Magnesium jade porcelain formula and one-time calcining manufacture method

A manufacturing method, the technology of magnesia jade porcelain, applied in the field of ceramics, can solve the problems of poor product regularity and thermal shock resistance, reduce product strength, and narrow firing control, so as to improve product regularity and poor thermal shock resistance, reduce Deglazing tendency, effect of high firing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

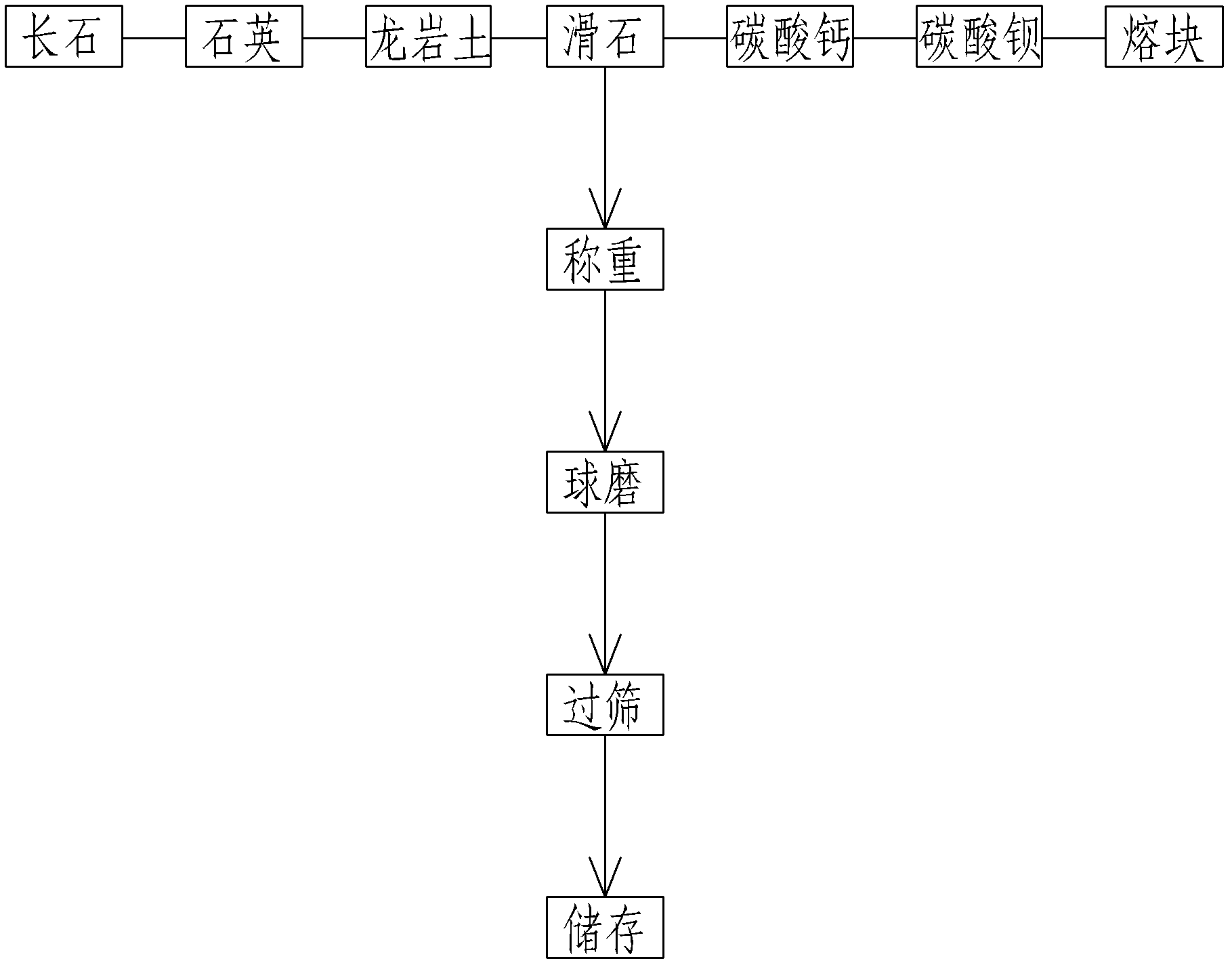

[0034] refer to figure 1 As shown, first weigh 40% of feldspar, 12% of quartz, 4% of dragon rock soil, 7% of talc, 4% of calcium carbonate, 18% of barium carbonate, and 15% of frit according to the glaze formula in Table 1. Store after sieving;

