Raschig ring and porous medium combined biologic filling

A technology of porous media and biological fillers, applied in air quality improvement, chemical/physical process, chemical/physical/physical-chemical process, etc. It can achieve the effect of reusable supporting strength, reducing energy consumption and not easy to compact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

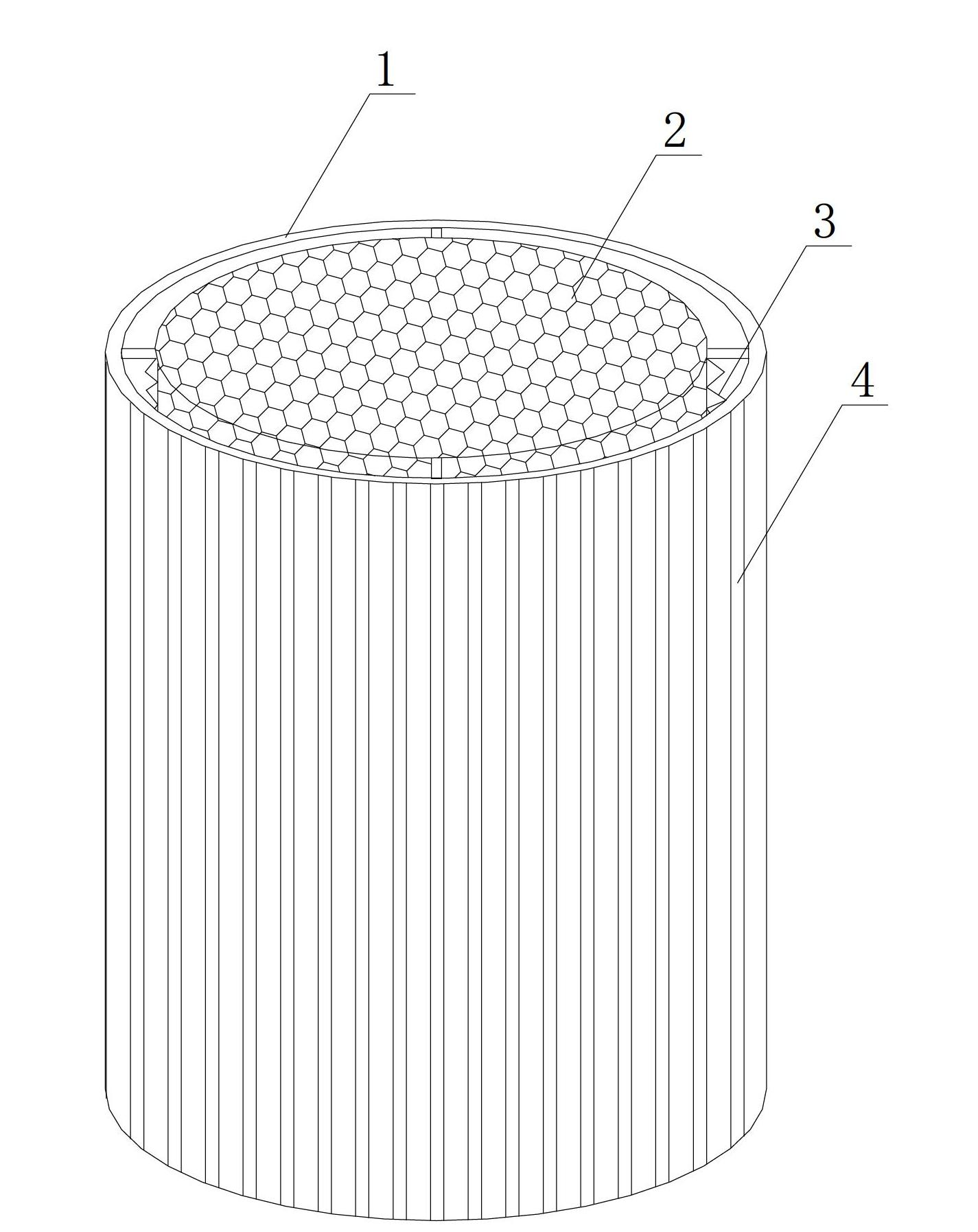

[0026] Such as figure 1 As shown, it is a combined biological filler of Raschig rings and porous media according to the present invention, including Raschig rings 1, which are fixed and filled with porous media 2, and the inner wall of Raschig rings 1 is provided with sawtooth fixing strips 3 for Secure and support porous media2. There are four sawtooth fixing strips 3, which are evenly arranged on the inner wall of the Raschig ring 1 along the axial direction of the Raschig ring 1 . The Raschig ring 1 is in the shape of a short tube, and the outer wall of the Raschig ring 1 is provided with several strip grooves 4 along the axial direction. The inner diameter of the Raschig ring 1 is 13.5mm~14.5mm, the thickness of the Raschig ring 1 is 0.5mm~2mm, and the height of the Raschig ring 1 is 14mm~16mm. The width of the strip groove 4 is 1.5mm-2.5mm, the depth of the strip groove 4 is 0.8mm-1.2mm, and the number of the strip groove 4 is 16-24. The number of cells per inch of the...

