Cyclone separating device for reducing anticyclone

A technology of cyclone separation device and cyclone separator, which is applied in suction filters and other directions, can solve the problems of reducing dust separation efficiency, difficulty in dust collection, and reducing air flow speed, and achieve the effect of ensuring suction power, fast air flow speed and reducing leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the drawings and embodiments. In the present invention, the same components as in the prior art use the same symbols.

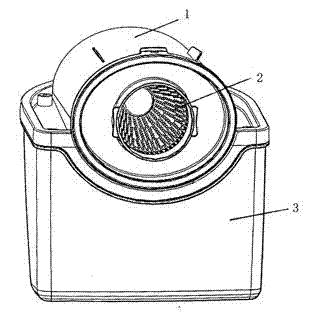

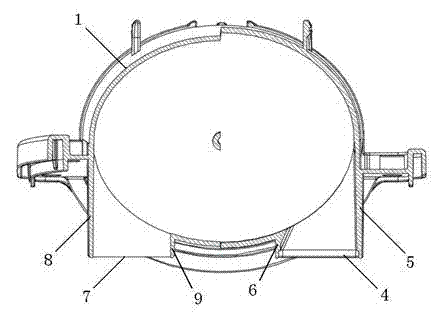

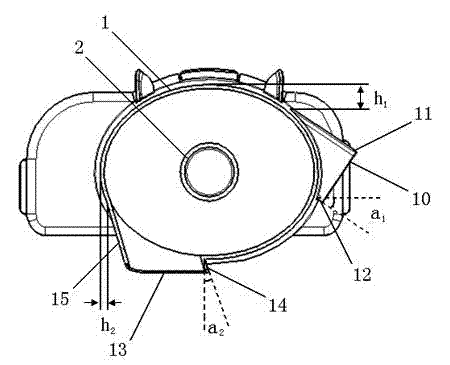

[0031] The cyclone separation device of the present invention is arranged in the dust collection device, and the dust collection device includes a dust collection bucket, a cyclone separator, and a filter horizontally installed inside the barrel of the cyclone separator. The back end of the cyclone is closed and the front end is open. An air inlet is formed on the front wall of the barrel of the cyclone separator, and the rear end of the lower barrel wall of the cyclone barrel is provided with a dust outlet; the front end of the filter forms a dust outlet. A cylinder on the same center line as the filter is arranged on the inner side of the closed end of the cyclone separator.

[0032] When the suction fan of the vacuum cleaner is working, the dust near the suction head and the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com