Chemotherapy drug pulse sustained-release implant agent and preparation method thereof

A technology for slow-release implants and chemotherapeutic drugs, applied in drug combinations, pharmaceutical formulations, anti-tumor drugs, etc., can solve the problems of re-administration, application restrictions, and drugs can only be released once, so as to avoid side damage and prolong Effect of Effective Drug Concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

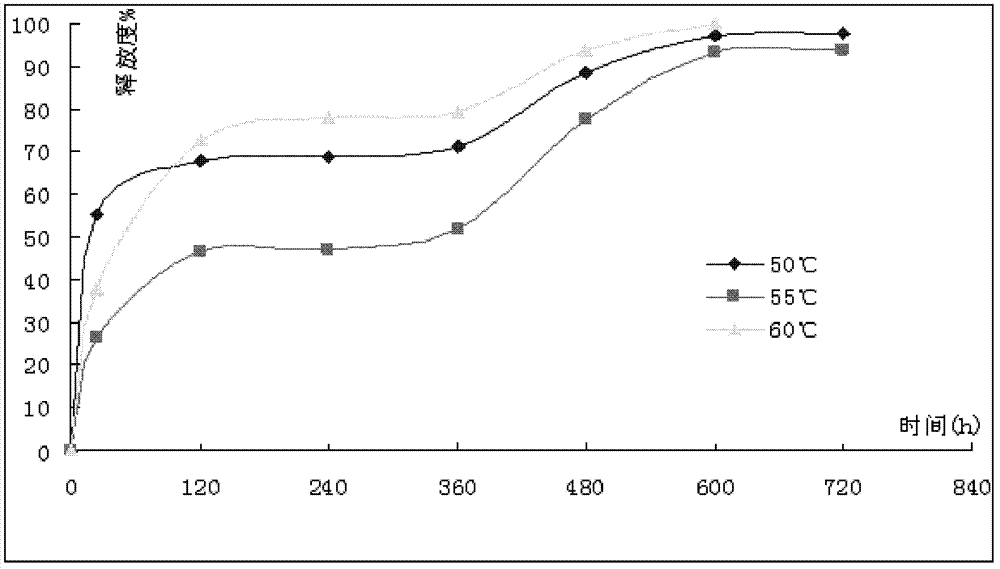

[0025] Embodiment 1, preparation of gemcitabine hydrochloride microspheres

[0026] Pulverize gemcitabine hydrochloride, pass through a 200-mesh sieve, add PLGA (the number average molecular weight is 6000) in dichloromethane solution (the mass-number ratio of gemcitabine hydrochloride and PLGA is 1:9), stir evenly, evaporate the solvent to dryness, and place in a vacuum Dry in a drying oven (-0.1Mpa, 35°C) for 4 hours, take it out and crush it through an 80-mesh sieve, and then dry it for 24 hours, take out the medicinal material, mix it in a melting and mixing equipment with a constant temperature of 120°C, cool it, and crush it. Sieve, take microspheres between 100 mesh and 120 mesh sieves, and process them with a microsphere processor at 55° C. for 10 minutes to obtain gemcitabine hydrochloride microspheres, marked as sample A.

[0027] Gemcitabine hydrochloride microspheres were prepared according to the same method as above, labeled as sample B and sample C, respectively...

Embodiment 2

[0060] Embodiment 2, preparation of gemcitabine hydrochloride microspheres

[0061] Gemcitabine hydrochloride microspheres were prepared according to the same method as in Example 1, except that the melting and kneading temperatures were 110° C. and 130° C. respectively, and the prepared microspheres were marked as sample D and sample E, respectively.

[0062] The stability of gemcitabine hydrochloride was investigated at 110°C, 120°C, and 130°C when melted and kneaded, and the detection index was related substances of gemcitabine hydrochloride. The results are shown in Table 4.

[0063] Table 4 Limits of related substances of samples D, A and E

[0064]

[0065] It can be seen from Table 4 that gemcitabine hydrochloride is stable when the melting and kneading temperature is 110°C to 130°C, and the preferred melting and kneading temperature is 120°C.

Embodiment 3

[0066] Embodiment 3, preparation of gemcitabine hydrochloride microspheres

[0067] Gemcitabine hydrochloride microspheres were prepared according to the same method as in Example 1, except that the microspheres were passed through sieves of 80-100 mesh and 120-150 mesh respectively, and the prepared microspheres were respectively marked as sample F and sample G.