Embodiment 2

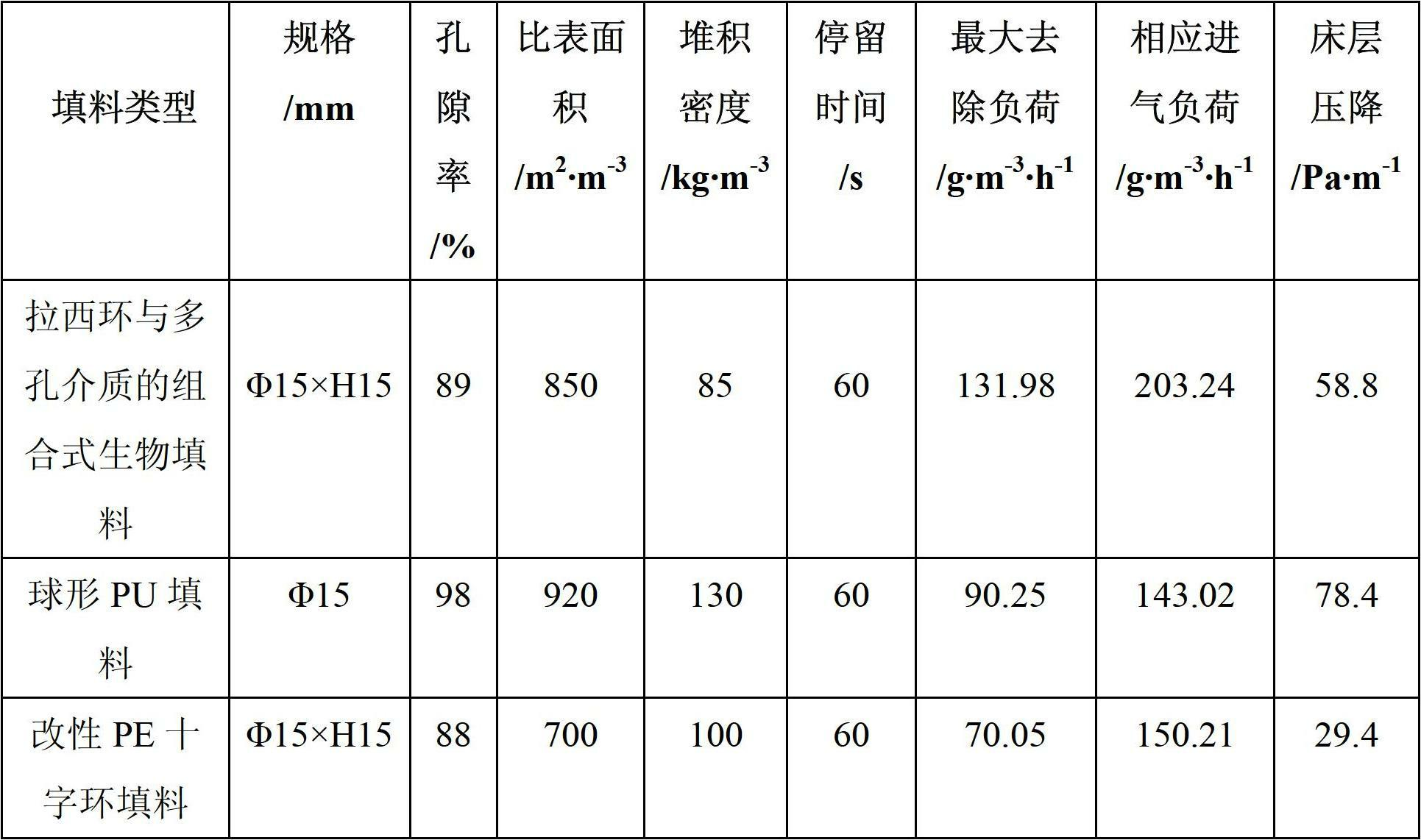

[0028]Parallel test: Establish 3 sets of plexiglass biological trickling filter towers with a height of 1000mm and a diameter of 120mm (each with 3 sets of packing layers, and the total installation height is 500mm) to study the characteristics of different types of biological packing and their paraxylene ( Xylene) comparison of the removal effect of organic waste gas. The three groups of plexiglass biological trickling filter towers are respectively equipped with the combined biological filler of Raschig ring and porous medium of the present invention, spherical polyurethane (PU) filler, modified polyethylene (PE) cross ring in Example 1. filler.

[0029] In the combined biological filler of Raschig rings and porous media of the present invention in Example 1, the inner diameter of the Raschig ring 1 is 14mm, the height of the Raschig ring 1 is 15mm, and the groove bottom of the strip groove 4 reaches the Raschig ring 1 The thickness between the inner walls of the strip groo...

