Single-side surface layer densification processing method and product for wood

A processing method and densification technology, applied in the direction of wood compression, wood impregnation, wood impregnation, etc., can solve the problems of a lot of glue, waste of chemicals, unsuitable for solid wood floors, etc., to shorten production time, reduce drying steps, and product stability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0019] Example. A method for densification of a single-sided surface layer of wood, comprising the following steps:

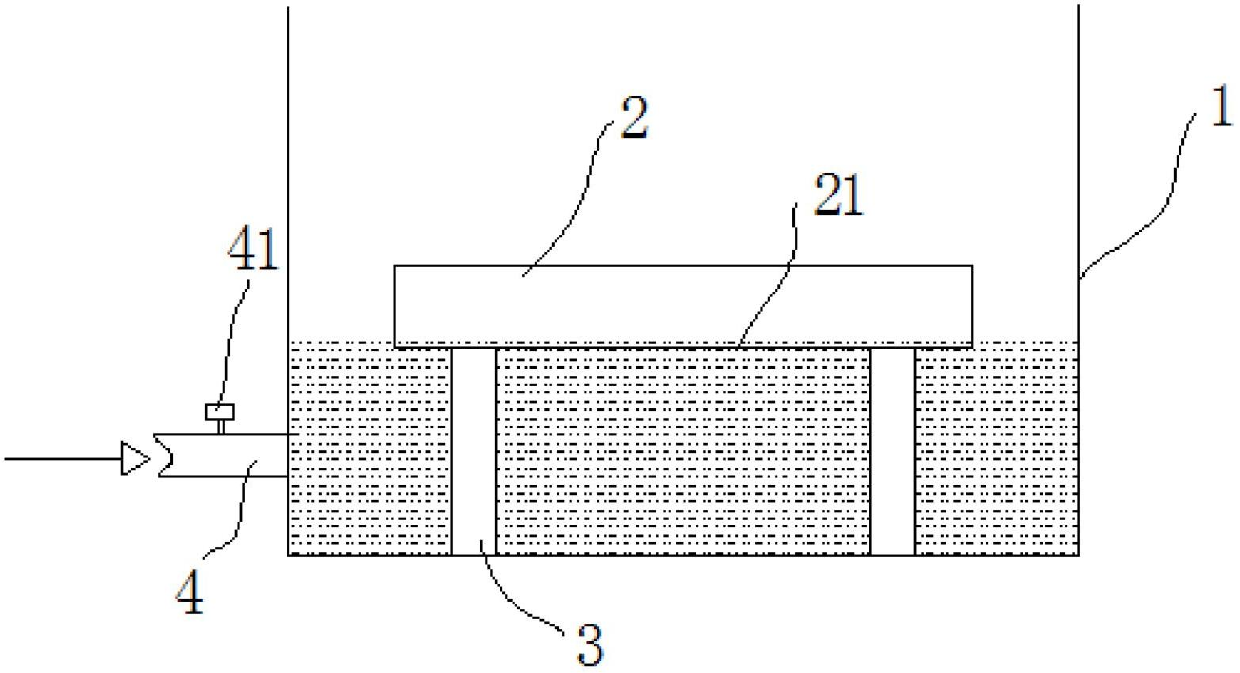

[0020] Impregnation: Immerse one surface of the dried wood after rotary cutting or sawing in the dipping tank 1 containing the medicament, and mount it on the support 3 in the dipping tank 1, and the position of the support 3 remains unchanged. A medicine pipeline 4 is arranged on the side wall of the dipping tank 1, and the medicine is delivered to the dipping tank 1 through the medicine pipeline 4, and a valve 41 is arranged on the medicine pipeline 4 for stabilizing the liquid level of the medicine. According to the different materials of the wood and the thickness of the required impregnated layer, the impregnated thickness of the floor is controlled by raising and lowering the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com