Method for preparing mesoporous nano particles with special appearance based on anion surfactant

A technology of surfactants and nanoparticles, applied in the direction of nanotechnology, silicon dioxide, silicon oxide, etc., can solve the problems of the influence of nanoparticle size on the properties of nanomaterials, the influence of nanoparticle size and the performance of nanomaterials on morphology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

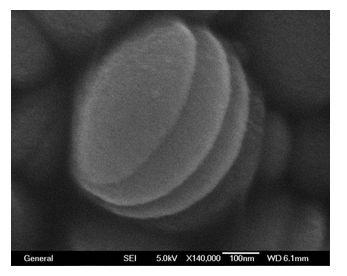

Image

Examples

Embodiment 1

[0020] Example 1: At 15°C, 1.0 mmol of Sar-Na, whose Chinese name is N-lauroyl sarcosine sodium, and whose English name is n-lauroylsarcosine sodium, is completely dissolved in 30 mL of In deionized water, add 2.0 mL of 0.1 M hydrochloric acid dropwise to slowly adjust the pH value to 6.0, stir vigorously for 30 minutes, add dropwise 1.0 mL of TEOS, and 0.1 mL of APMS. The name of TEOS is ethyl tetrasilicate, The name of the APMS is 3-aminopropyltrimethoxysilane; the resulting mixture was stirred at room temperature for 10 minutes, put in a kettle, left to age at 15°C for 2h, and then transferred the reaction kettle to an oven at 80°C for crystallization 20h. Shaking is prohibited during standing and transferring. The ratio of reaction is molar ratio namely: Sar-Na: HCl: TEOS: APMS: H 2 O;1:0.2:4.5:0.5:1667. After the crystallization, the reaction kettle was naturally cooled to room temperature, opened, and the white product was centrifuged at 8000 r / min, and washed repeate...

Embodiment 2

[0027] Example 2: At 14°C, 1.0 mmol of Sar-Na (N-lauroyl sarcosine sodium (n-lauroylsarcosine sodium, Sar-Na)) was completely dissolved in 30 mL of deionized water, and 2.0 mL of Slowly adjust the pH to 6.2 with 0.1M hydrochloric acid, stir vigorously for 30 minutes, add dropwise 1.0mL of TEOS (tetraethylorthosilicate) and 0.1mL of APMS (3-aminopropyltrimethoxysilane), and the resulting mixture is at room temperature Stirring was continued for 10 minutes, the kettle was installed, and aged at 14° C. for 2 hours, and then the reaction kettle was transferred to an oven at 80° C. for crystallization for 20 hours. Shaking is prohibited during standing and transferring. The ratio of reaction is molar ratio namely: Sar-Na: HCl: TEOS: APMS: H 2 O;1:0.2:4.5:0.5:1667. After the crystallization, the reaction kettle was naturally cooled to room temperature, opened, and the white product was centrifuged at 8000 r / min, and washed repeatedly with acetone and ethanol. Then dry at 40°C for...

Embodiment 3

[0032] Example 3: At 15°C, 1.0 mmol of Sar-Na (N-lauroyl sarcosine sodium (n-lauroylsarcosine sodium, Sar-Na)) was completely dissolved in 30 mL of deionized water, and 2.0 mL of Slowly adjust the pH to 6.6 with 0.1M hydrochloric acid, stir vigorously for 30 minutes, add dropwise 1.0mL of TEOS (tetraethylorthosilicate) and 0.1mL of APMS (3-aminopropyltrimethoxysilane), and the resulting mixture is Stirring was continued for 10 minutes, the kettle was installed, and aged at 15° C. for 2 hours, and then the reaction kettle was transferred to an oven at 80° C. for crystallization for 20 hours. Shaking is prohibited during standing and transferring. The ratio of reaction is molar ratio namely: Sar-Na: HCl: TEOS: APMS: H 2 0;1:0.2:4.5:0.5:1667. After the crystallization, the reaction kettle was naturally cooled to room temperature, opened, and the white product was centrifuged at 8000 r / min, and washed repeatedly with acetone and ethanol. Then dry at 40°C for more than 48h. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com