Alcohol recovery tower

An alcohol recovery tower and alcohol technology, applied in separation methods, distillation separation, organic chemistry, etc., can solve problems such as reflux, explosion, and difficulty in controlling the temperature of the tower body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

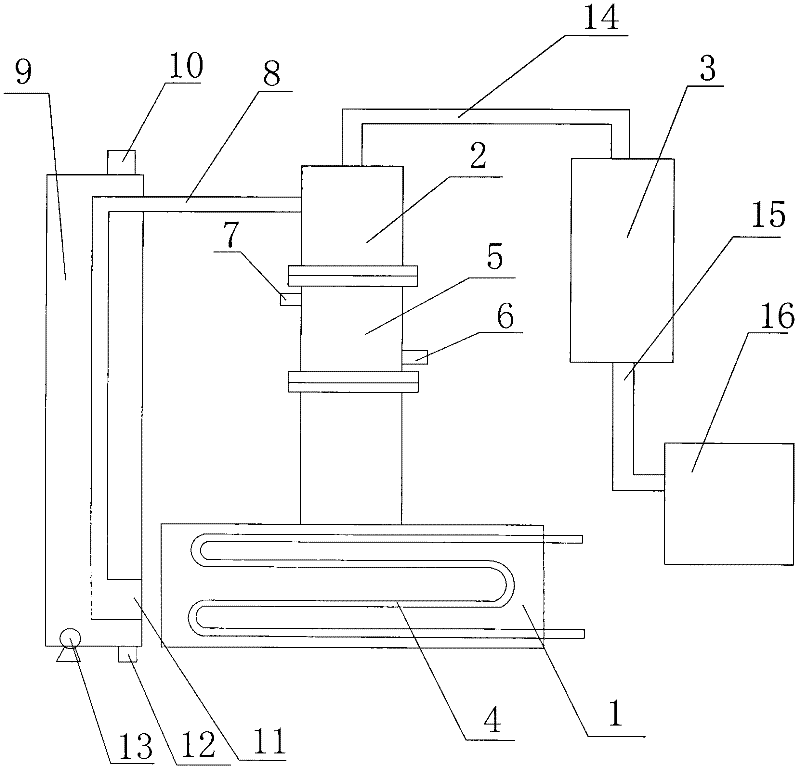

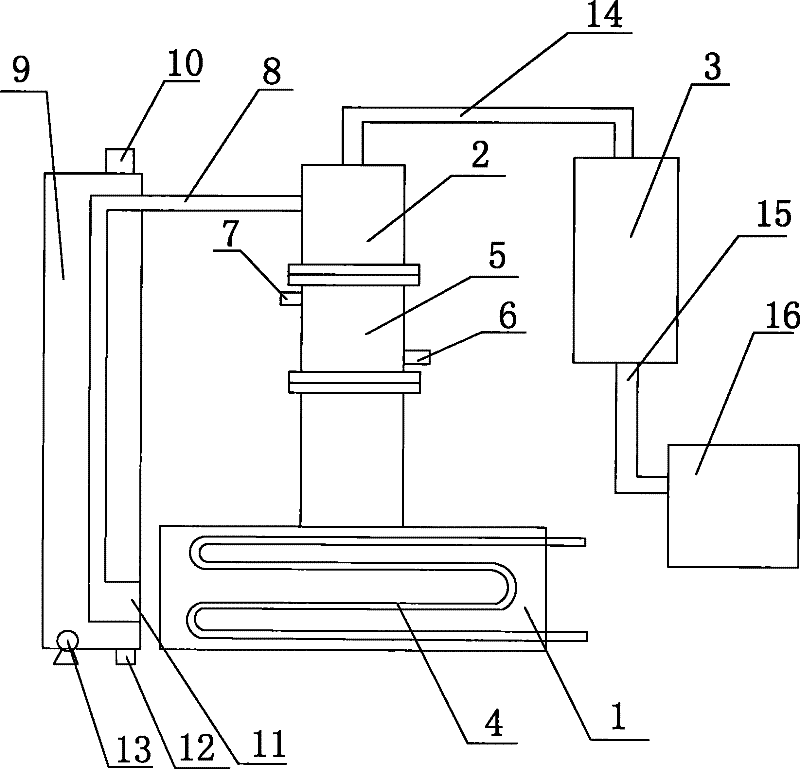

[0011] like figure 1 As shown, a kind of alcohol recovery tower of the present invention comprises tower still 1, tower body 2 and condenser 3, tower still 1 and tower body 2 are one, is provided with heating tube 4 in tower still 1, and tower body 2 is equipped with Temperature control tower section 5, one side of the lower part of the temperature control tower section 5 is provided with a cooling water inlet 6, the other side of the upper part of the temperature control tower section 5 is provided with a cooling water outlet 7, the upper part of the tower body 2 passes through the cooling water pipe 8 and the alcohol preheating chamber 9 connection, the top of the alcohol preheating chamber 9 is provided with a cooling water inlet 10, the bottom side of the alcohol preheating chamber 9 is provided with an alcohol inlet 11, the bottom of the alcohol preheating chamber 9 is provided with a circulating water outlet 12, and the circulating water outlet 12 is provided with Circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com