Section storage rack

A technology for storage racks and profiles, which is applied to storage devices, transportation and packaging, etc., can solve the problems of large storage area, low hoisting operation efficiency, hidden dangers, etc., and achieves simple production and installation, improved operating efficiency, and convenient hoisting operations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

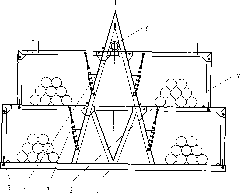

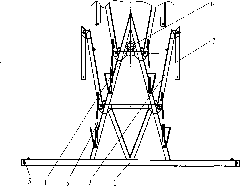

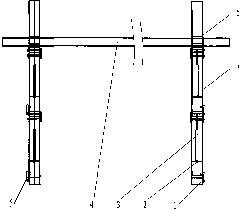

[0017] Such as Figure 1 ~ Figure 3 As shown, the profile storage rack of the present invention connects two or more storage racks in series through the connecting pipe 4 to form a storage rack group; each storage rack includes an "A"-shaped main support frame 1, a space layer support beam 2 and its legs 7 , reset gas spring 3, connecting buckle 5 and connecting sleeve 6 located on the upper part of the "A"-shaped main support frame, arranged in three layers; the space layer support beam 2 connects with the "A"-shaped main support frame 1 through one end of the pin shaft Hinged, the other end is hinged with one end of the support foot 7, the other end of the support foot 7 can be fixed or loosened with the support beam of the next layer through the connecting buckle 5, and the angle between the support beam 2 of the space layer and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com