Cgi cast iron and a production method for the same

A manufacturing method and cast iron technology, applied in the field of hypereutectic CGI cast iron, can solve the problems of poor casting and poor CGI cast iron material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10 and comparative example 1-10

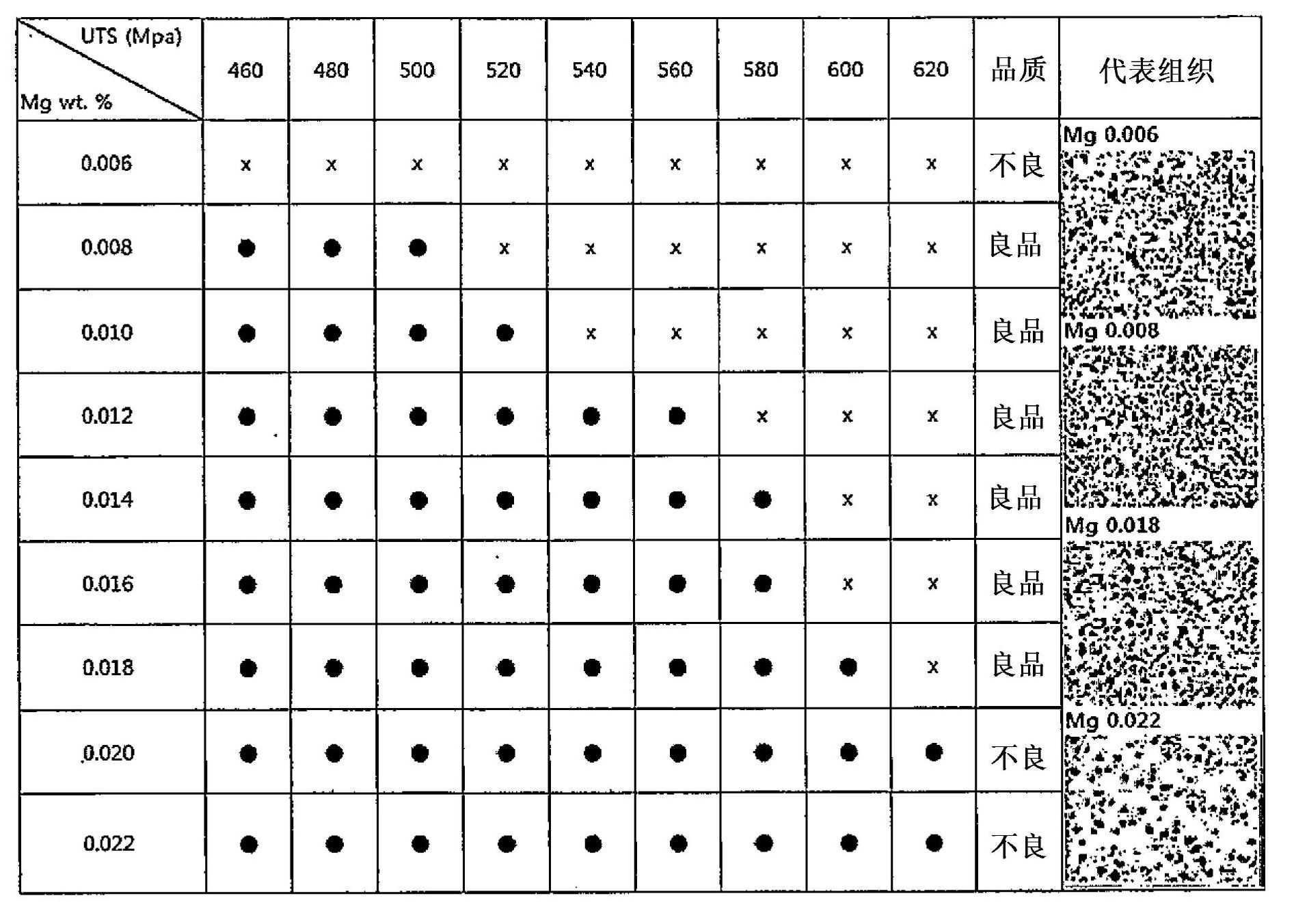

[0081] According to the composition of Table 1 below, cast irons of Examples 1-10 and Comparative Examples 1-10 were produced.

[0082] Table 1

[0083] unit weight%

[0084] differentiate

C

Si

mn

Cu

sn

Mg

P

S

Fe

Example 1

3.650

2.240

0.440

1.360

0.090

0.017

0.031

trace

remaining

Example 2

3.680

2.190

0.400

1.340

0.090

0.010

0.031

trace

remaining

Example 3

3.700

2.110

0.390

1.410

0.080

0.011

0.031

trace

remaining

Example 4

3.710

2.080

0.400

1.330

0.100

0.009

0.034

trace

remaining

Example 5

3.680

2.140

0.380

1.260

0.080

0.011

0.031

trace

remaining

Example 6

3.680

2.180

0.430

1.340

0.090

0.018

0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com