Special angle elbow manufacturing mold

A special angle and mold technology, applied in the field of molds for parts production, can solve the problems of high total cost of mold opening and manufacturing, low pass rate, etc., and achieve the effect of solving incomplete supply, low production cost, and reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

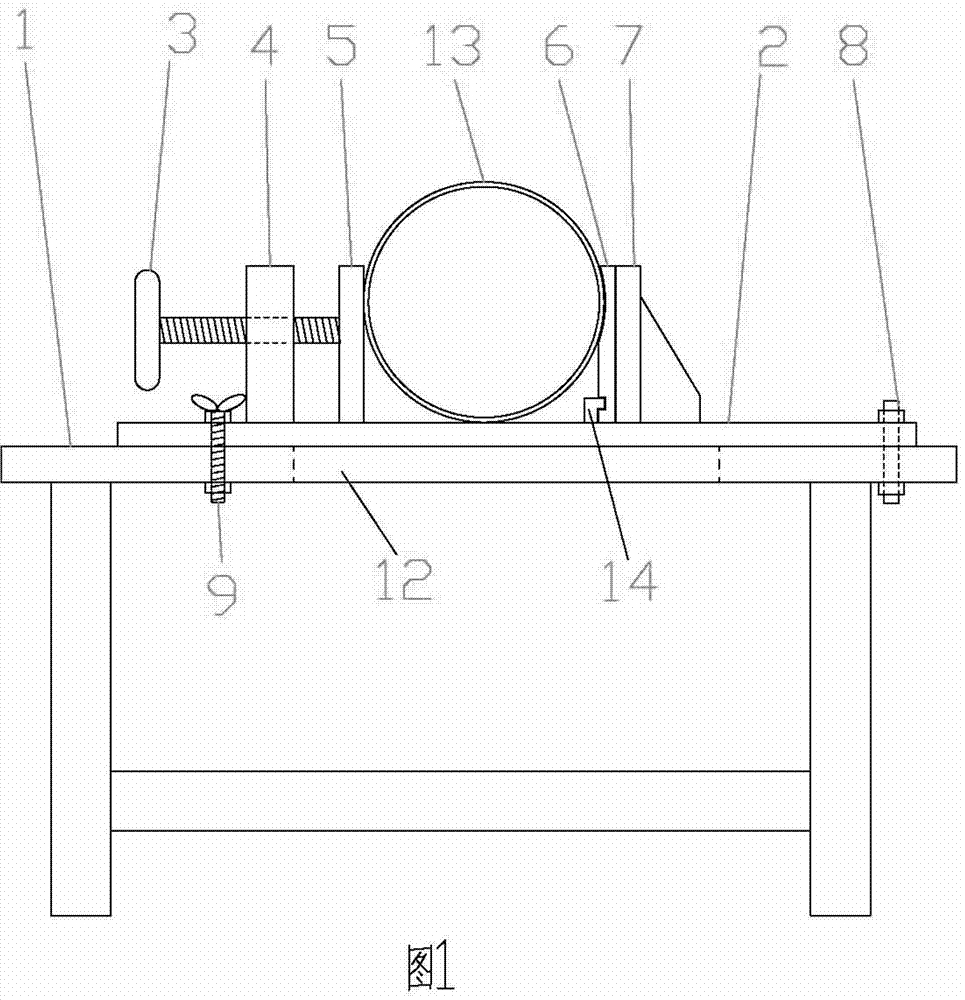

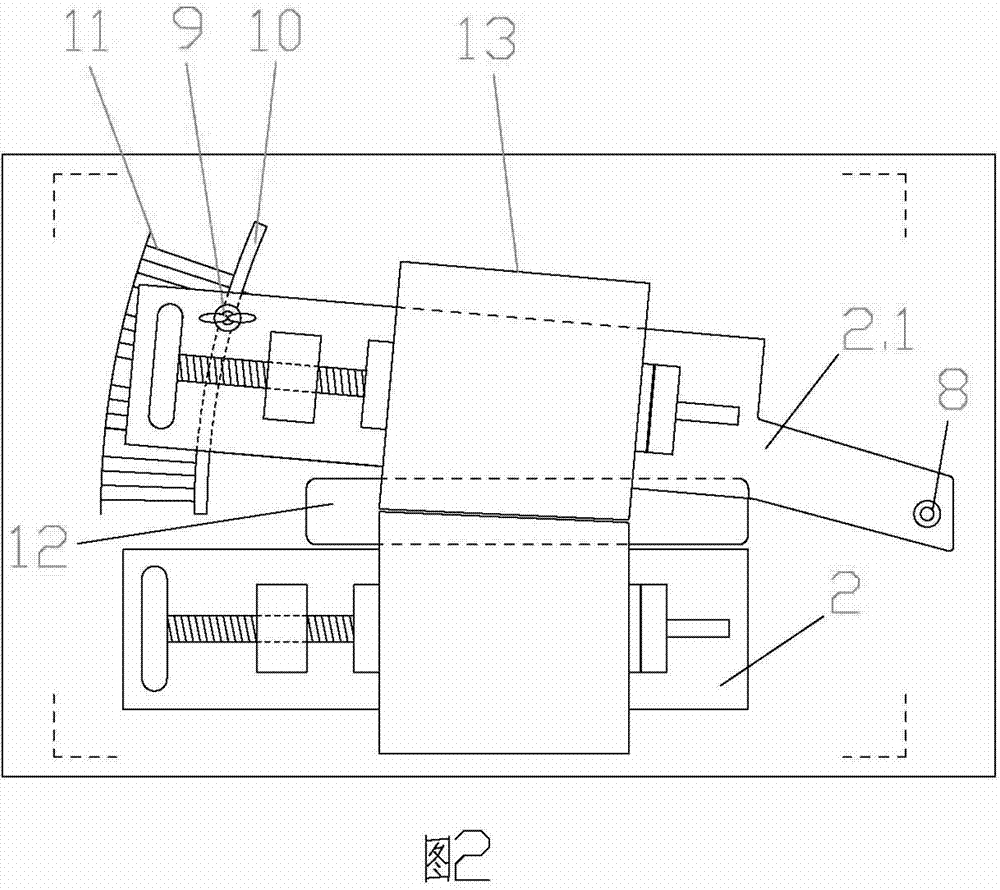

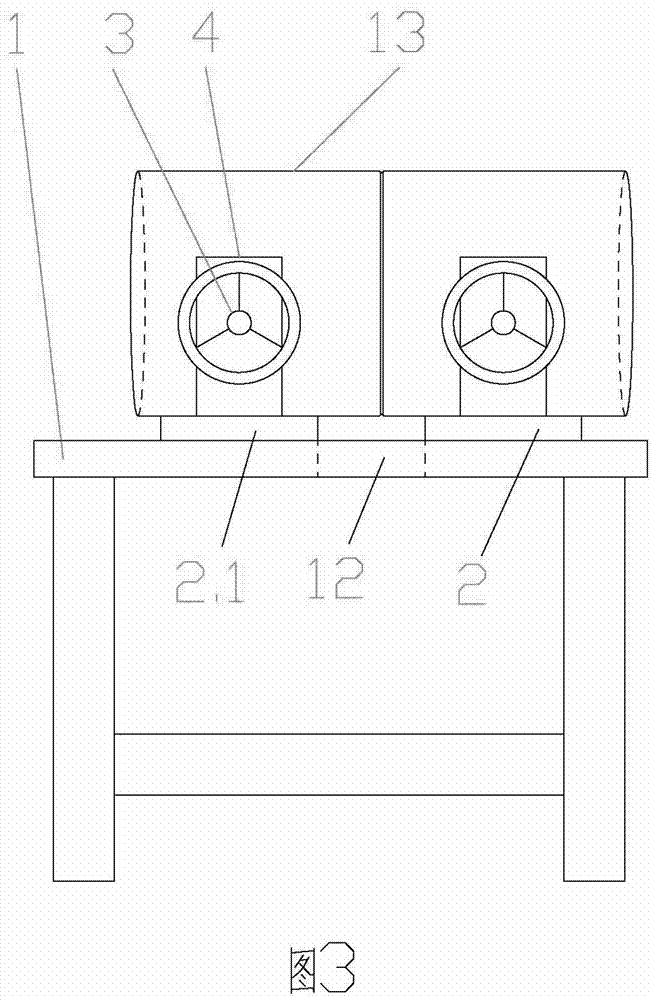

[0018] Such as figure 1 , figure 2 , image 3 As shown, the special angle elbow manufacturing mold of the present invention includes an operation table 1 . A bar-shaped welding operation hole 12 is longitudinally arranged in the middle part of the table top of the operating table 1, through which the welding operation is performed. One side of the welding operation hole 12 is fixedly connected with a fixed base 2; the front part of the other side of the welding operation hole 12 is provided with an arc-shaped butterfly bolt guide groove 10, and the outer arc edge of the butterfly bolt guide groove 10 is provided with an angle dial 11. A hinge shaft 8 is fixed at the rear, and the hinge shaft 8 is hinged to the rear of the angle adjustment base 2.1. The front part of the angle adjustment base 2.1 has a butterfly bolt 9, and the butterfly bolt 9 guides the angle adjustment base 2.1 through the guide groove 10. The front part is movably connected on the table top of the conso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com