Nondestructive detection system

A non-destructive testing, wall technology, applied in the direction of measuring devices, instruments, conveyors, etc., can solve the problems of poor control of manual rotation angle, labor and material resources consumption, and low detection efficiency, so as to increase the detection efficiency range, improve detection efficiency, and save manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. In addition, it should be understood that after reading the content taught by the present invention, those skilled in the art can make various changes or modifications to the present invention. Equivalent forms also fall within the scope defined by the appended claims of the application.

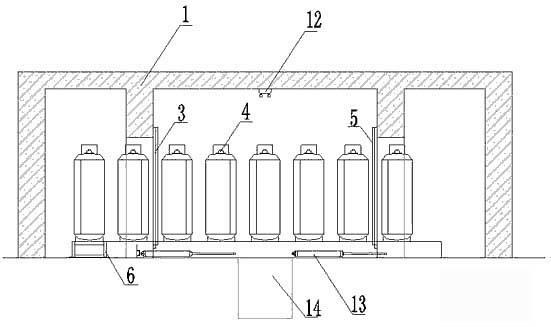

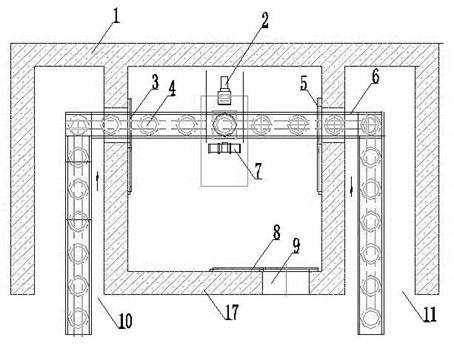

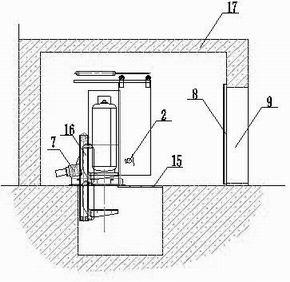

[0029] Such as figure 1 , figure 2 , image 3 As shown, a non-destructive testing system of the present invention has a structural schematic diagram, a plane top view and a left sectional view, and is composed of a conveying device, a swing device, a turntable and auxiliary parts. Groove shape, a square inner wall 17 is arranged in the middle of the outer wall 1, and an entry channel 10 and a removal channel 11 are arranged between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com