Characteristic extracting method for prediction of rotating mechanical failure trend

A technology of trend prediction and feature extraction, which is used in the testing of machines/structural components, measuring devices, and measuring ultrasonic/sonic/infrasonic waves. and other problems, to achieve the effect of improving the recognition ability and suppressing the interference information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

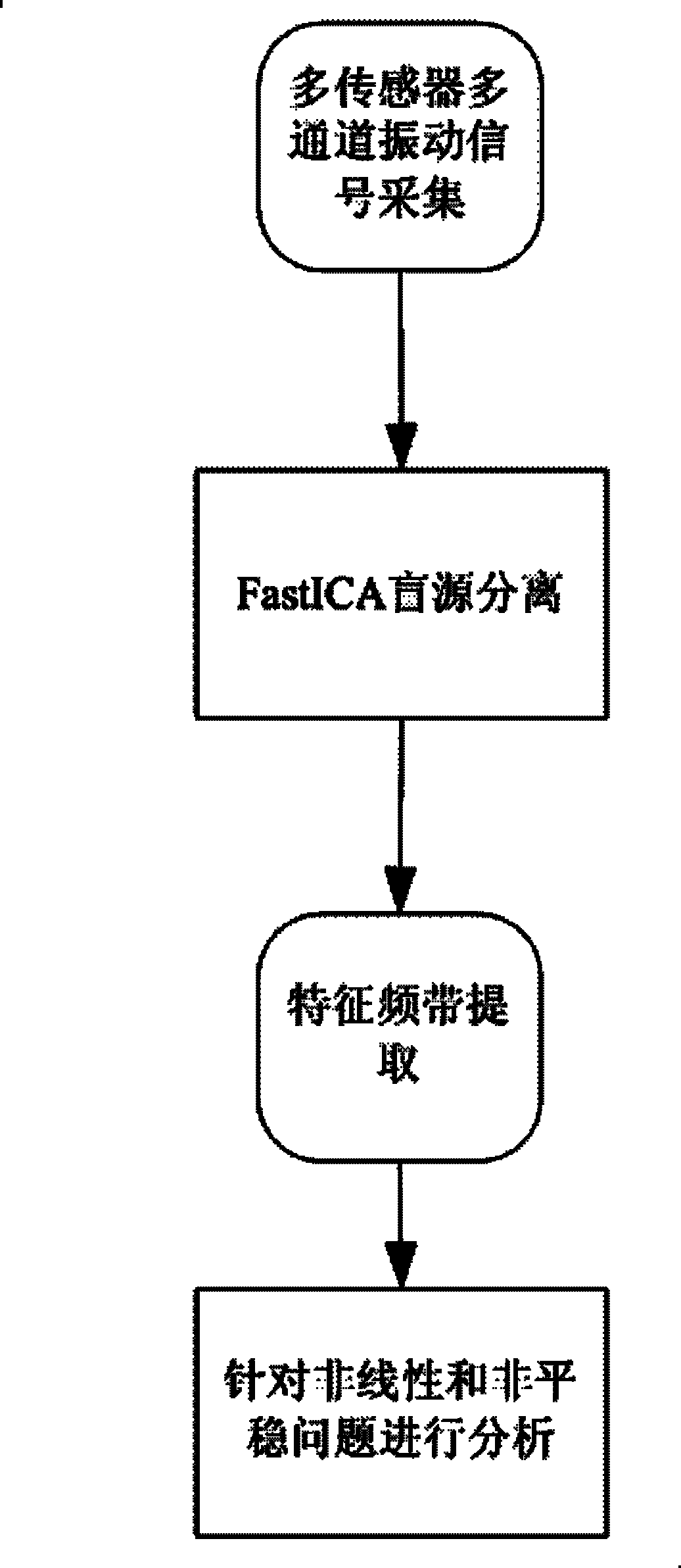

[0014] The feature extraction method for fault trend prediction of rotating machinery provided by the present invention aims at fault trend prediction, through ICA processing, from the aliased vibration signals collected by each sensor and generated by mixing multiple independent vibration signal sources, identify For each independent vibration signal source, the characteristic frequency band based on the wavelet packet is obtained for the identified independent signal source, and then it is judged whether an independent signal source is developing in the direction of failure, so as to achieve the purpose of preventing failure in advance. Such as figure 1 Shown, the present invention comprises the following steps:

[0015] (1) Use the existing remote online monitoring and diagnosis center to collect industrial field data, and collect vibration signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com