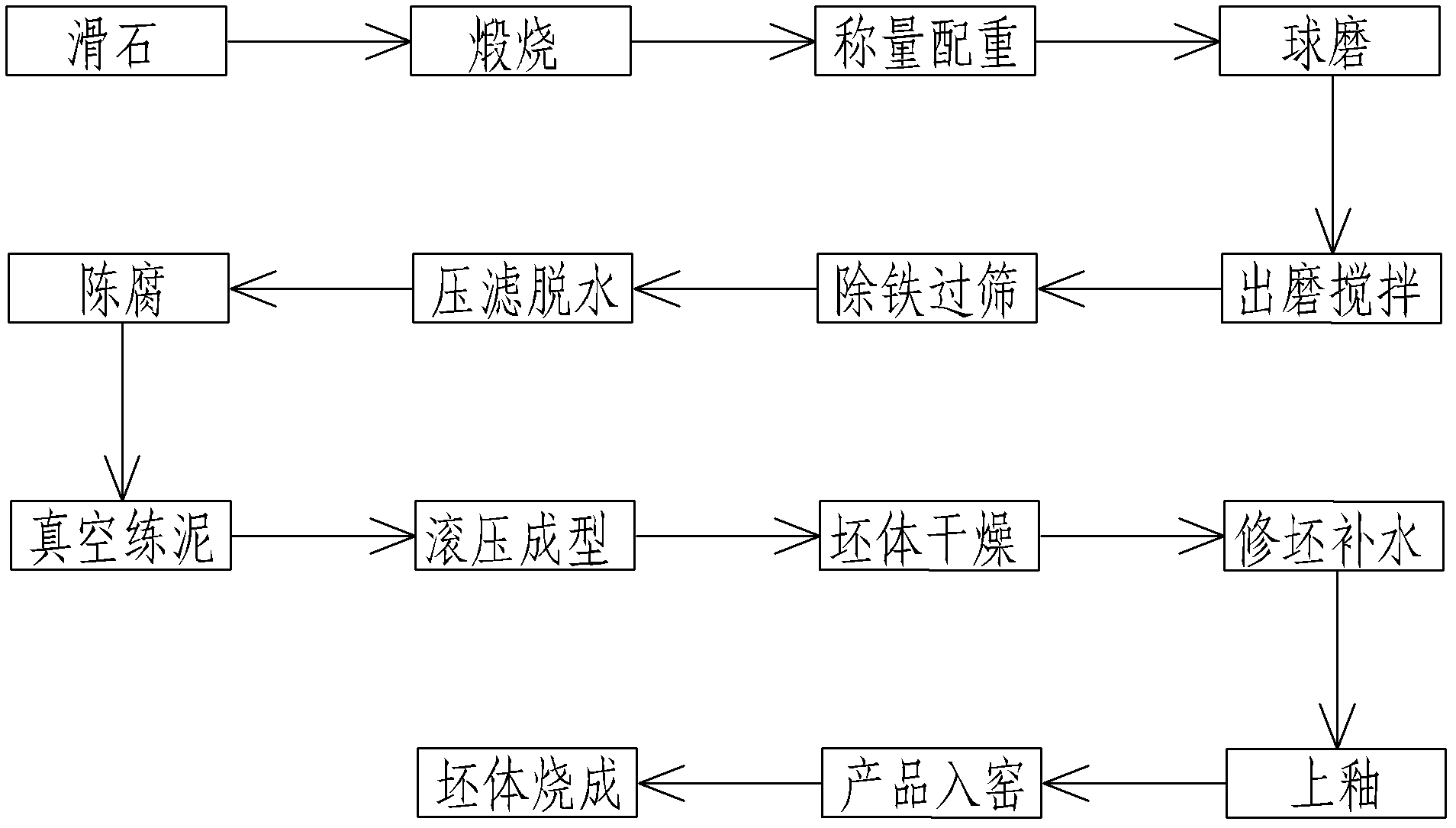

[0035] refer to figure 2 As shown, the production of magnesia jade porcelain is carried out according to the following production steps:

[0036] (1), calcining the talc raw material at 1200°C;

[0037] (2), weigh calcined talc 80%, magnesia clay 10%, feldspar 3%, bentonite 3%, kaolin 4%, sodium carboxymethyl cellulose 0.2% and carry out mixed ball milling according to the blank formula in Table 2;

[0038] (3), the mud material after the above-mentioned mixed ball milling is discharged and stirred, and the particles in the mud material are controlled to be less than 30um in iron removal and sieved;

[0039] (4), the mud material after deironing and sieving is subjected to pressure filtration dehydration, stale, vacuum mud refini...

specific Embodiment 2

[0042] refer to figure 1 As shown, first weigh 40% of feldspar, 12% of quartz, 4% of dragon rock soil, 7% of talc, 4% of calcium carbonate, 18% of barium carbonate, and 15% of frit according to the glaze formula in Table 1. Store after sieving;

[0043] refer to image 3 As shown, the production of magnesia jade porcelain is carried out according to the following production steps:

[0044] (1), calcining the talc raw material at 1200°C;

[0045] (2), weigh calcined talc 80%, magnesia clay 10%, feldspar 3%, bentonite 3%, kaolin 4%, sodium carboxymethyl cellulose 0.2% and carry out mixed ball milling according to the blank formula in Table 2;

[0046] (3), the mud material after the above-mentioned mixed ball milling is discharged and stirred, and the particles in the mud material are controlled to be less than 30um in iron removal and sieved;

[0047] (4), the mud material after deironing and sieving is subjected to pressure filtration dehydration, stale, vacuum mud refinin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com