Lamp fitting construction members and ceiling lamp using same

A technology of lamps and components, which is applied to the parts of lighting devices, lighting devices, fixed lighting devices, etc., can solve problems that affect the stability and appreciation of lamps, parts fall off, and the danger is self-evident, etc., to achieve lighting environment Soft and layered, reducing production and assembly costs, avoiding dark shadows and light spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Below in conjunction with embodiment the present invention is described in further detail:

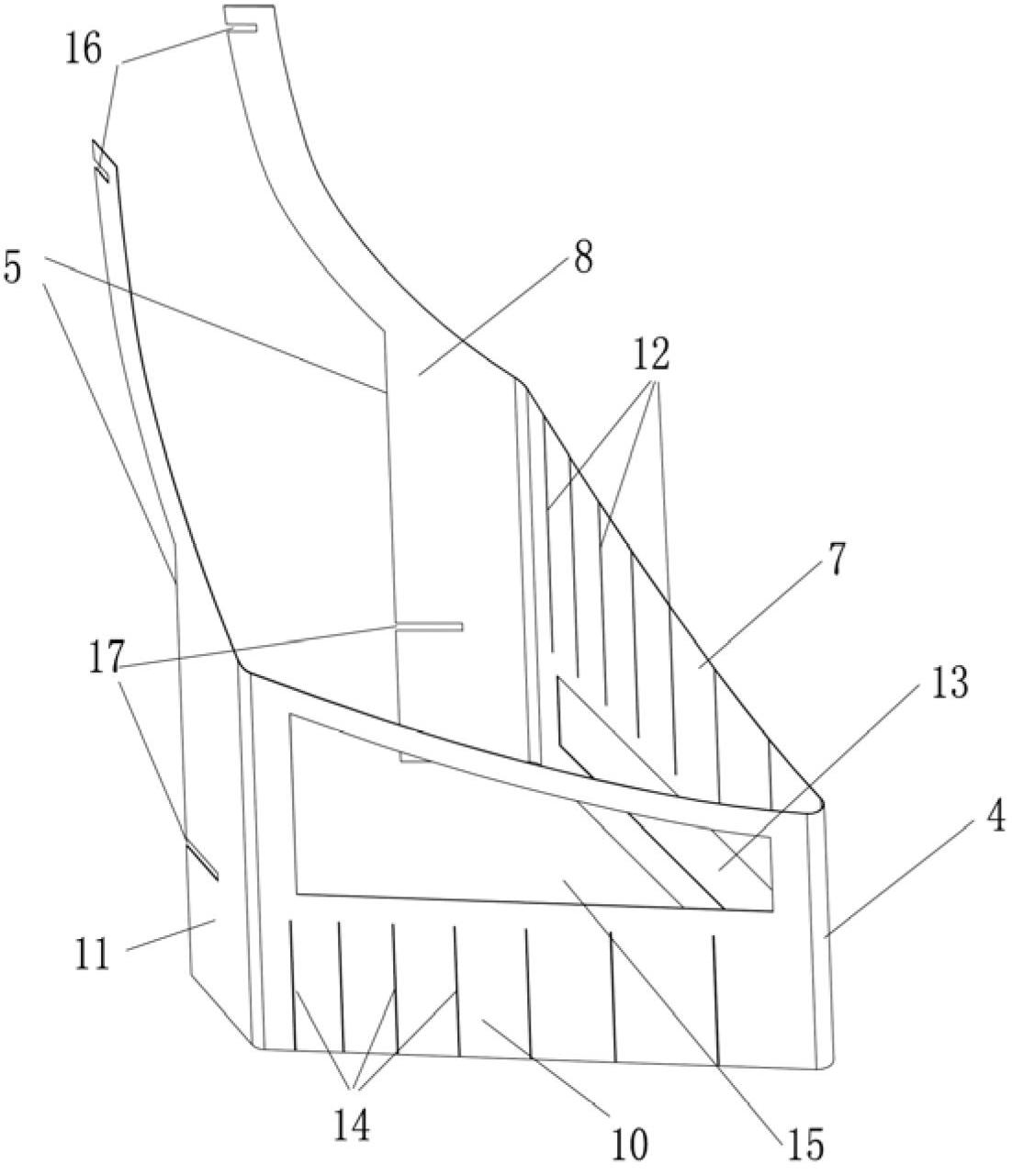

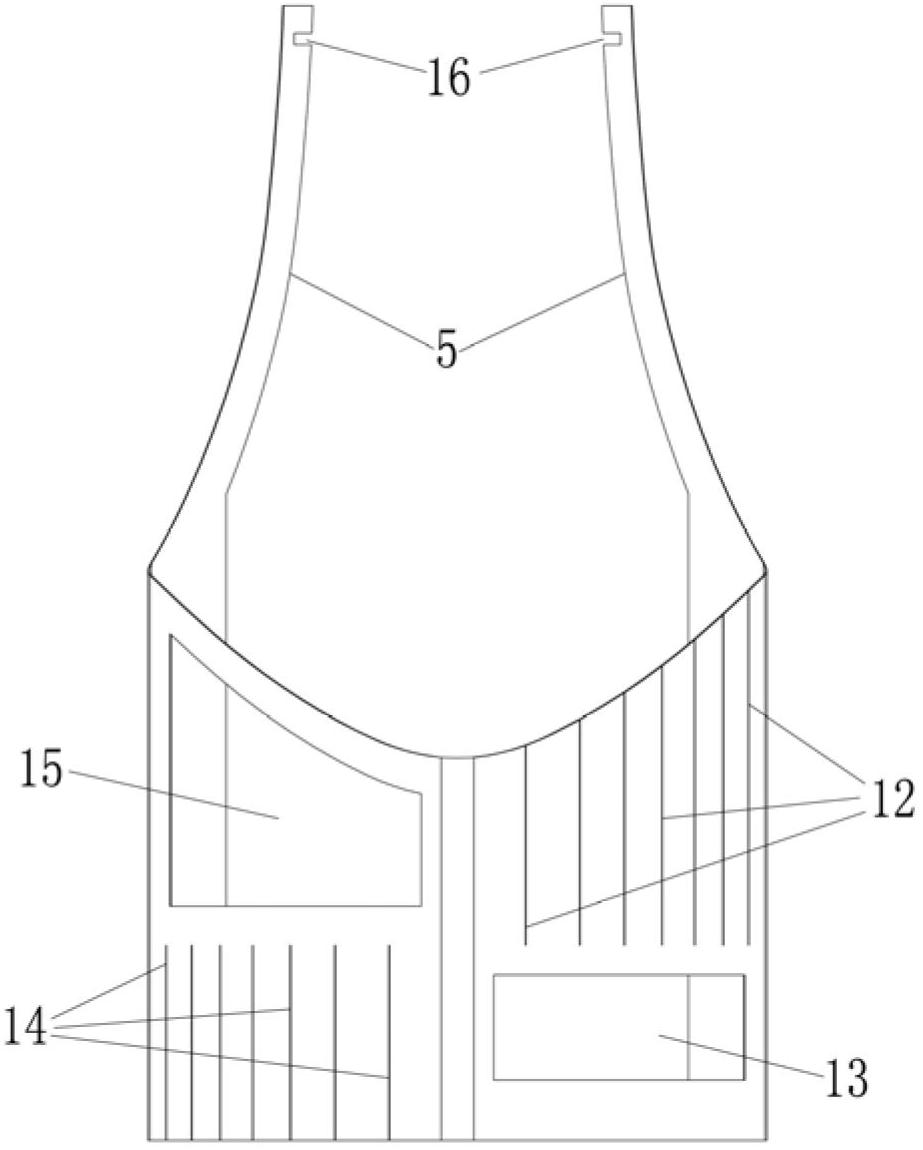

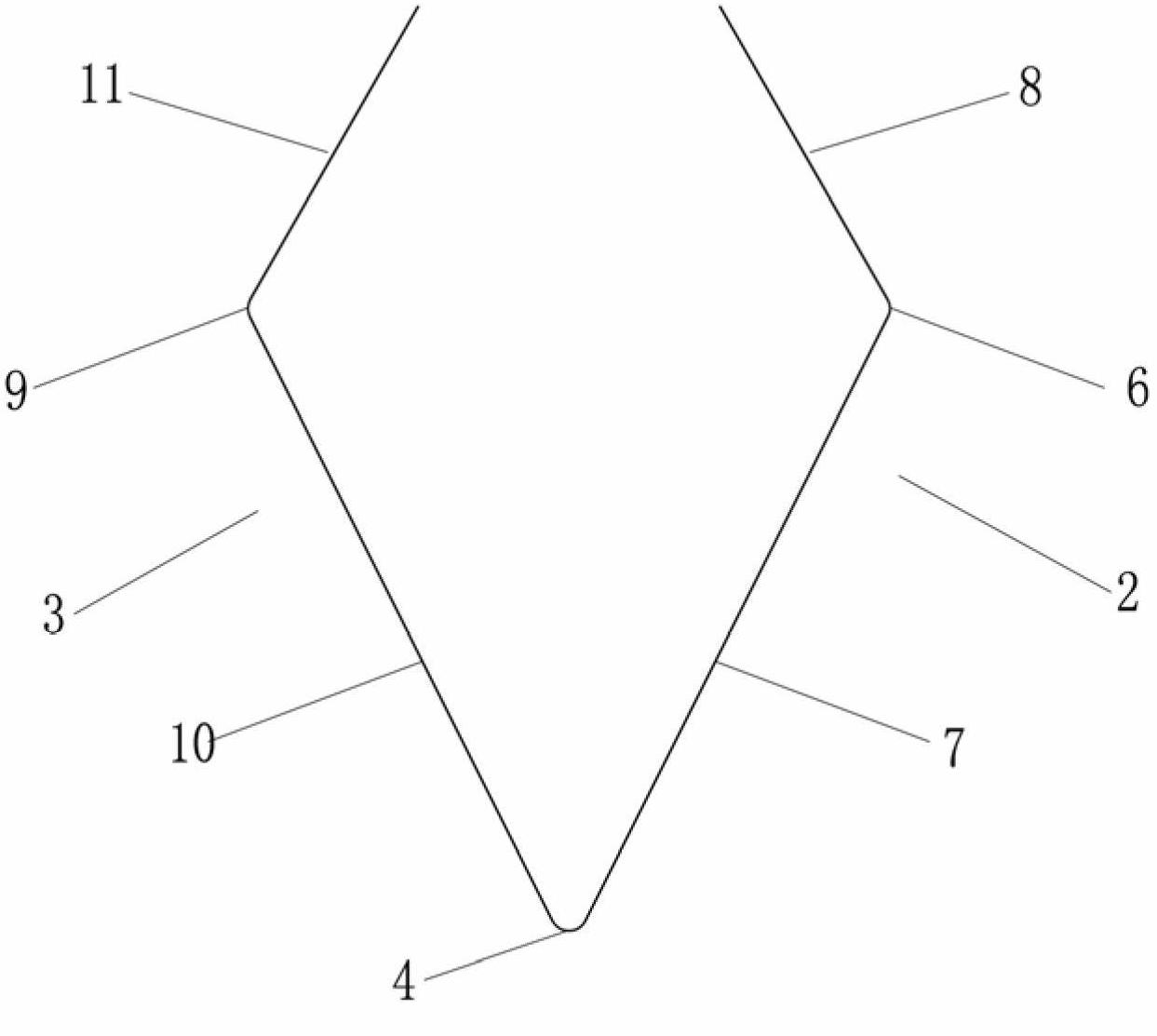

[0059] A lamp component 1, which includes a front half page 2 and a reverse half page 3 and a common edge 4 connecting the front half page 2 and the reverse half page 3, the front half page 2 and the reverse half page 3 are folded in half along the common edge 4, and the front half Page 2 and reverse half page 3 respectively form a free edge 5 away from the common edge 4, and positive half page 2 and reverse half page 3 form an opening between the two free edges 5;

[0060] The front half page 2 and the reverse half page 3 each also include an upper edge and a lower edge connecting the common side 4 and the free side 5;

[0061] The upper edges of the positive half page 2 and the reverse half page 3 extend downward along an arc from the tops of the respective free edges 5 to the top of the common edge 4; the lower edges of the positive half page and the reverse half page extend ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com