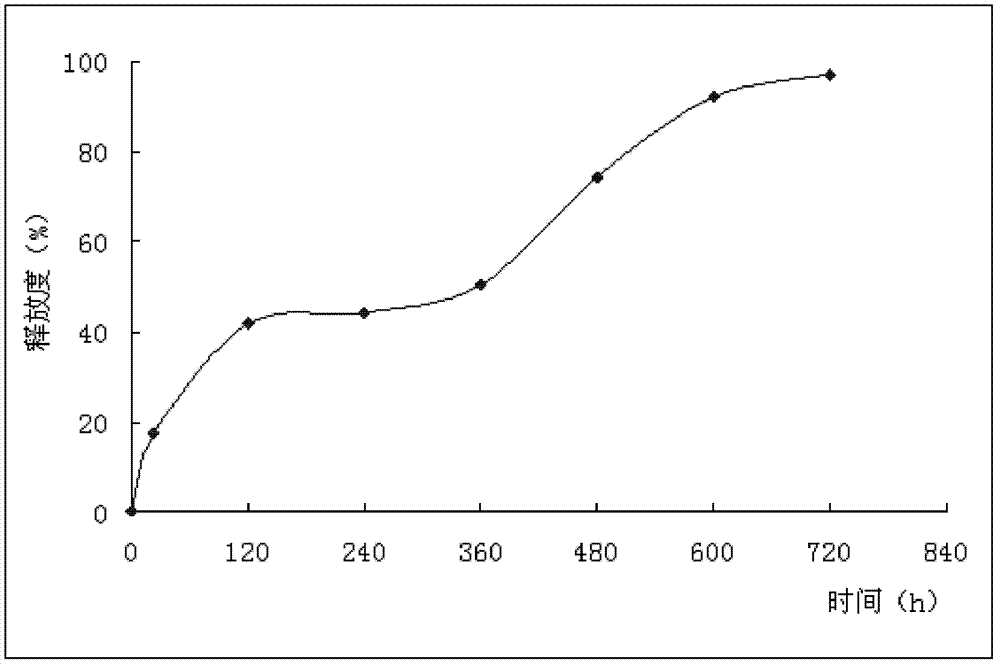

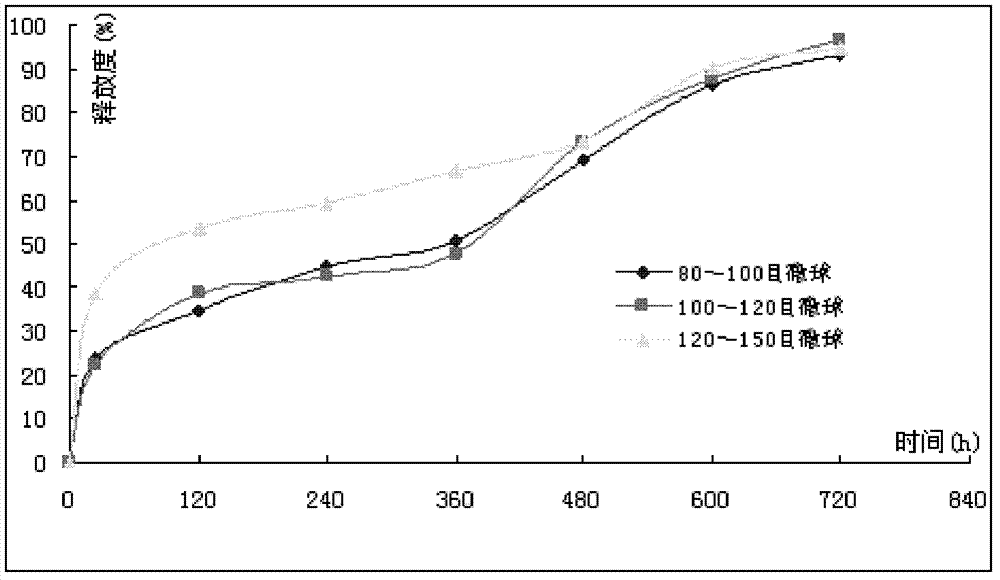

[0068] Detect the in vitro release of samples A, F and G, the results are shown in Table 5 and figure 2 .

[0069] Table 5 The relationship between the in vitro release rate and time of samples A, F and G

[0070]

[0071] From Table 5 and figure 2 It can be seen that the particle size of the microspheres is between 80-100 mesh sieve and 100-120 mesh sieve, and the release rate of gemcitabine hydrochloride microspheres in vitro can meet the project design requirements. When considering clinical application, the smaller the particle size, the more convenient, preferably 100-120 mesh Microspheres between sieve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com