Mechanical soil-sampling device

A mechanical, soil sampling technology, applied in the direction of sampling devices, etc., can solve the problems of poor applicability, complex structure, low efficiency, etc., and achieve the effects of high mechanical efficiency, reliable operation, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

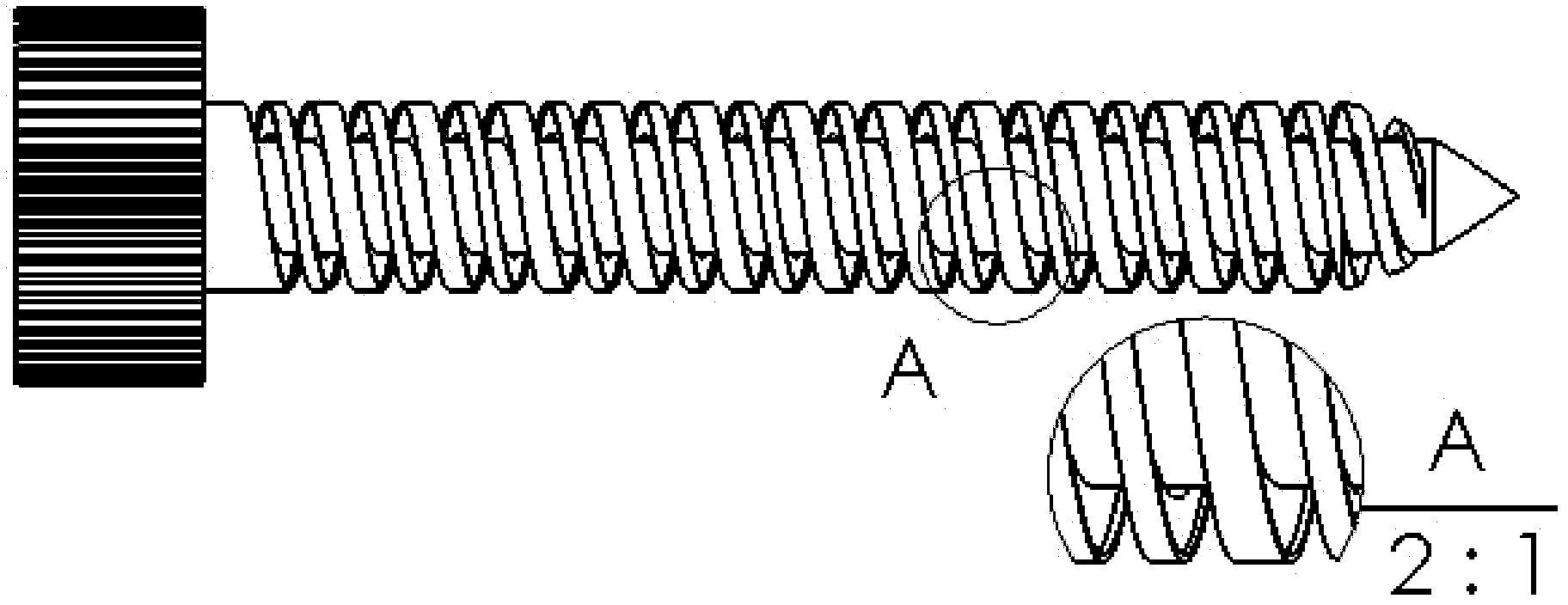

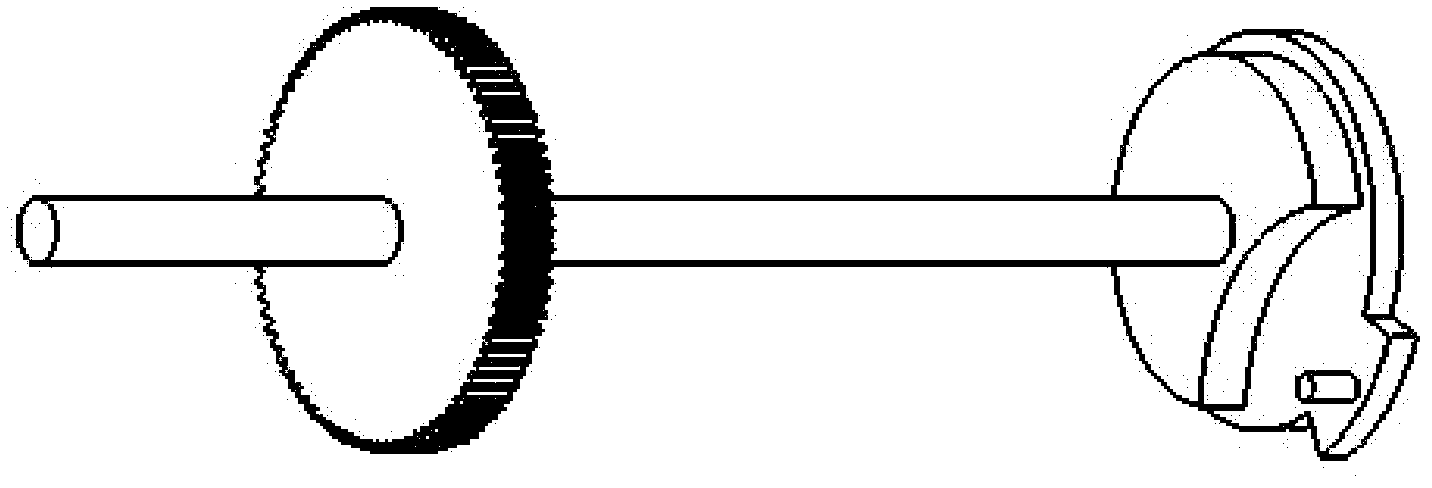

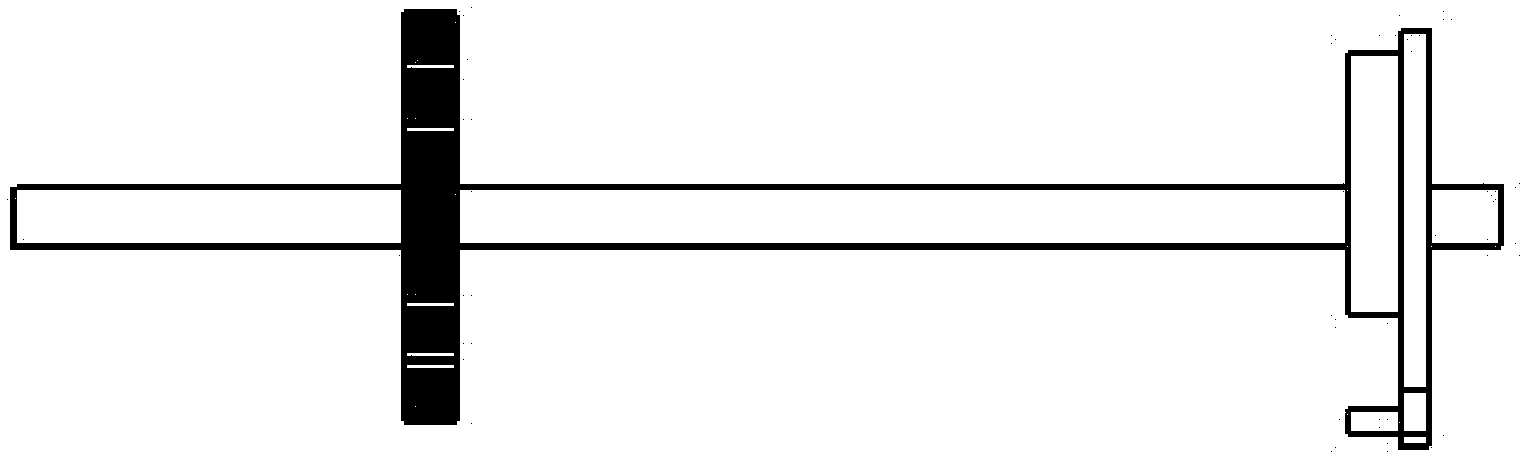

[0033] refer to Figure 1~Figure 16 , The soil sampling device consists of a box, a soil sampling drill, a motor, a reduction device, a soil sampling disc, a disc chassis, a grooved wheel mechanism, a ratchet mechanism and a rack and pinion mechanism. The lower end of the soil sampling drill is made into a pointed round head, and a long special spiral inner groove is arranged above the tip of the groove sampling drill. The structure diagram of the soil sampling drill is as follows figure 1 shown. The upper end of the soil sampling drill is provided with an involute spur gear, i.e. a drive spur gear 9. The teeth of the drive spur gear 9 are thicker, and are used in conjunction with the passive spur gear 12 on the drive dial. The upper end surface of the driving spur gear 9 has a reduction device shaft hole, which cooperates with the output shaft of the first reduction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com