Integrated electric contact liquid level and liquid temperature measurement sensor

A technology for measuring sensors and electrical contacts, which is applied in the field of liquid level and temperature measuring devices for high-temperature and high-pressure containers, and can solve problems such as the easy reduction of the insulation value of signal cables, the reduction of the insulation effect of the insulation layer, and serious water chemical corrosion, etc., to reduce the measurement Blind zone, small measurement error, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

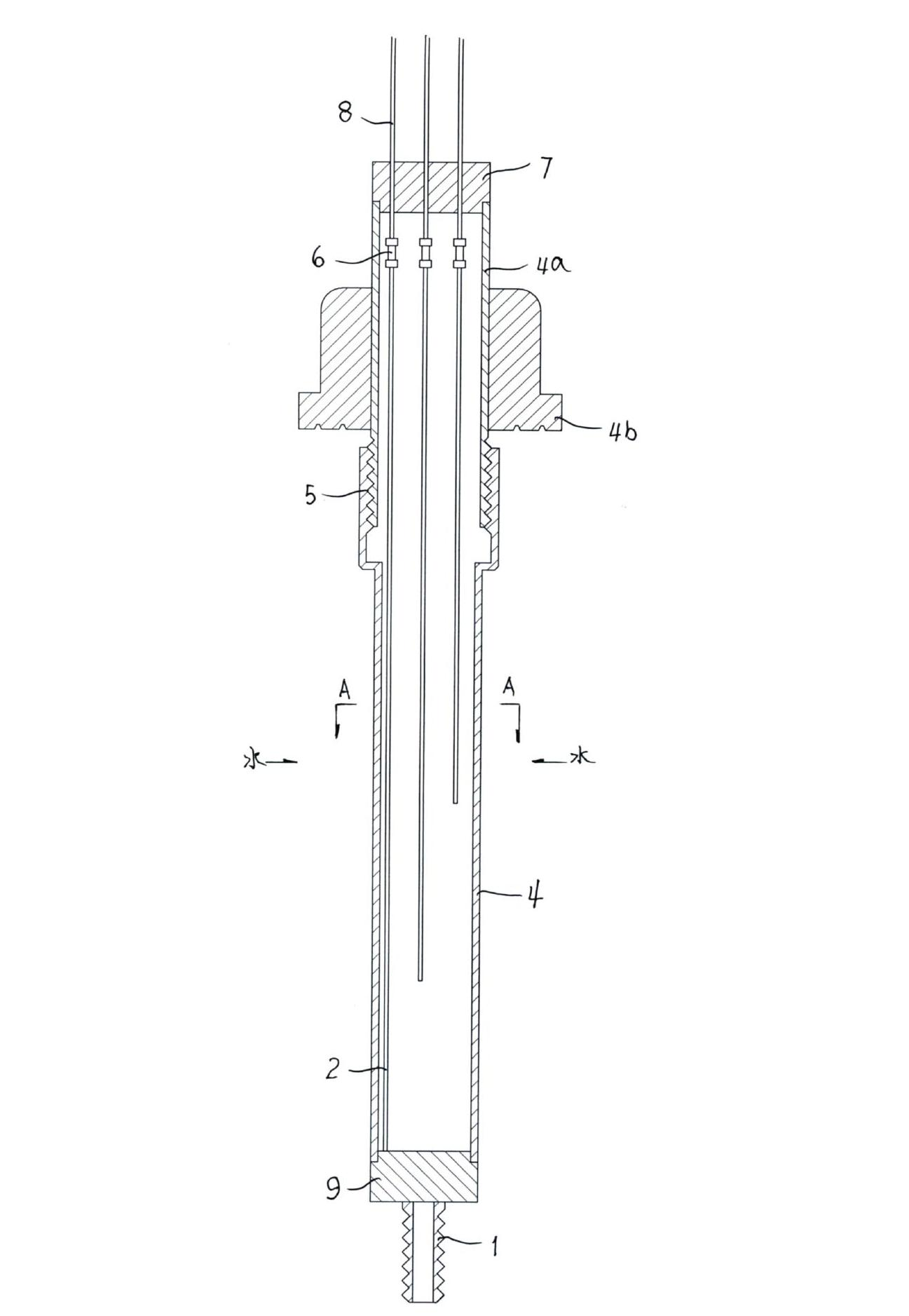

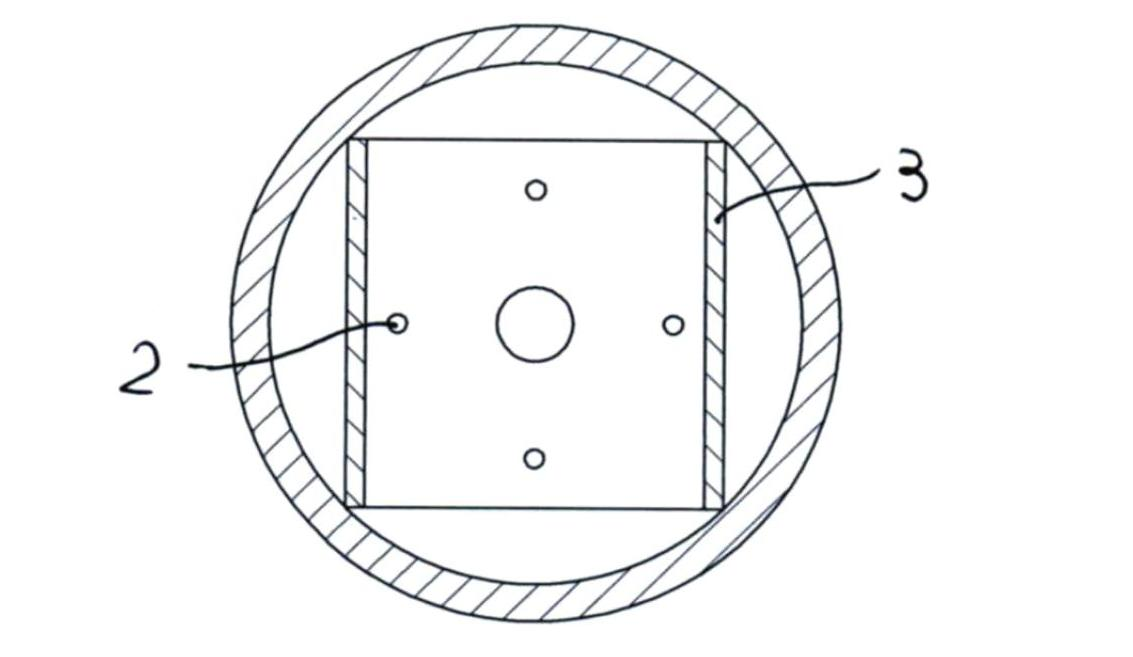

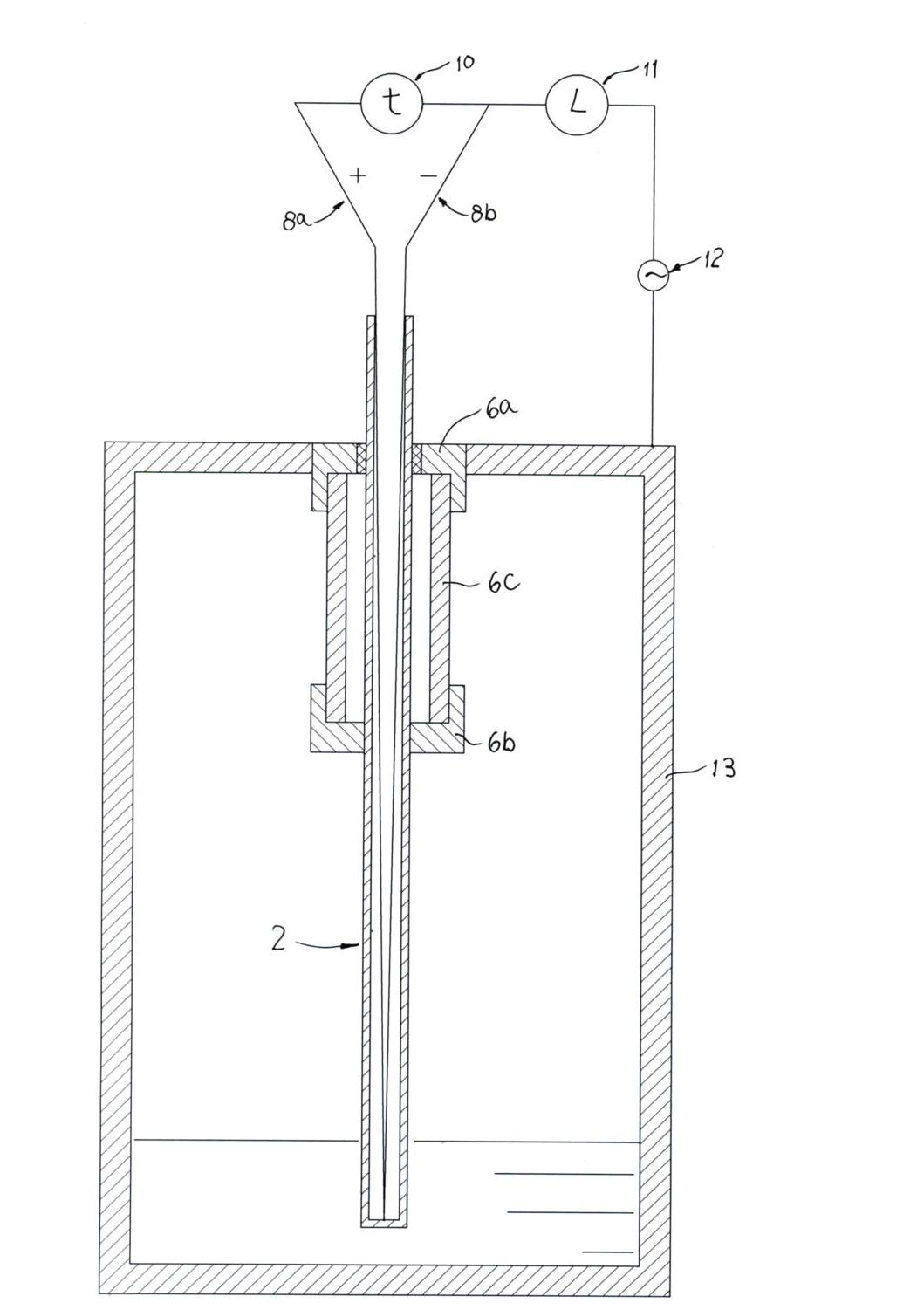

[0025] figure 1 It shows the integrated electric contact liquid level liquid temperature measurement sensor, the upper expansion section of the stainless steel protective sleeve 4 (the expansion section of the protective sleeve has an internal thread 5) is screwed on the outer surface of the upper sleeve 4a, and the upper sleeve 4a is connected to the outer surface of the upper sleeve 4a. The mounting nut or flange 4b is welded, and the upper end is provided with an upper sealing end cover 7, and a plurality of water inlet holes are provided on the stainless steel protective sleeve 4, and the skeleton 3 for installing the electrode 2 is placed inside the stainless steel protective sleeve 4, and the electrode 2 In order to arrange multiple armored thermocouple electrodes with different depths in the stainless steel protective sleeve, each armored thermocouple electrode is provided with an electrical contact 6, and all electrical contacts are located in the upper sleeve 4a;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com