Embodiment 3

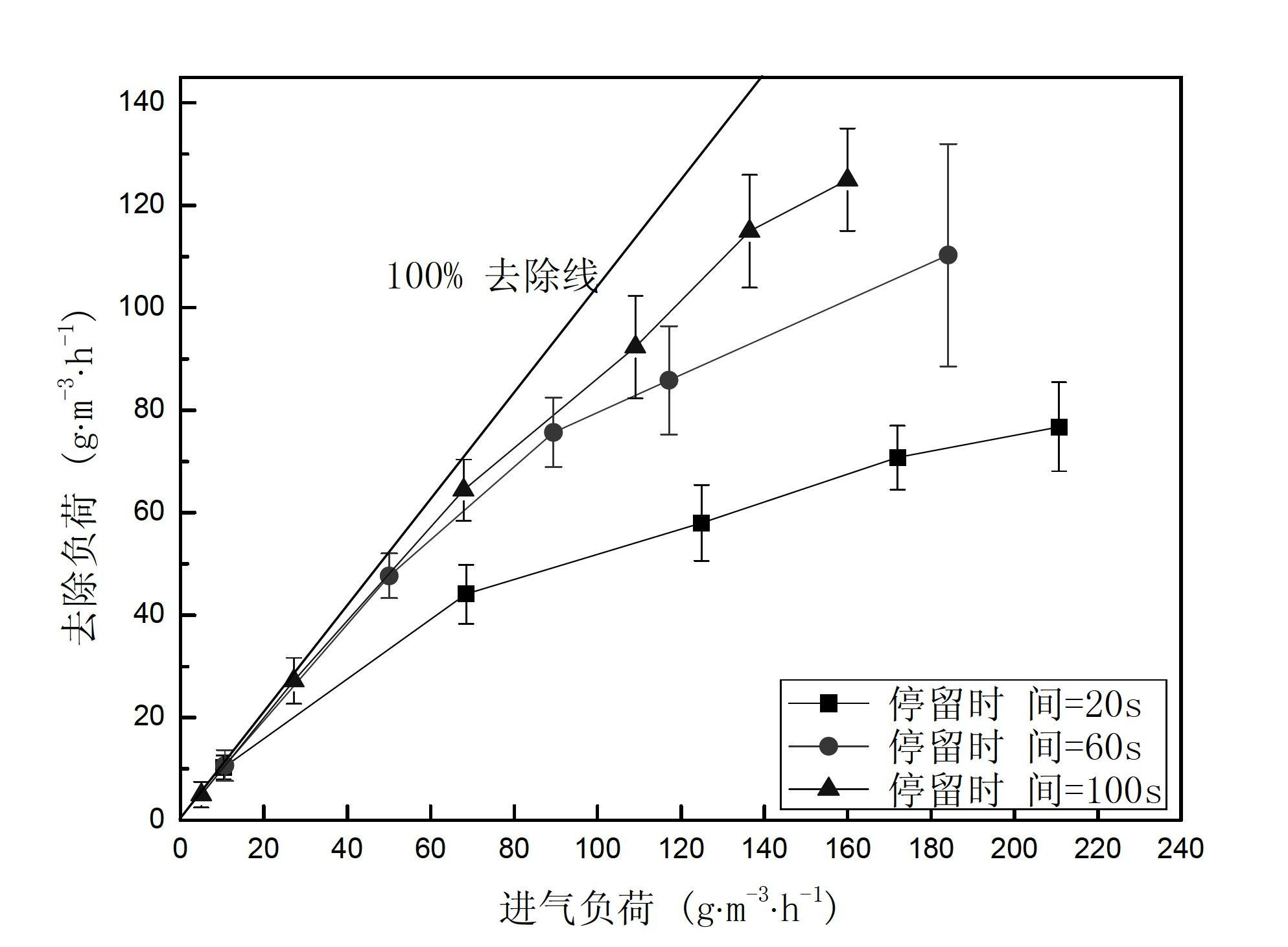

[0038] During the stable operation of the plexiglass biological trickling filter tower equipped with the combined biological filler of the Raschig ring and porous medium in Example 2, that is, after 90 days of continuous and stable operation, it was investigated at different residence times (respectively 20s, 60s, 100s), the relationship between the intake load and the removal load, and the anti-shock load capacity of the plexiglass bio-trickling filter tower was studied. The specific results are as follows figure 2 shown.

[0039] Depend on figure 2 It can be seen that the plexiglass biological trickling filter tower is under different operating conditions (the residence time EBRT is set to 20s, 60s, 100s respectively, and the corresponding treatment gas volume is 1.98m 3 / h, 0.66m 3 / h, 0.395m 3 / h) When treating xylene organic waste gas, a good removal effect has been obtained; when EBRT=60s, when the intake load is greater than 180g m -3 h -1 , the corresponding ave...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com