Intermittent extrusion coater

A coating machine, intermittent technology, applied in the field of coating, can solve the problems of irregular tail, thin tail, thick head at the intermittent position of coating, etc., to simplify the mechanism, improve the precision, and save the control system Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

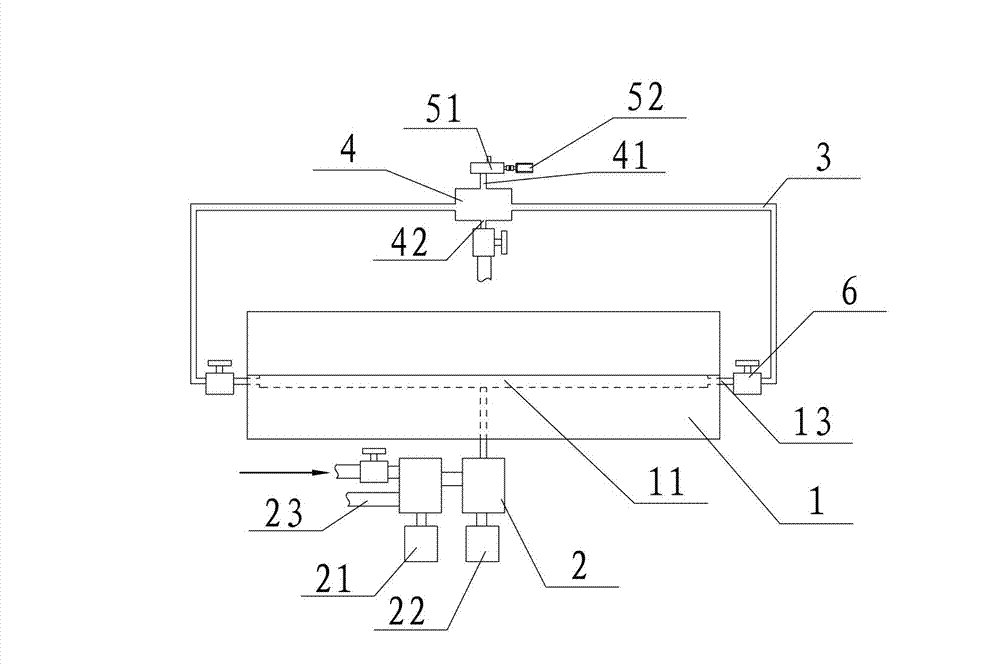

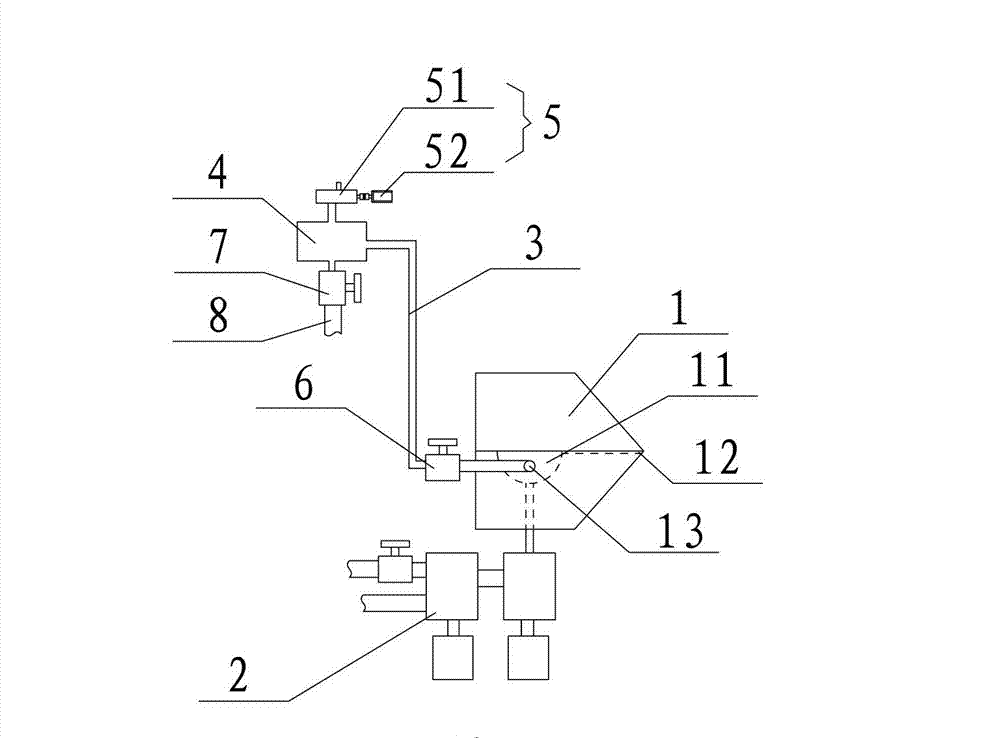

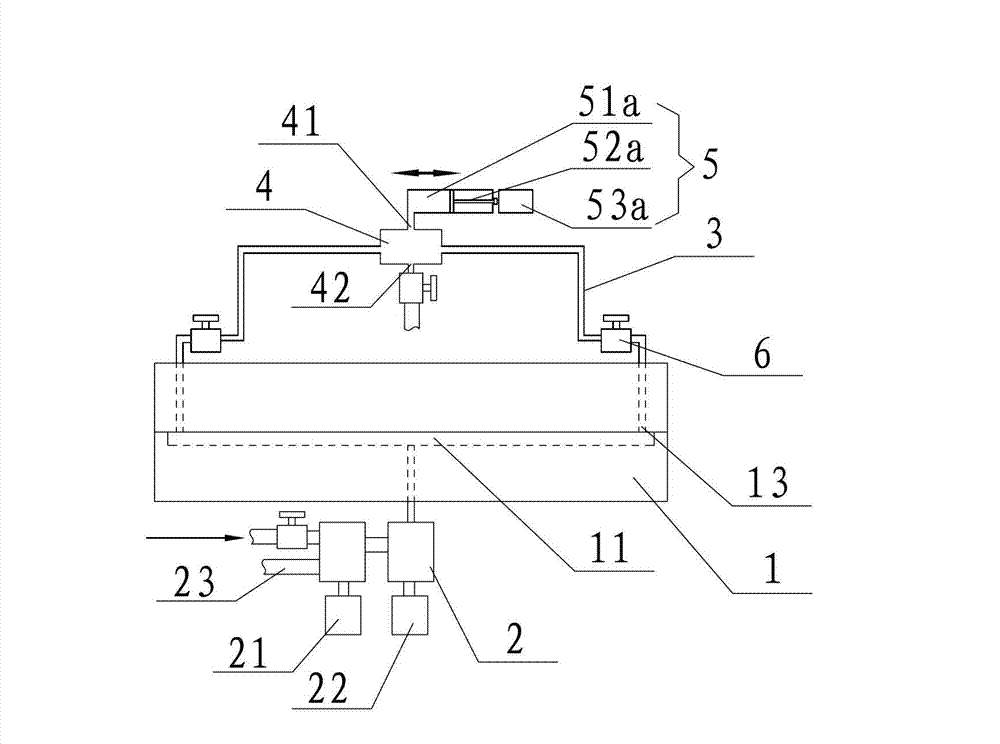

[0026] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0027] In the conventional intermittent extrusion coating method, the slurry is provided to the extrusion head, and then the slurry is intermittently applied to the substrate from the slit of the extrusion head, and the present invention provides an intermittent extrusion coating method. Cloth method, it also comprises the following steps in addition to conventional coating steps:

[0028] 1. When the extrusion head starts to apply slurry to the substrate, the slurry at the seam of the extrusion head is sucked back to make the slurry flow back;

[0029] 2. When the extrusion head stops applying slurry to the substrate, the slurry at the seam of the extrusion head is sucked back to make the slurry flow back.

[0030] The significance of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com