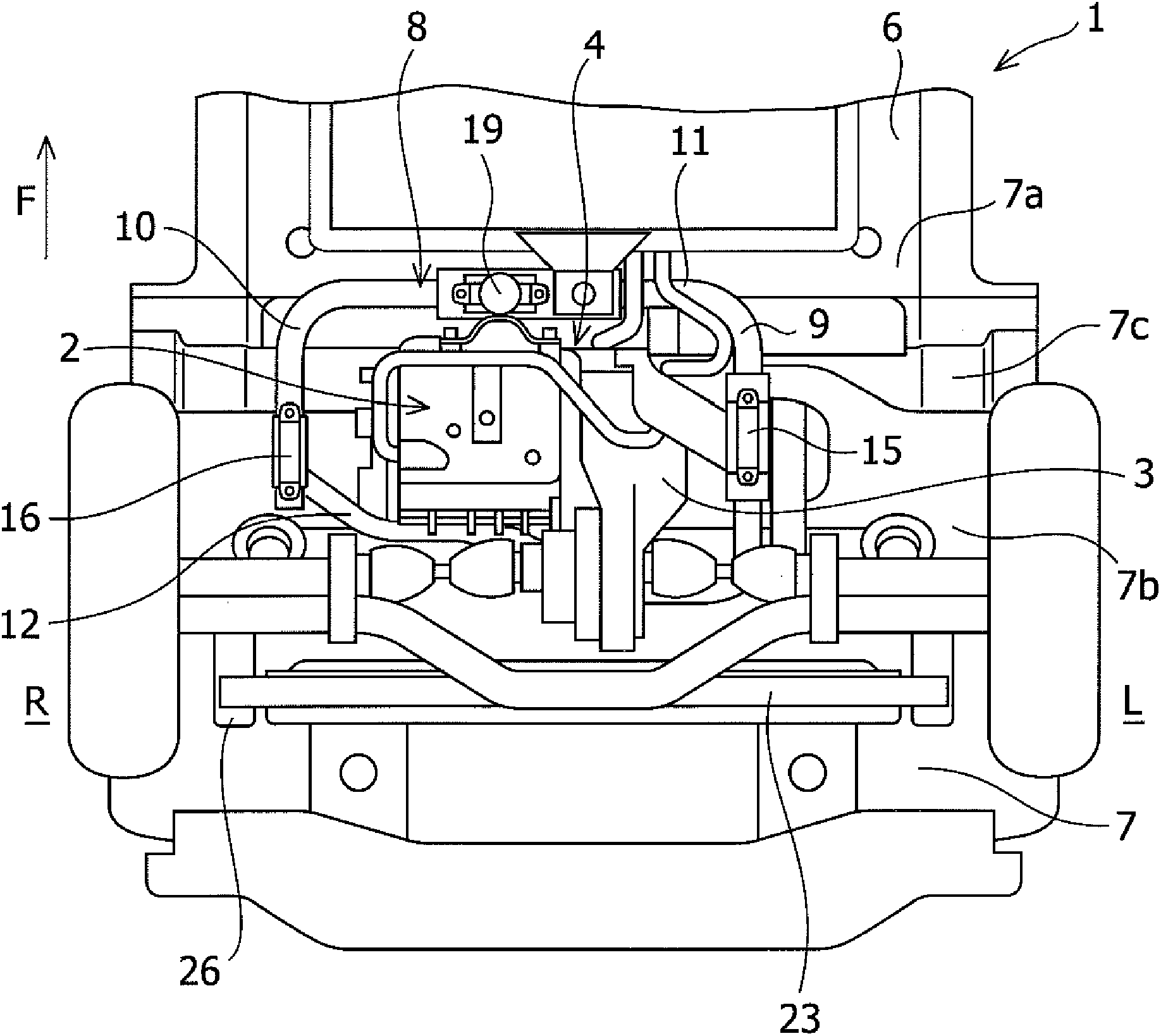

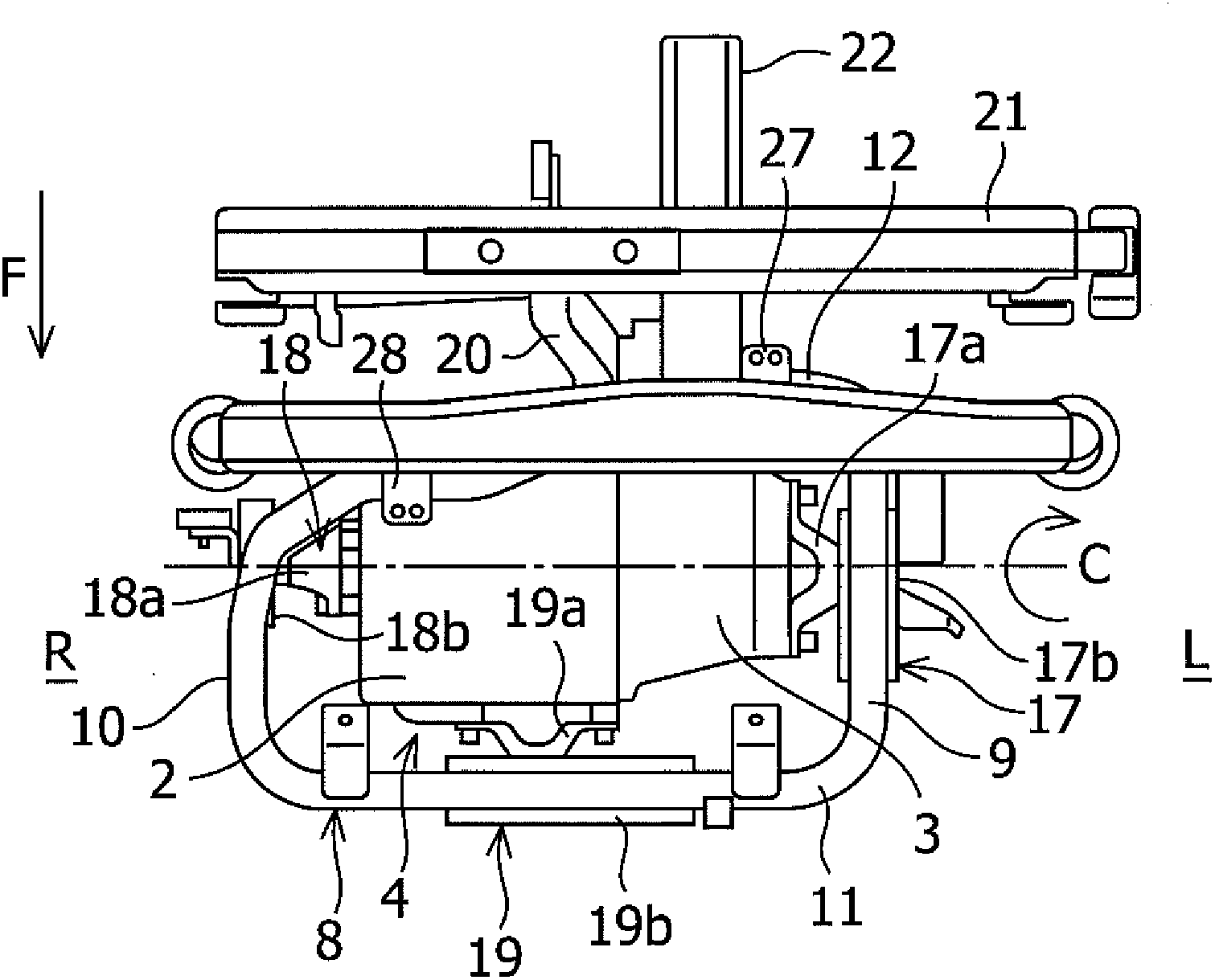

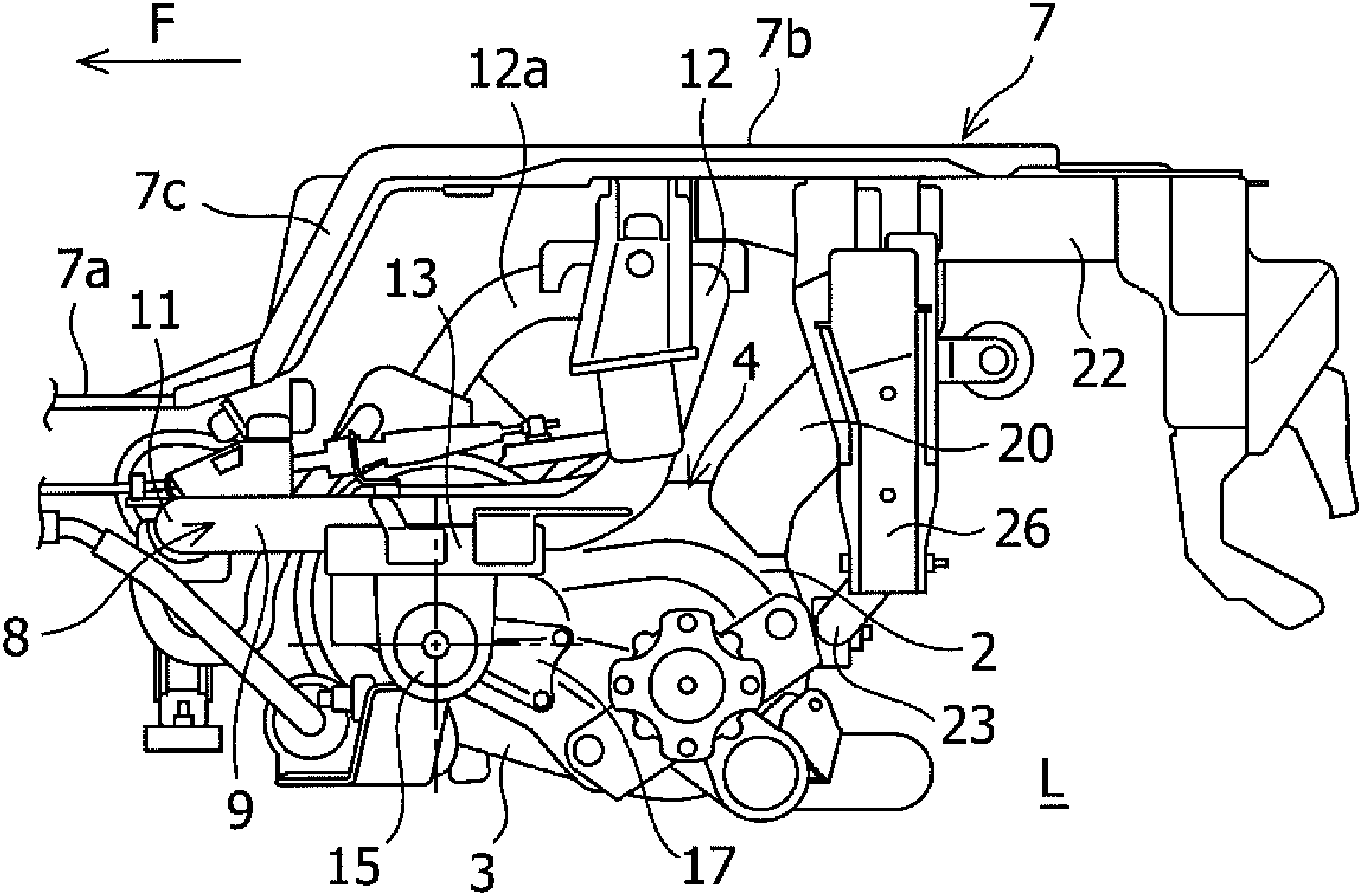

[0034] Figure 1 to Figure 5 A power unit suspension structure for an electric vehicle according to an embodiment of the present invention is shown.

[0035] A vehicle to which the power unit suspension structure according to the embodiment of the present invention is applied is the electric vehicle 1 . The electric vehicle 1 is a rear-drive vehicle such as a commercial vehicle, and travels with the driving force of a motor (electric motor) supplied with electric power. Such as Figures 1 to 5 As shown, a power unit 4 including a motor 2 and a motor reducer 3 is mounted on the rear of the electric vehicle 1 . A shaft C common to the motor 2 and the motor reducer 3 is arranged along the vehicle width direction.

[0036] The power unit 4 is configured such that the motor reducer 3 is connected to the left side of the motor 2 in the vehicle width direction, and the length dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com